A servo-actuated upender

A turning machine and follow-up technology, applied in the field of follow-up turning machines, can solve the problems of long preparation time, complicated operation, troublesome maintenance, etc., and achieve the effects of convenient operation, safe and reliable operation, and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

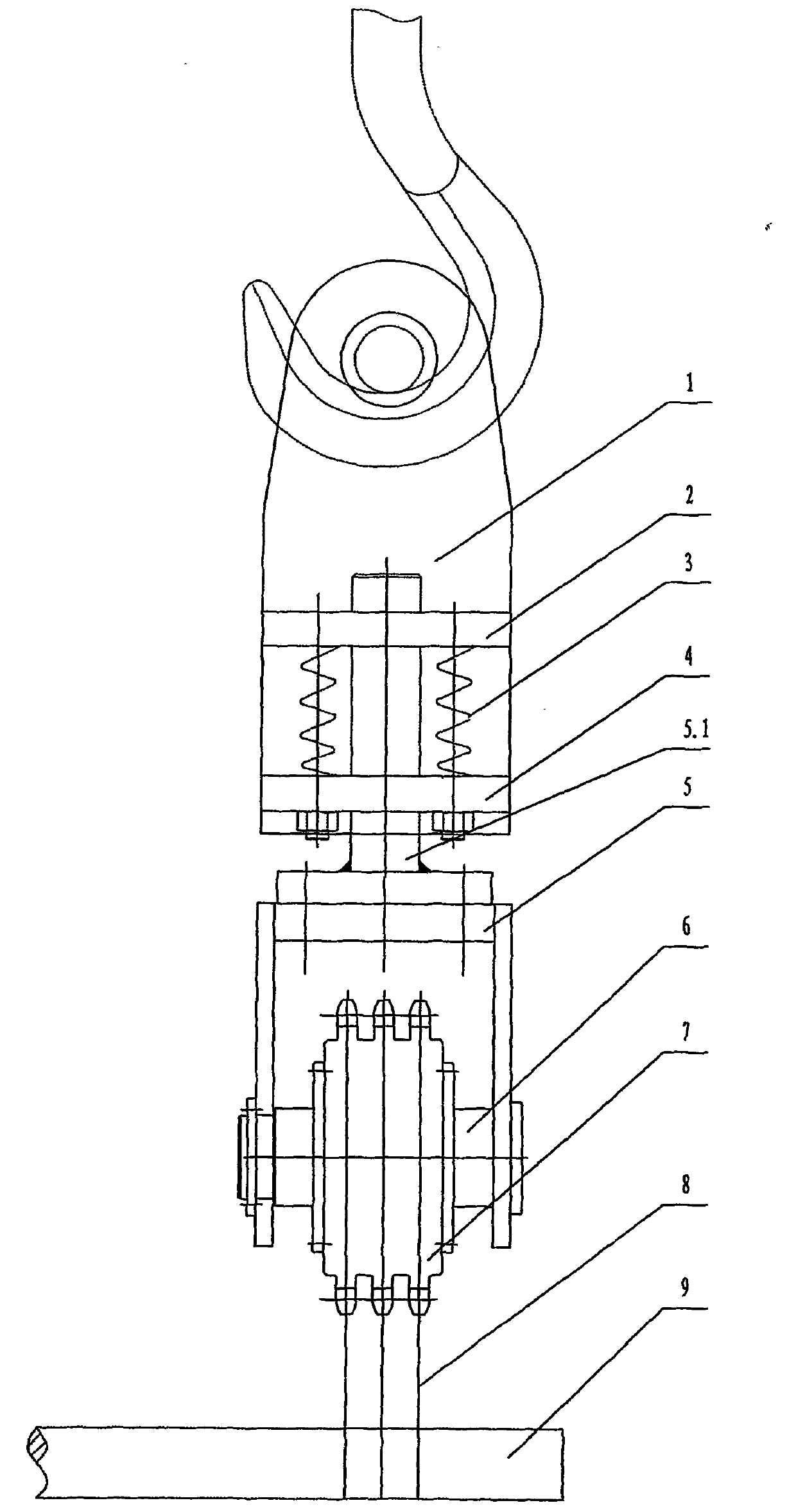

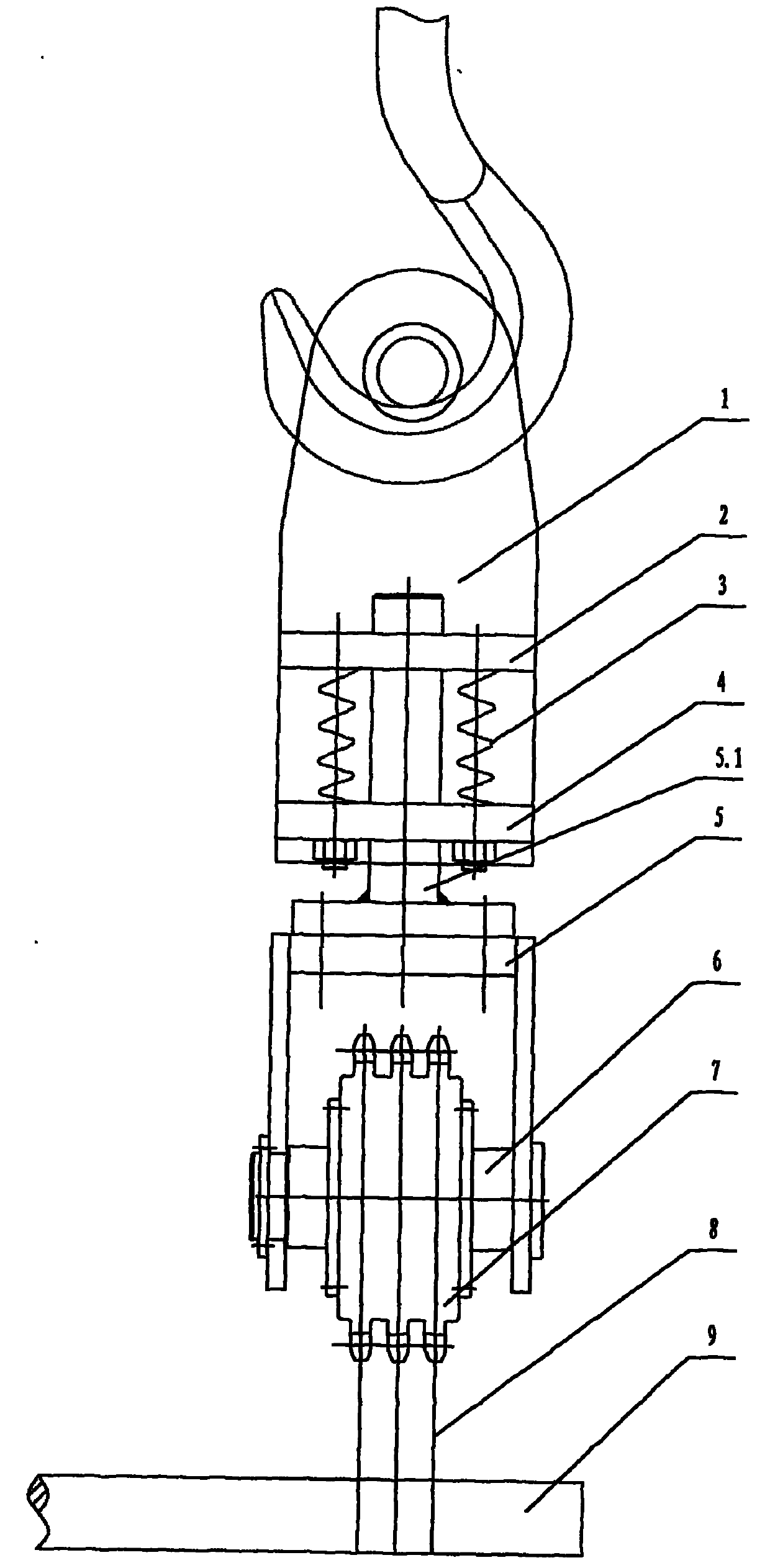

[0009] see figure 1 , The follow-up turning machine that the present invention relates to is mainly made up of upper frame 1, upper platen 2, spring 3, lower platen 4, lower frame 5, axle 6, sprocket wheel 7 and chain 8.

[0010] The upper pressing plate 2 and the lower pressing plate 4 are arranged in parallel up and down, a spring 3 is arranged between the two, and the lower pressing plate 4 is fixed on the bottom end of the upper frame 1 .

[0011] The top of the lower frame 5 is provided with a fixed rod 5.1, and the fixed rod 5.1 passes through the lower pressing plate 4 and is fixed on the upper pressing plate 2.

[0012] The sprocket 7 is horizontally fixed on the lower frame 5 by the shaft 6, and the sprocket 7 is provided with a chain 8.

[0013] working principle:

[0014] During use, the upper pressing plate 2 is lifted, and one end of the workpiece 9 is lifted through the chain 8 support. When the forging manipulator is overturned, the workpiece 9 can be overtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com