Belt and chain universal type conveying line profile and conveying line

A wire profile and conveying line technology, applied in the field of conveying lines, can solve the problems of high procurement and processing costs, incompatibility, limited application scenarios, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

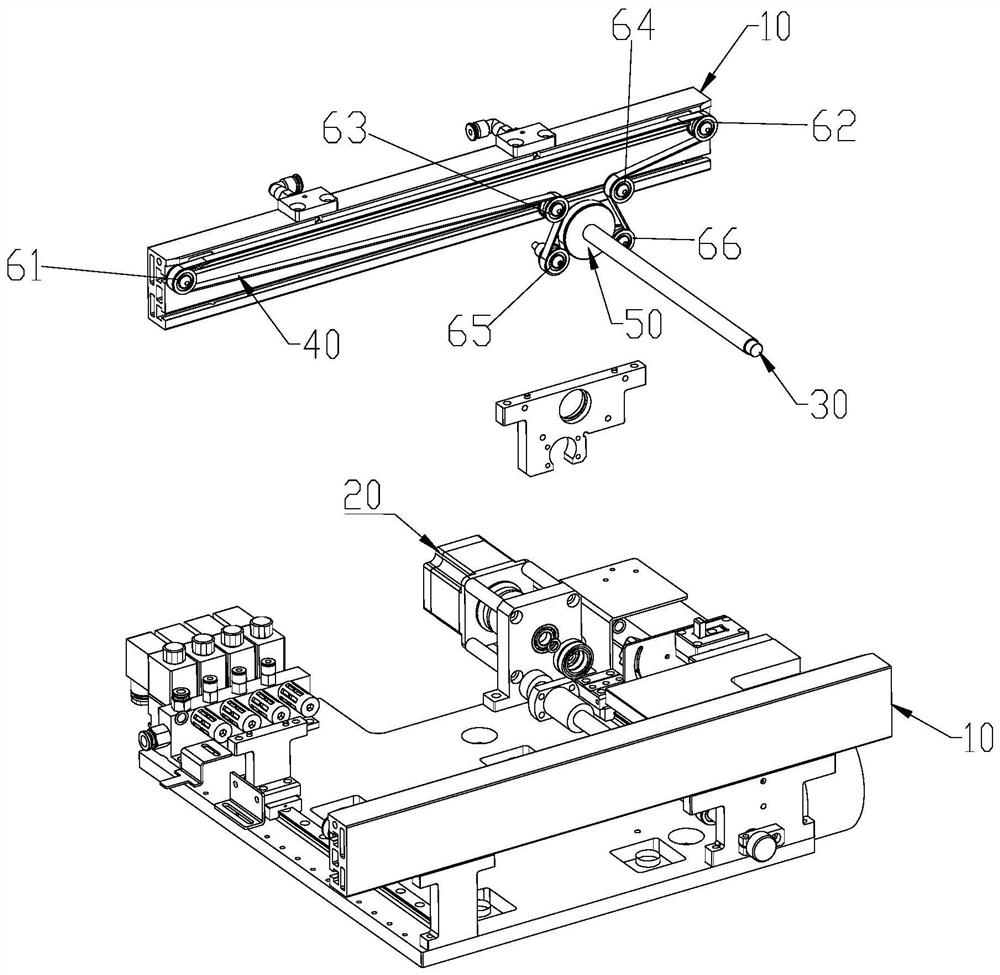

[0040] see Figure 6 to Figure 8 , shows a chain-driven conveying line provided in this embodiment, including two sets of chain conveying modules, a rotating motor 20 and a rotating shaft 30, and each set of flat belt conveying modules includes the above-mentioned conveying line profile 10, chain 40, gear 50 and some driven wheels.

[0041] The driven wheels include a first driven wheel 61 , a second driven wheel 62 , a third driven wheel 63 and a fourth driven wheel 64 . The first driven wheel 61 and the second driven wheel 62 are respectively rotatably installed at the two ends of the profile main body 1 (that is, the joint of the conveying line), and its horizontal height is located at the first chain guide groove 11 and the second chain guide groove 12; the third driven wheel 63 and the fourth driven wheel 64 are respectively located on the two outer sides of the gear 50 .

[0042] The first driven wheel 61, the second driven wheel 62, the third driven wheel 63 and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com