Wall surface machining device for building decoration engineering

A technology of architectural decoration engineering and processing equipment, which is applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., and can solve problems such as dust, worker injury, air pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

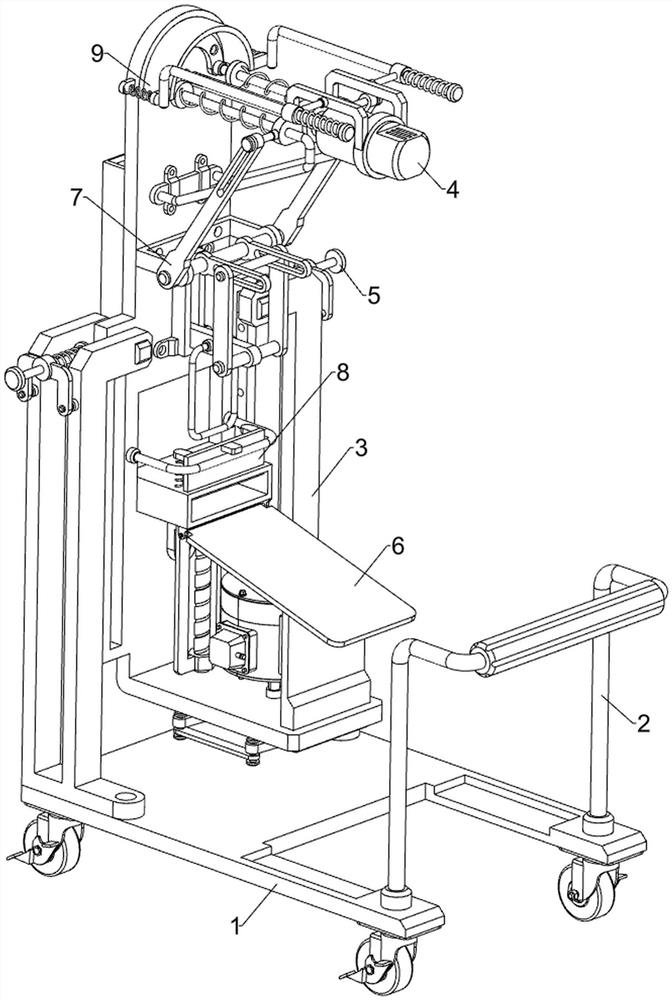

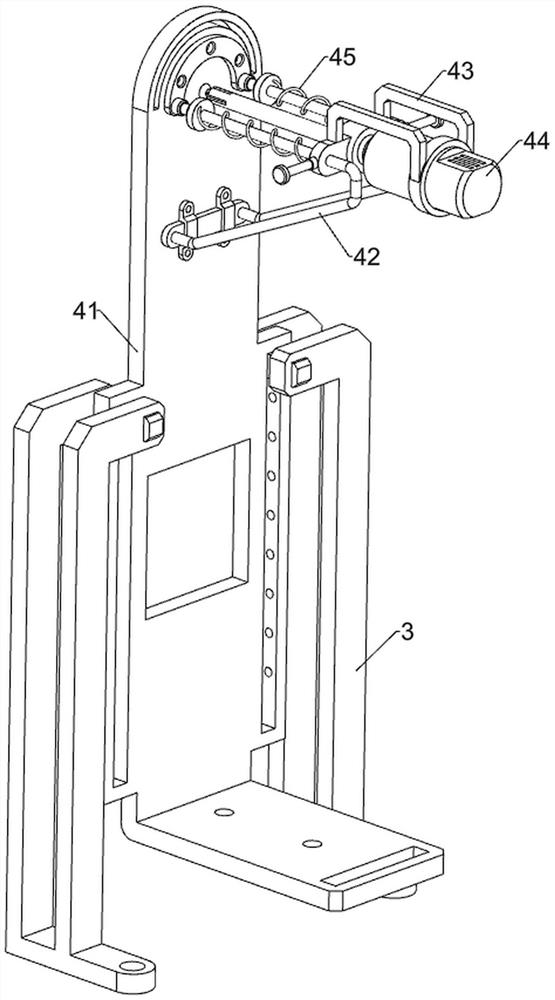

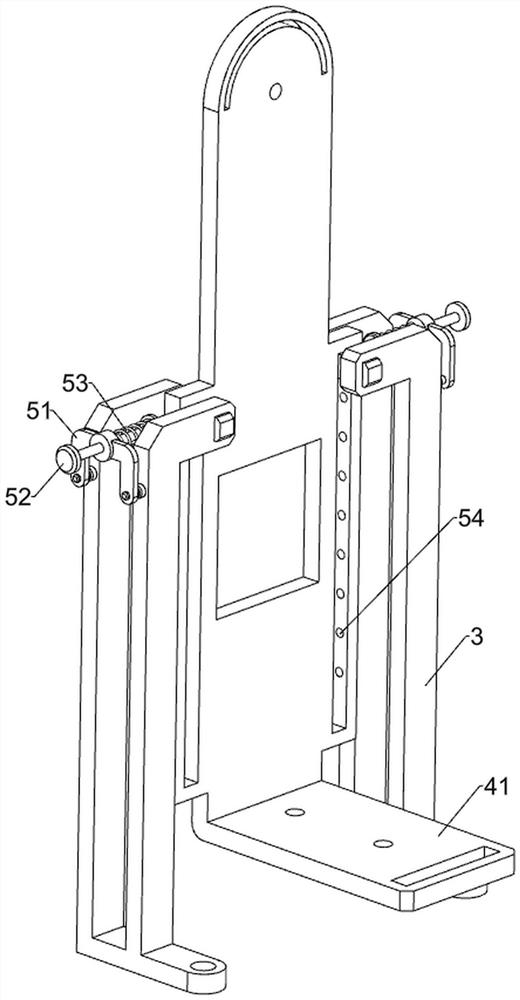

[0028] A wall processing device for building decoration engineering, such as Figure 1-3 As shown, it includes a mobile seat 1, a handle 2, a guide frame 3, a processing assembly 4 and a limit assembly 5. The upper right side of the mobile seat 1 is connected with a handle 2, and the left side of the mobile seat 1 passes through the front and rear sides. A guide frame 3 is fixedly connected to the bolt, and a processing assembly 4 is arranged between the guide frames 3 , and a limit assembly 5 is arranged on the guide frame 3 , and the limit assembly 5 cooperates with the processing assembly 4 .

[0029] When it is necessary to process the wall surface, control the handle 2 to move the moving seat 1, and then move the device to the edge of the wall, and then control the limit component 5 to adjust the position of the processing component 4, and no longer control the limit after the adjustment is completed Component 5, the limit component 5 automatically resets to fix the proce...

Embodiment 2

[0035] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Image 6 with Figure 7 As shown, a collection assembly 6 is also included, and the collection assembly 6 includes a collection frame 61, an inclined plate 62, a vertical plate 63, a reduction motor 64, a screw mandrel 65, a connecting block 66, a swing block 67 and a connecting plate 68, and the mounting plate 41 The upper sliding type is provided with a collection frame 61, the bottom right side of the collection frame 61 is rotatably connected with a slant plate 62, the right side of the mounting plate 41 is provided with a vertical plate 63, the vertical plate 63 is in contact with the slanting plate 62, and the mounting plate 41 The bottom is provided with a reduction motor 64, the bottom of the mounting plate 41 is rotatably connected with a screw 65, the underside of the collection frame 61 is connected with a connection block 66, the connection block 66 is connected with the screw 65 by thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com