Steel pipe pile foundation and construction method thereof

A technology of pile foundation and steel pipe pile is applied in the field of steel pipe pile foundation and its construction, which can solve the problems of high environmental protection requirements, broken piles, and easy concrete inclusion of mud in the pile body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

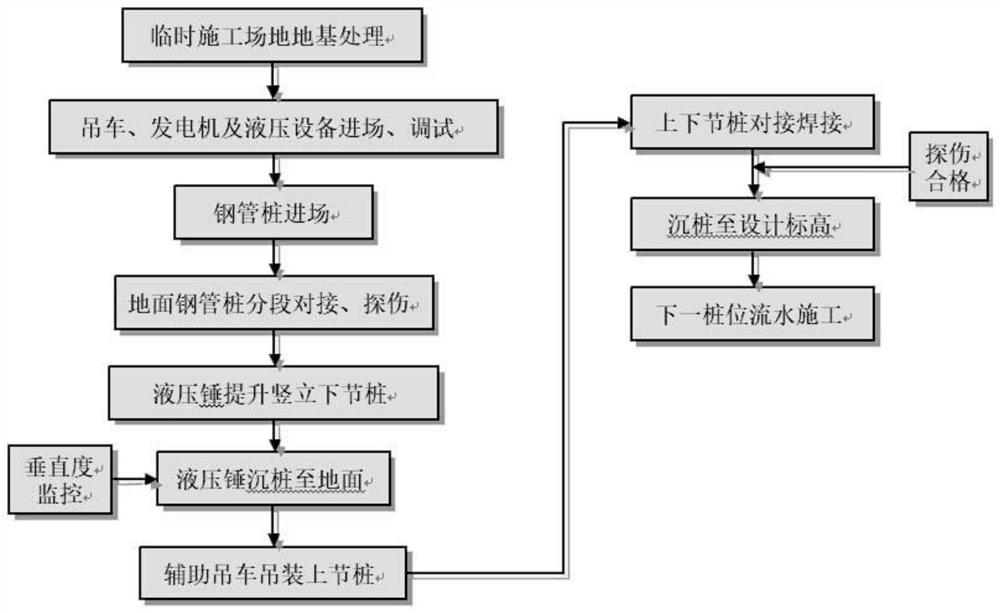

Method used

Image

Examples

Embodiment 1

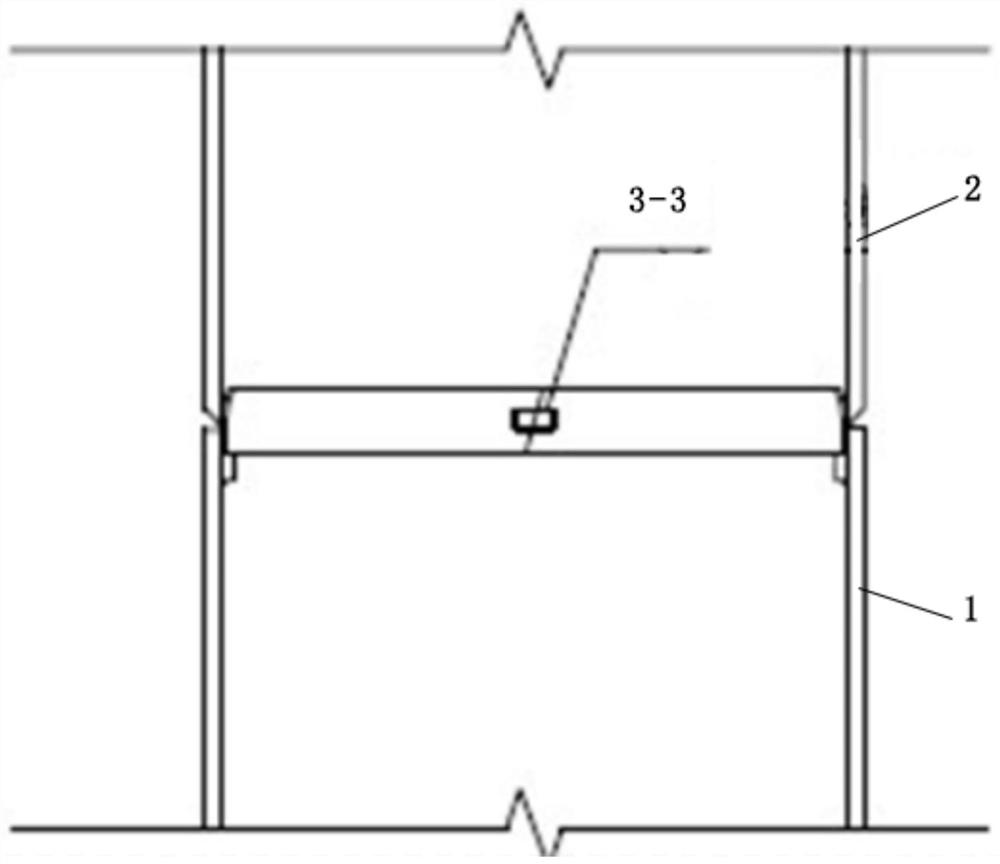

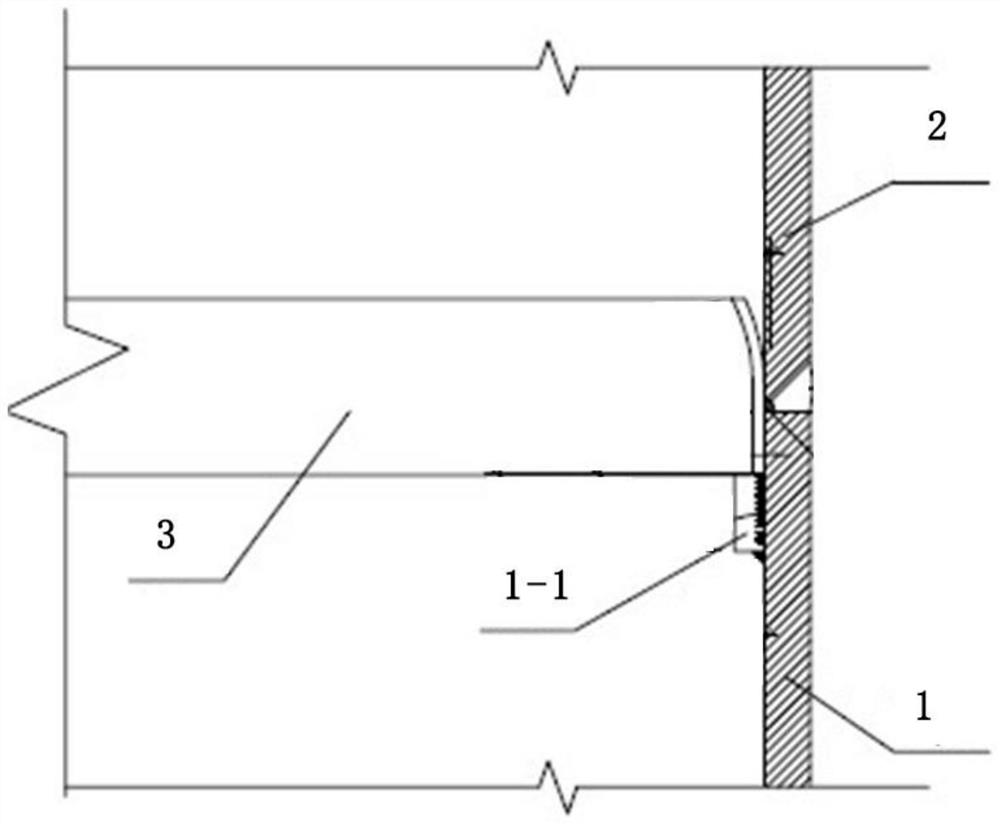

[0054]Example 1: When the upper stump 2 is 30m, the wall thickness is 12cm, the outer diameter is 700mm, the lower pile 1 is 30m, the wall thickness is 18cm, and the outer diameter is 700mm:

[0055]During the lifting of the power station, the 180-ton track crane is selected, the arm length is 43.5 meters, the rotary radius r = 20.5 meters, the rated weight = 32.2 tons, the power station weight g = 16.5 tons, the hook group is 2 tons. Q>G + 2 = 18.5 tons. The load rate is 57.5%, meeting the requirements.

[0056]During the next pile 1, the 180 ton crawler crane, the arm length is 43.5 meters, the rotary radius r = 18 meters, the rated weight q = 38.6 tons. The total weight of the hydraulic hammer G = 22 tons, the hook group weight is 2 tons, and the next steel pipe is 7 tons. Q>G + 2 + 7 = 31 tons. The load rate is 80.3%, meeting the requirements.

[0057]During the lifting pile of last pile 2, 180 tons of crawler crane, the arm length is 43.5 meters, the radius R = 18 m, the rated weight = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com