Permanent magnet linear synchronous motor feeding device

A permanent magnet linear synchronization and feeding device technology, applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve problems such as motor damage, easily scratched coils, and difficult installation of rotors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

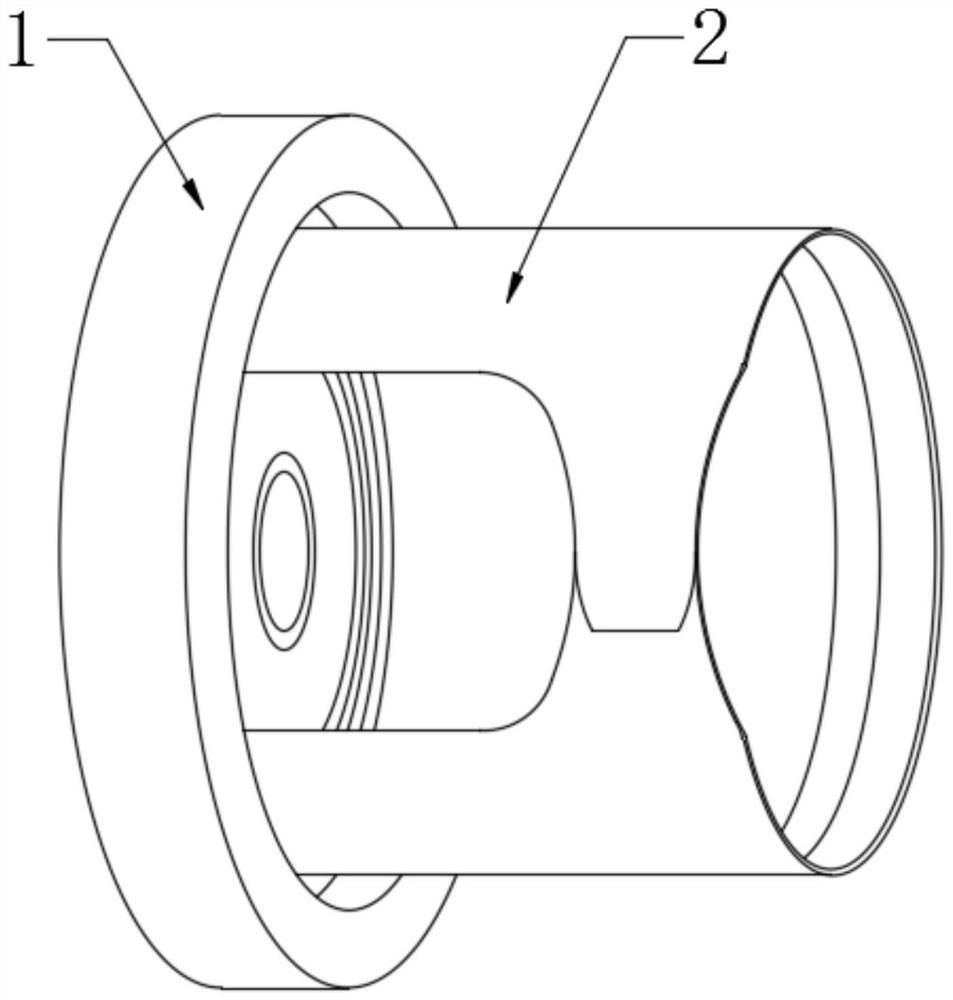

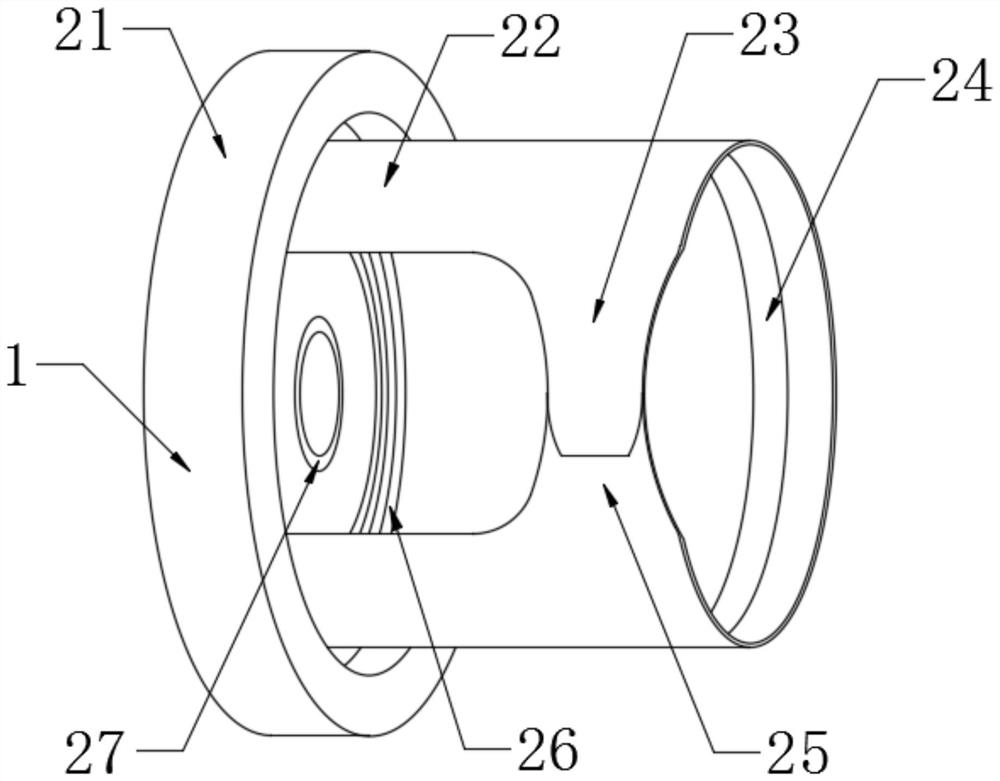

[0021] see Figure 1-Figure 5 , The present invention provides a technical solution: a permanent magnet linear synchronous motor feeding device, including a feeder main body 1 and a rotor feeding mechanism 2 , and the rotor feeding mechanism 2 is arranged inside the feeder main body 1 .

