A base film for TPU high-transparency paint protection film, TPU film and preparation method thereof

A technology of protective film and base film, applied in the field of film manufacturing, can solve the problems such as the lack of perfect unity of lamination effect and anti-yellowing performance, and achieve good product quality stability, excellent high elasticity, and easy to control the process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

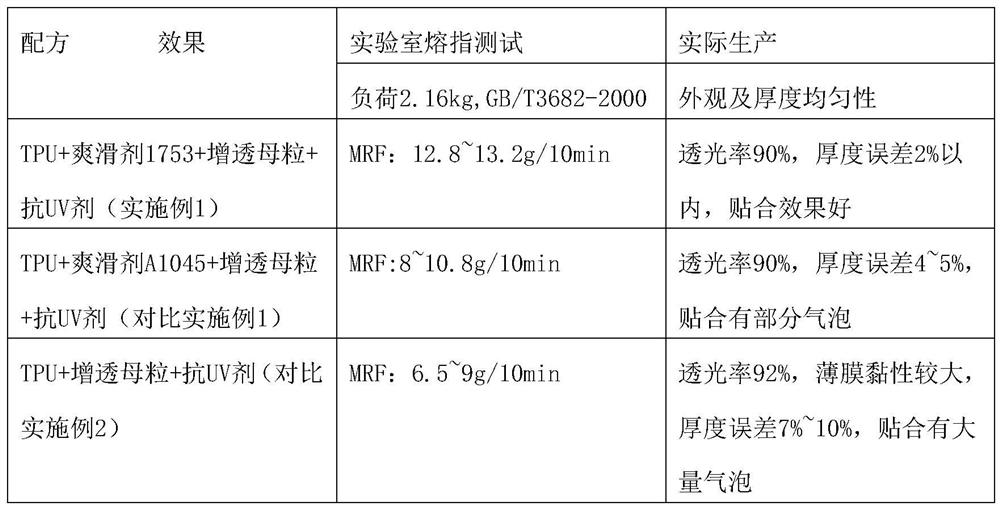

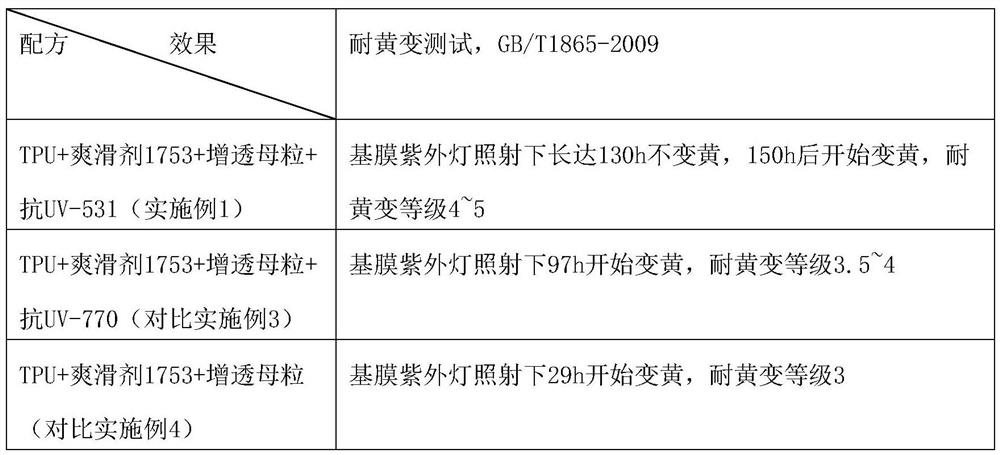

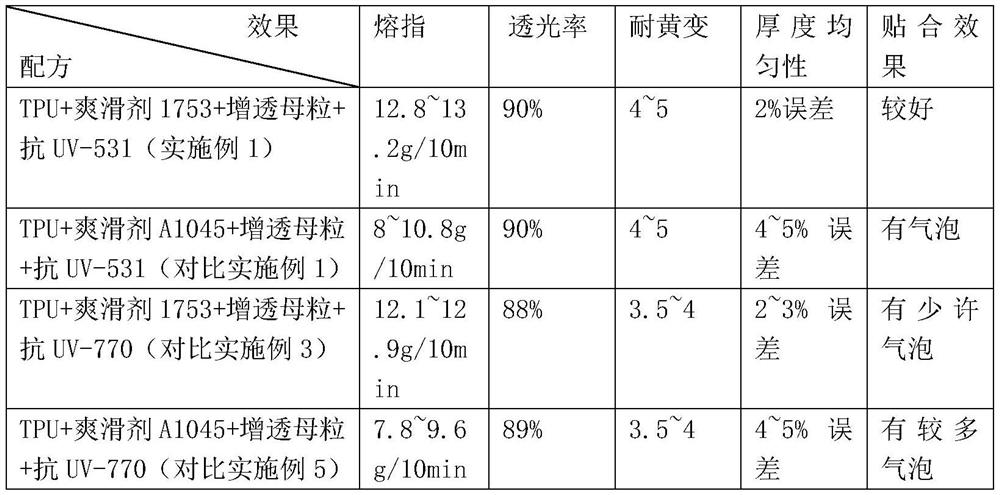

Examples

Embodiment 1

[0039] 1. Material mixing: Firstly, the polyether-type TPU raw material with a hardness of 90A and functional additives such as slip agent are fully mixed in a high-speed mixer and dispersed evenly. The ratio can be 86% TPU particles, 5% slip agent 1753, 3% antireflection masterbatch, 6% anti-UV-531 agent

[0040] 2. Drying and dehumidification of materials: Put the above mixed materials into a dehumidifier for 4 hours and set the temperature at 85°C

[0041] 3. Processing of TPU casting film: The above-mentioned fully dried materials are made into casting film through casting equipment.

[0042] Heating and mixing are carried out in three sections of the screw:

[0043] The temperature of the first feeding section is set at: 170°C for 8 minutes;

[0044] The temperature of the second compression section is set at 183°C for 15 minutes;

[0045] The temperature of the third discharge section is set at: 189°C for 5 minutes;

[0046] Die head temperature setting: 185°C;

[0...

Embodiment 2

[0052] 1. Material mixing: Firstly, the raw material of polyester TPU with a hardness of 85A and functional additives such as slip agent are fully mixed in a high-speed mixer and dispersed evenly. The ratio can be 84% TPU particles, 4% slip agent 1753, 6% antireflection masterbatch, 6% anti-UV-531 agent

