Method for producing metal particle composition, and metal particle composition

A technology of metal particles and manufacturing methods, applied in metal processing equipment, grain processing, electrical components, etc., can solve problems such as volume expansion, deterioration of charge and discharge characteristics, and high resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

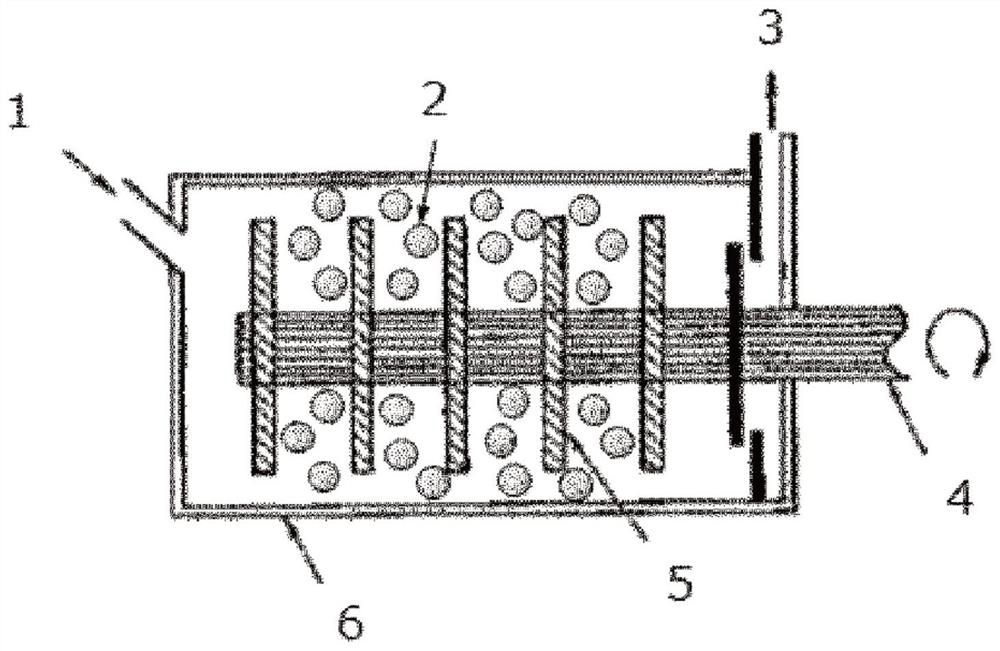

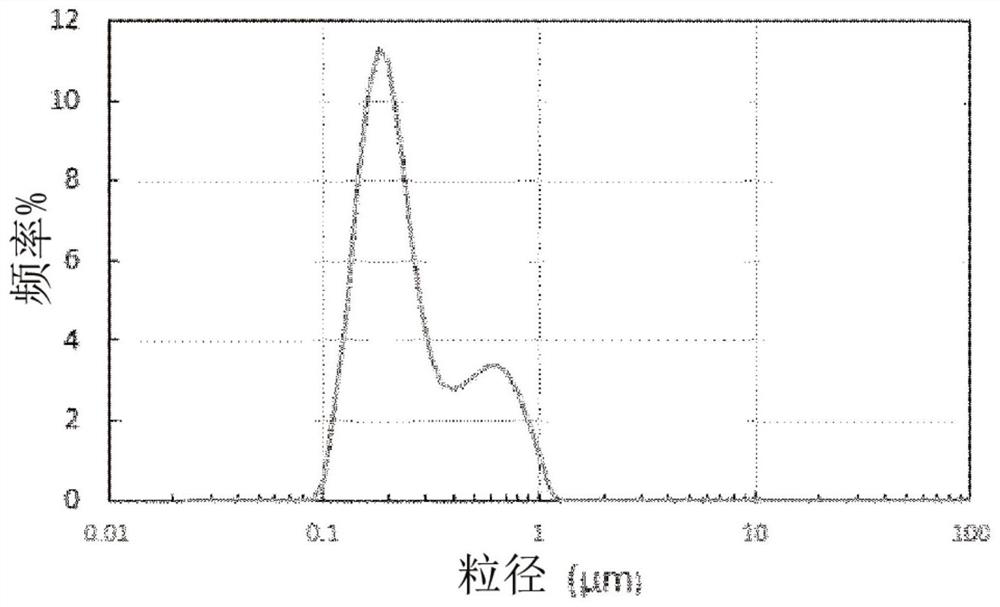

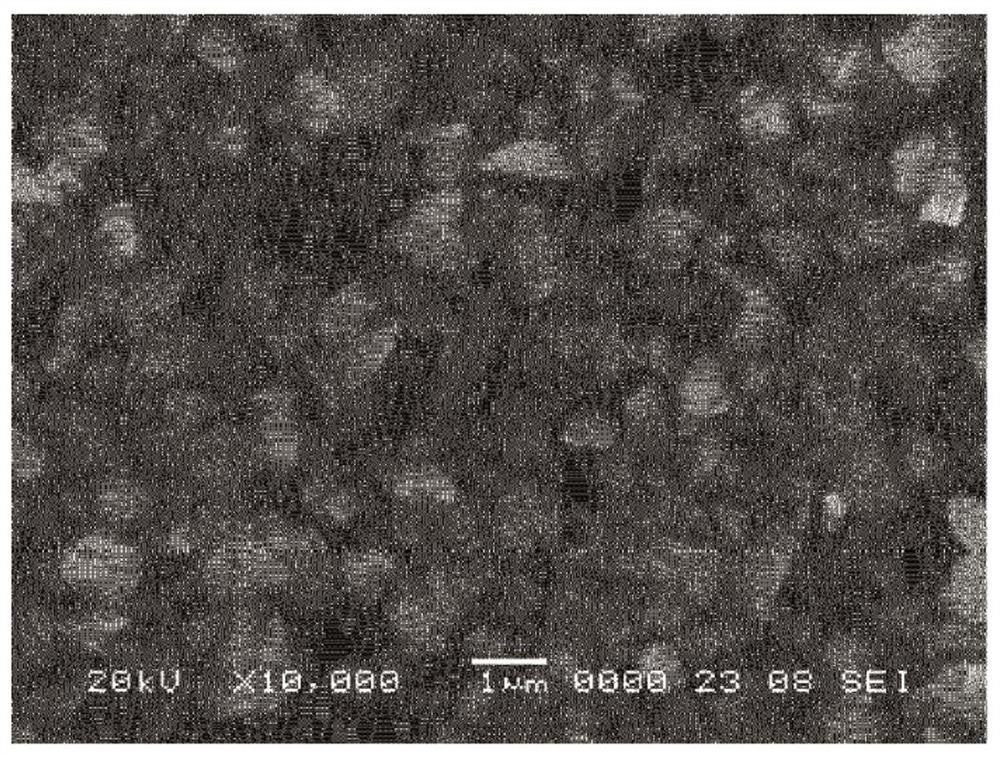

[0205] A bead mill (manufactured by AIMEX Corporation, readymill RMB-08) is used as the intermittent medium agitation type pulverizer. The pulverization container (outer cylinder material: SUS304, inner cylinder material: zirconia, etc., effective volume: 125 mL), put 6.0 g of germanium metal (manufactured by High Purity Chemical Co., Ltd., 45 μm pass, true density 5.3 g / mL, Mohs hardness 6.0, D 90 -D 10 =21.52,D PT =15.89), 108g zirconia beads as beads ( True density 5.7g / mL), isopropanol (manufactured by Fujifilm Wako Pure Chemical Industries, Ltd., true density 0.79g / mL) as the quality 24.0g of dispersion solvent, the zirconia shaft is set, and the rotation stirring beads by the shaft, Metal material 1 is subjected to wet pulverization. When performing wet pulverization, use a cooler set at 10°C to allow water to flow between the outer cylinder and the inner cylinder of the pulverization container, and set the temperature of the pulverization container so that it is suff...

Embodiment 2

[0210] Except that the ratio of the mass of the metal material 1 to the mass of the beads was 0.083, wet pulverization was performed under the same conditions as in Example 1, and the dispersion liquid A2 was collected. When measuring the particle size distribution of dispersion A2, the particle size width D 90 -D 10 1.10μm, peak D PT is 0.89 μm.

Embodiment 3

[0212] The wet pulverization was carried out under the same conditions as in Example 1 except that the peripheral speed was set at 5 m / s, and the dispersion liquid A3 was recovered. The particle size distribution of the dispersion A3 was measured, the particle size width D 90 -D 10 1.50μm, peak D PT is 0.89 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com