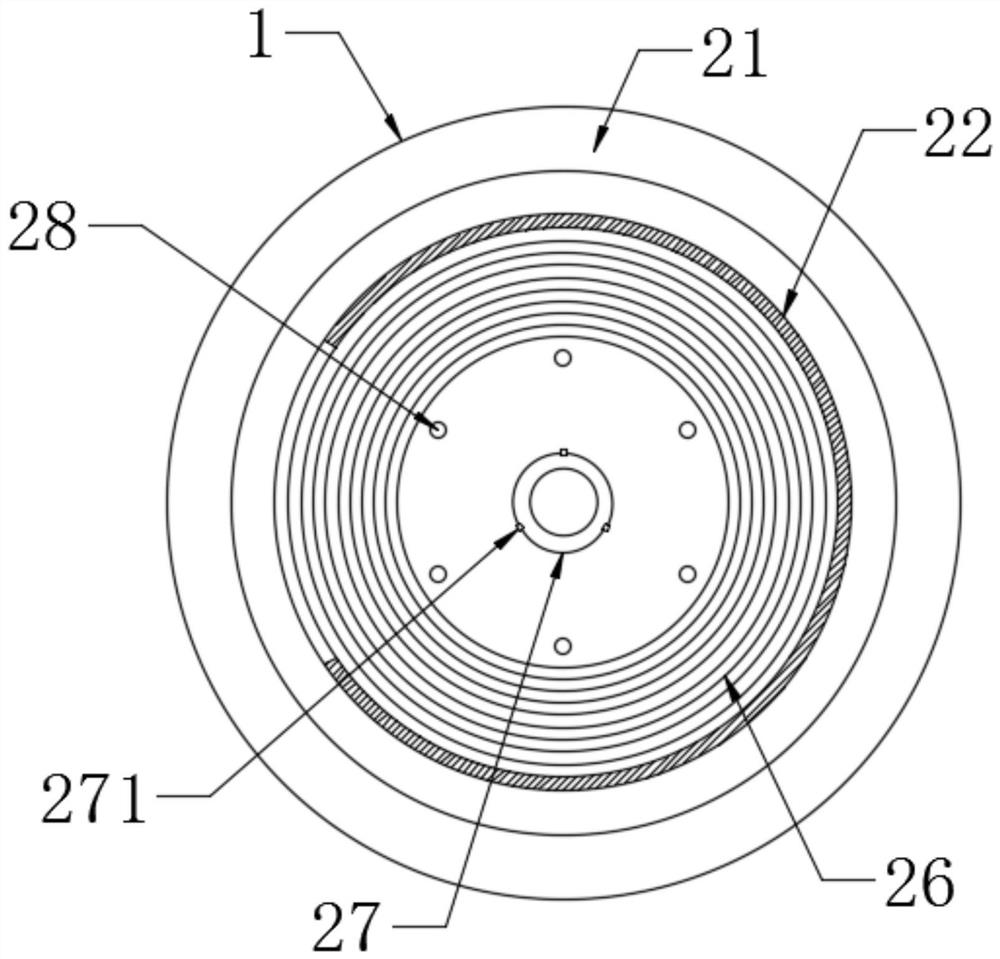

[0022] The rotor feeding mechanism 2 includes a bottom bracket 21, an embedded protection slide 22, a first buckle 23, a magnetic sheet 24, a second buckle 25, a matching groove 26, a bearing seat 27, a discharge jack 28, a rubber plug 221 and a label. Positive pin 271, bottom support 21 is installed on the left side of feeder main body 1, and bottom support 21 right end surface is provided with matching groove 26, and the right side of matching groove 26 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com