Preparation method and preparation device of flexible electronic device

A technology for flexible electronic devices and preparation devices, which can be applied in the fields of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., and can solve problems such as cracks or wrinkles in sensitive cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a method for preparing a flexible electronic device, comprising the following steps:

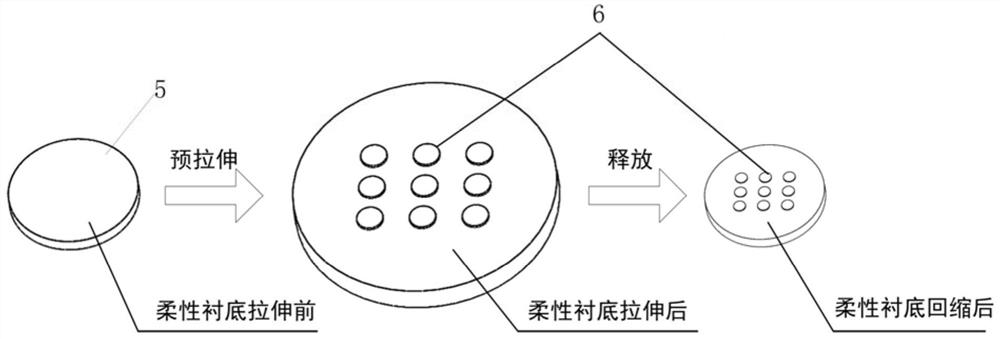

[0041] Stretch the flexible substrate 5 uniformly along the outer contour direction;

[0042] After the flexible substrate 5 is stretched in place, in the stretched state of the flexible substrate 5, the material of the sensitive unit 6 is coated on the surface of the flexible substrate 5 in an array;

[0043] After the material of the sensitive unit 6 on the flexible substrate 5 is solidified, the flexible substrate 5 is released to shrink back to its original size.

[0044] In this preparation method, the flexible substrate 5 is uniformly stretched along the outer contour direction of the flexible substrate 5, so that the flexible substrate 5 is deformed and extended outward in the contour direction; The flexible substrate 5 is then released to shrink back to its original size. Since the flexible substrate 5 is uniformly deformed outward along the directio...

Embodiment 2

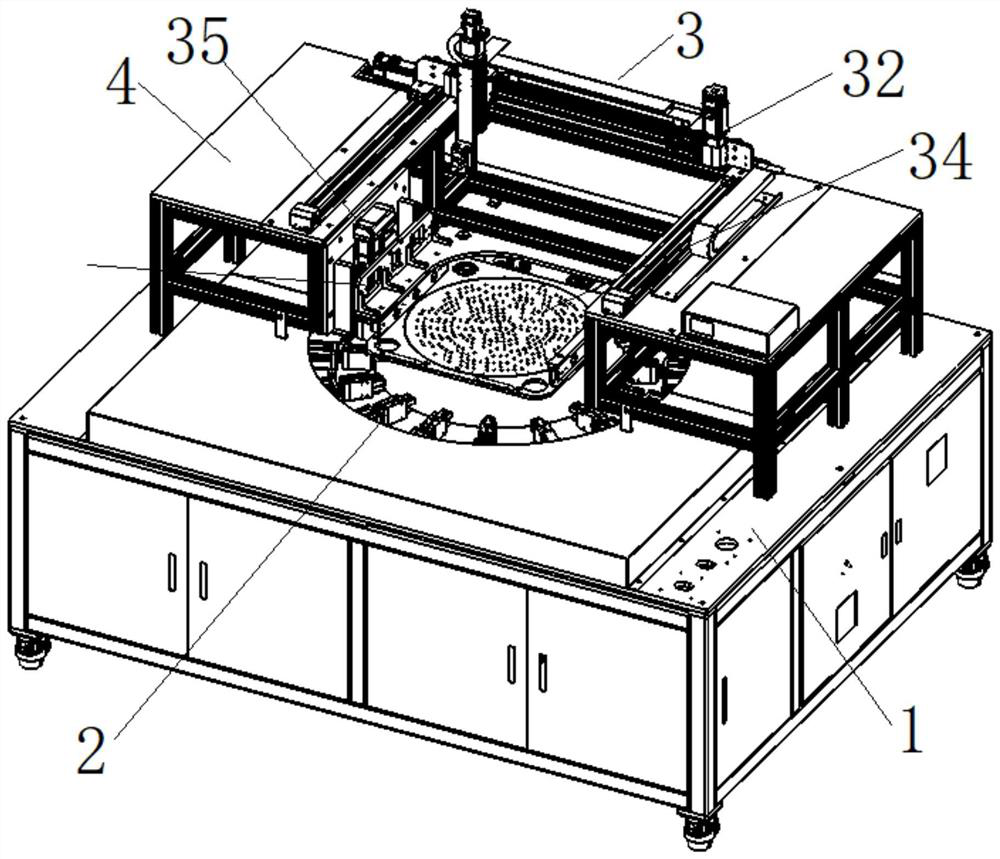

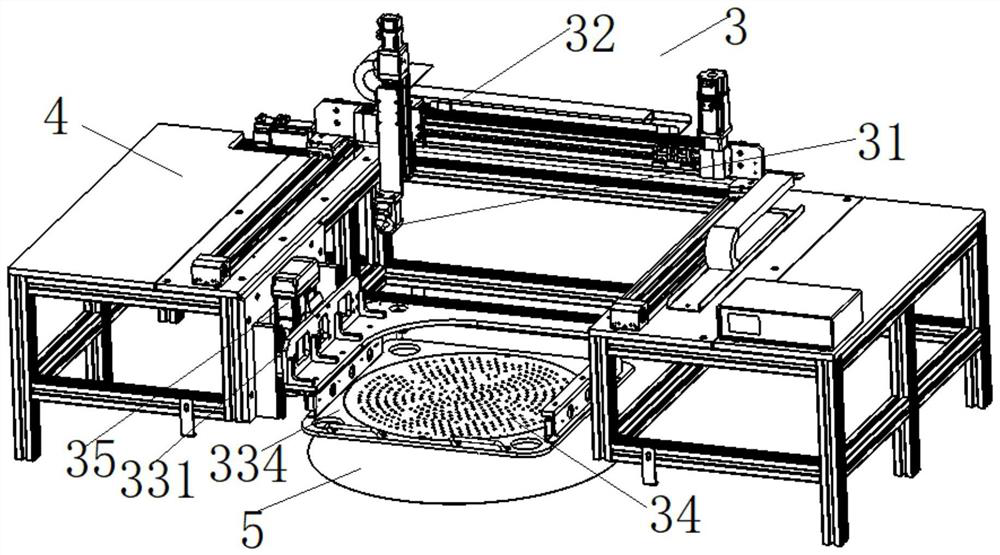

[0051] This embodiment provides a preparation device for flexible electronic devices, such as figure 2 As shown, it includes a base 1 , at least three sets of stretching components 2 and spraying components 3 .

[0052] Wherein, the upper part of the base 1 is provided with an inwardly recessed recessed area; the flexible substrate 5 is suitable to be placed in the recessed area; at least three sets of tensile components 2 are arranged on the base 1 and are evenly distributed along the contour direction of the recessed area, The stretching assembly 2 is suitable for clamping the flexible substrate 5 in at least three directions and uniformly stretching or releasing it; the spraying assembly 3 is arranged on the top of the base 1; the spraying assembly 3 includes a spray head 31, and the spray head 31 is suitable for The material of the sensitive unit 6 is coated on the surface of the flexible substrate 5 in an array.

[0053] In the preparation device of the flexible electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com