Sensor production line remote calibration method and system

A calibration method and a calibration system technology are applied in the field of remote calibration method and system of sensor production line, which can solve the problems of remote calibration station of sensor production line, error-proof calibration instruction programming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1 of the present invention proposes a remote calibration method for sensor production lines, which can be applied to the remote calibration system for sensor production lines described in Embodiment 1 to realize LDW (lane departure warning system), MRR (medium range radar monitoring system), Sensor calibration for automotive ADAS modules or systems such as BSD (Blind Spot Monitoring System).

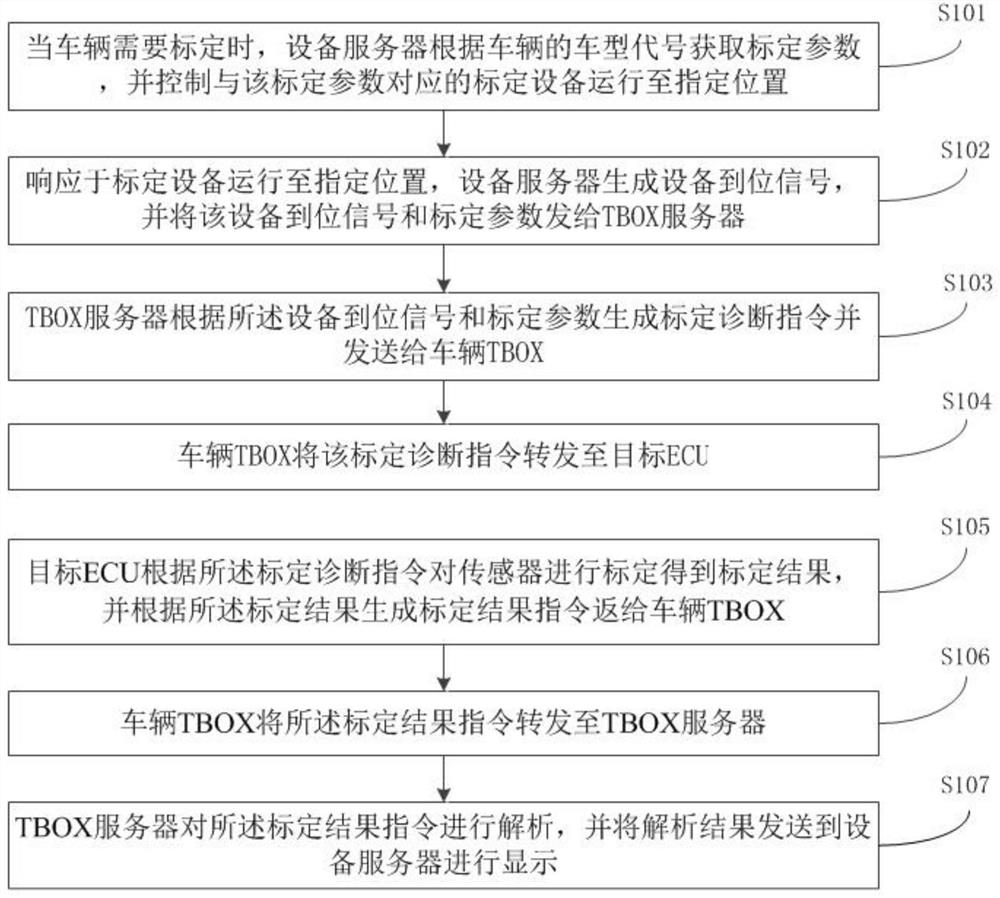

[0049] figure 1 It is a flowchart of a remote calibration method for a sensor production line in Embodiment 1, see figure 1, the method includes the following steps S101 to S106:

[0050] Step S101 , when the vehicle needs to be calibrated, the device server obtains the calibration parameters according to the model number of the vehicle, and controls the calibration device to run to a designated location.

[0051] For example, during the final assembly of the car in the step, the vehicle enters the calibration station, that is, the testing station, and the device serv...

Embodiment 2

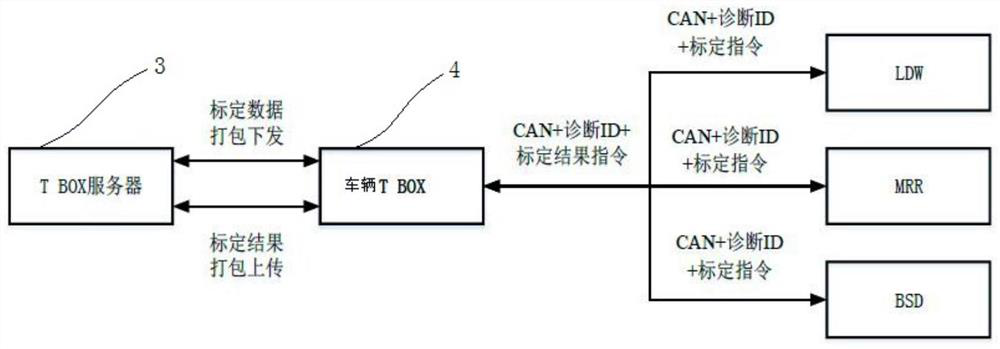

[0095] Such as Figure 4 As shown, Embodiment 2 of the present invention proposes a sensor production line remote calibration system, which is used to implement the sensor production line remote calibration method described in Embodiment 1. The system includes a device server 1, a calibration device 2, and a TBOX server 3 and vehicle TBOX4.

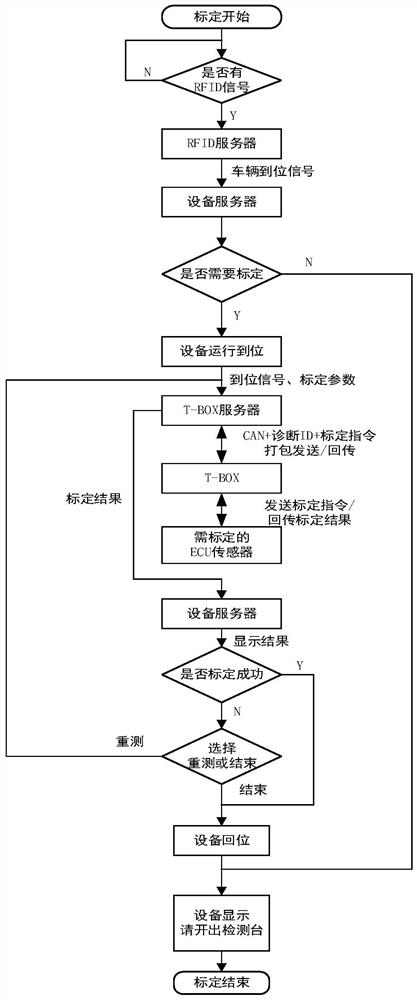

[0096] In a preferred embodiment, as Figure 5 As shown, the system further includes: RFID device 5 and RFID server 6 .

[0097] The RFID device 5 is used to identify the RFID beacon on the vehicle to obtain the vehicle VIN code when the vehicle enters the calibration station, and judge whether the vehicle is a legal vehicle according to the vehicle VIN code, and if it is legal, then the vehicle VIN code Send to RFID server 6.

[0098] The RFID server 6 is used to judge whether the vehicle is a legal vehicle according to the VIN code of the vehicle, and if it is a legal vehicle, then send a vehicle arrival signal to the device server 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com