Steel plate composite beam operating platform

A technology for operating platforms and composite beams, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as difficulties in installing and dismantling cast-in-place bridge deck brackets and formwork, and worker safety cannot be guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

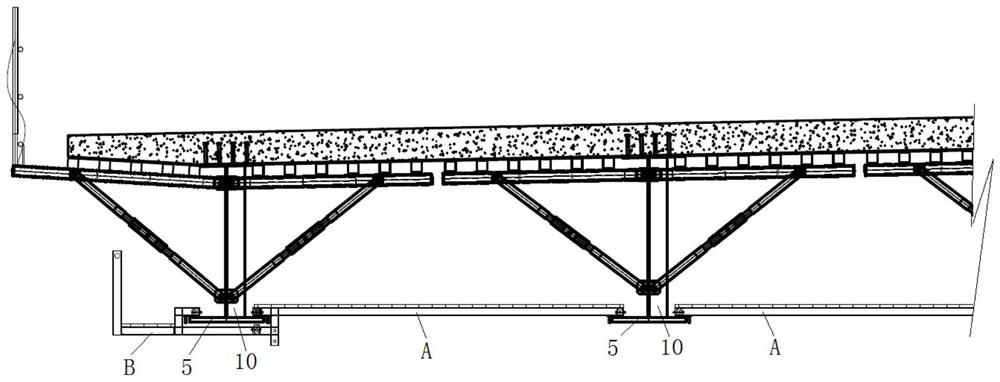

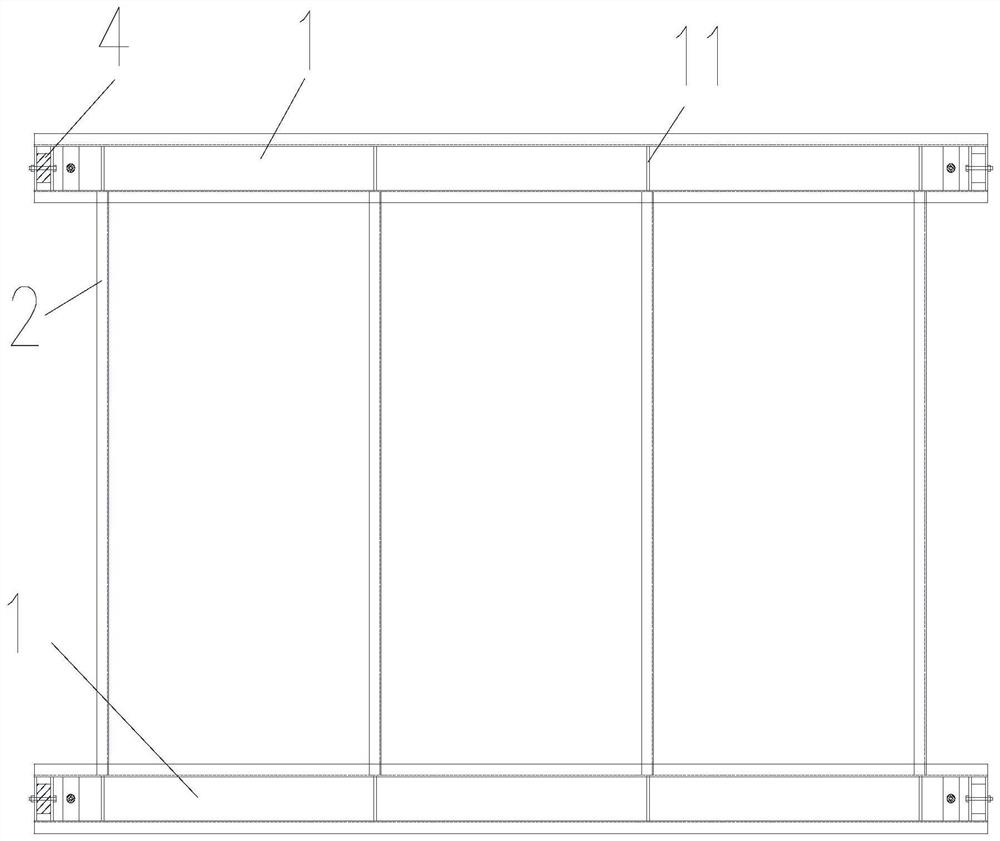

Embodiment 1

[0035] The steel plate composite beam operating platform A in the first embodiment provided by the application, such as Figure 1 to Figure 3 As shown, when the two ends of the main beam 1 are set higher than the walking platform, the rollers 4 are arranged on the top surface of the walking platform, that is, the two ends of the main beam 1 are arranged above the steel main beam bottom plate 5, and the rollers 4 at the two ends of the main beam 1 are set On the steel girder floor 5 top surfaces of two adjacent steel girders, that is, the rollers 4 at both ends of the main girder 1 travel on the top surfaces of the steel girder bottom plates 5 . Because the longitudinal girders of the same steel girder run through the longitudinal direction of the bridge, after the steel plate composite girder operating platform is installed on the steel girder bottom plate 5, one installation can be realized, and all parallel connections, The installation and disassembly of cast-in-place bridg...

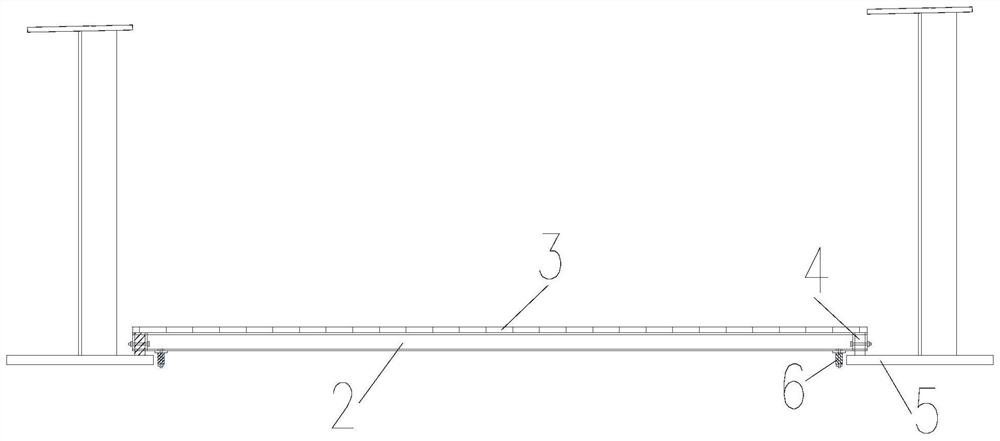

Embodiment 2

[0038] The steel plate composite beam operating platform B in the second embodiment provided by the application, such as figure 1 , Figure 4 and Figure 5As shown, when the main beam 1 is set lower than the walking platform, the main beam 1 is arranged under the steel main beam bottom plate 5, and two roller connectors 7 connected with the rollers 4 are arranged at both ends of the main beam 1, and the two roller connectors 7 are connected The rollers 4 are arranged on two opposite and adjacent walking platforms, that is, arranged on the top surface of the steel main beam floor 5 on both sides of the same longitudinal beam along the bridge, and the roller connectors 7 are arranged on the two ends of the main beam 1 Above, and one end away from the main beam extends to the longitudinal beam 10 in the steel main beam, and the roller 4 is arranged at the end of the extension section of the roller connector 7 to the steel main beam longitudinal beam 10, so as to ensure that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com