[0053] 2. Drying and dehumidification of materials: Put the above mixed materials into a dehumidifier for 4 hours and set the temperature at 90°C

[0054] 3. Processing of TPU casting film: The above-mentioned fully dried materials are made into casting film through casting equipment.

[0055] Heating and mixing are carried out in three sections of the screw:

[0056] The temperature of the first feeding section is set at: 175°C for 8 minutes;

[0057] The temperature of the second compression section is set at: 180°C for 13 minutes;

[0058] The temperature of the third discharge section is set at: 190°C for 5 minutes;

[0059] Die head temperature setting: 195°C;

[00...

Embodiment 3

[0065] 1. Material mixing: Firstly, the polyester TPU raw material with a hardness of 90A and functional additives such as slip agent are fully mixed in a high-speed mixer and dispersed evenly. The ratio can be 90% TPU particles, 3% slip agent 1753, 2% antireflection masterbatch, 5% anti-UV-531 agent

[0066] 2. Drying and dehumidification of materials: Put the above mixed materials into a dehumidifier to dry for 4 hours, and set the temperature at 85°C;

[0067] 3. Processing of TPU casting film: The above-mentioned fully dried materials are made into casting film through casting equipment.

[0068] Heating and mixing are carried out in three sections of the screw:

[0069] The temperature of the first feeding section is set at: 185°C for 5 minutes;

[0070] The temperature of the second compression section is set at: 195°C for 8 minutes;

[0071] The temperature setting of the third discharge section is: 200°C for 3 minutes;

[0072] Die head temperature setting: 195°C; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com