High-strength cold-rolled steel sheet having excellent formability and coating properties, zinc-based metal-plated steel sheet made therefrom, and manufacturing method

A cold-rolled steel sheet, formability technology, applied in metal material coating process, coating, hot-dip plating process, etc., can solve the problems of high production cost and difficulty, and achieve improved coating characteristics, excellent formability, enhanced Effect of bake hardening characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

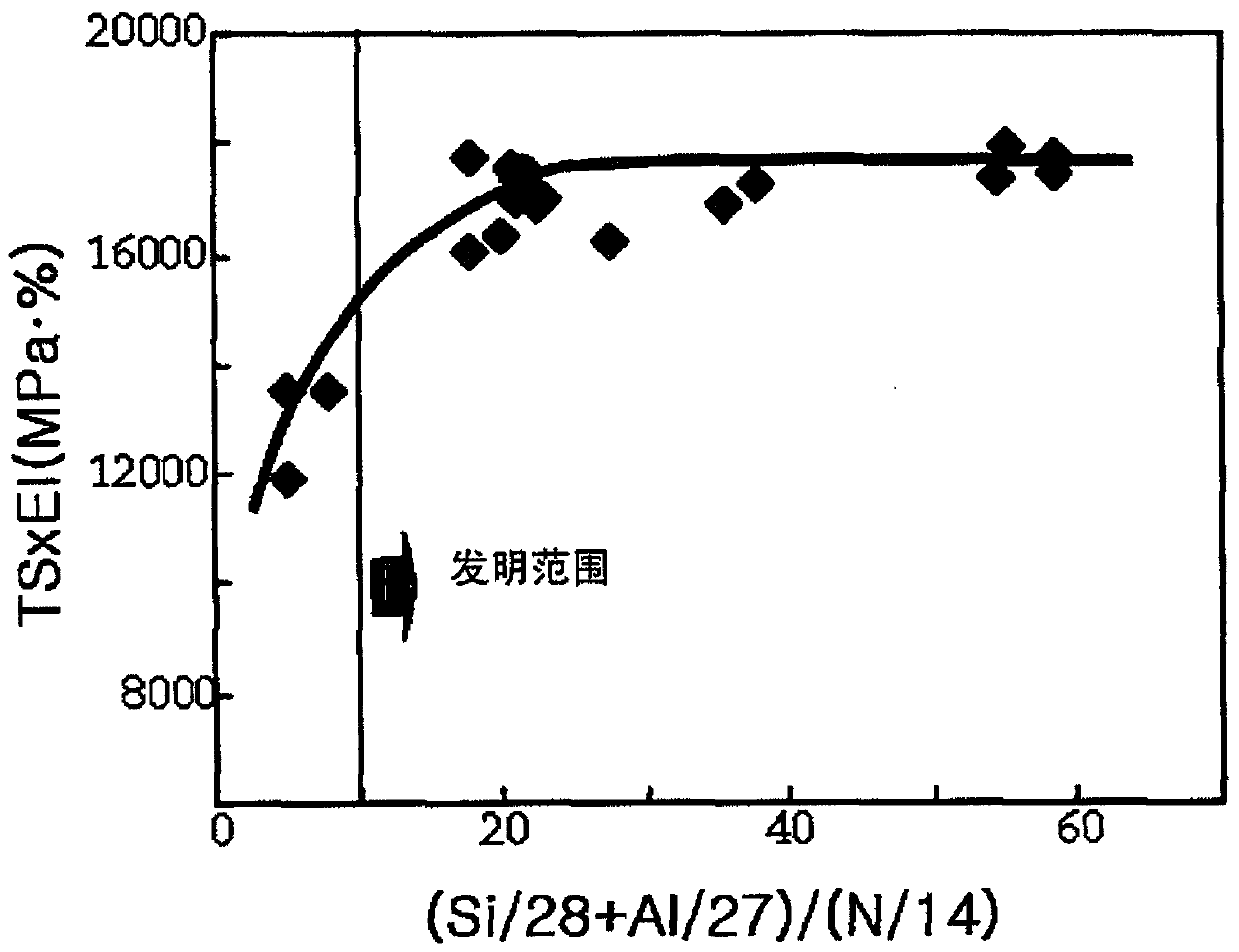

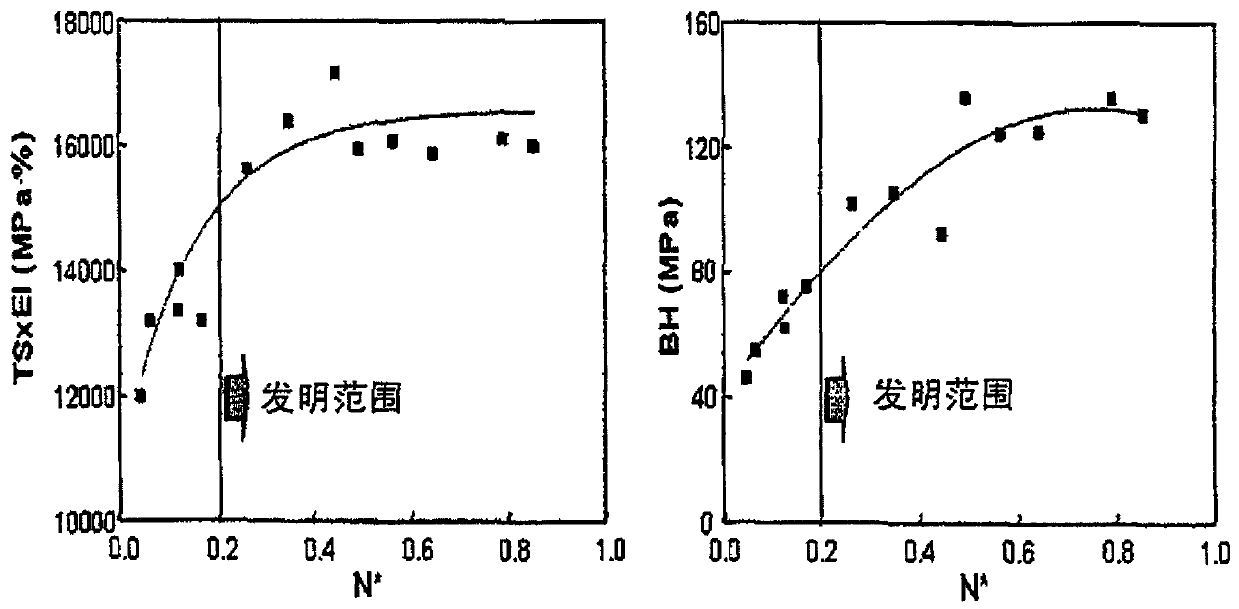

[0038] In addition, when formability needs to be further improved in addition to the above-mentioned coating characteristics, according to one embodiment of the present invention, it is preferable to control the content of nitrogen (N) to satisfy one or both of the following inequalities:

[0039] (Si / 28+Al / 27) / (N / 14)≥10(l)

[0040] N*=(N / 14) / (Al / 27+Ti / 48+Nb / 93+V / 51+B / 11)≥0.2(2)

[0041] Furthermore, in one embodiment of the present invention, the bake hardening characteristics are also improved due to the fixation of dissolved nitrogen after the steel sheet is coated.

[0042] The composition of the steel material according to the present invention will be described below.

[0043] Steel Composition

[0044] Carbon (C): 0.01-0.2%

[0045] Carbon (C) is a very important component for increasing the strength of the steel sheet and securing a composite structure composed of ferrite and martensite. When the carbon content is less than 0.01%, it is impossible to obtain the str...

Embodiment 1

[0107] Thick steel plates having the steel composition shown in Table 1 below were subjected to vacuum melting, heated in a heating furnace at a reheating temperature of 1150° C. to 1250° C. for 1 hour, and then hot rolled and bent. Finish hot rolling at 850°C-950°C. The bending temperature was set at 650°C. Then, the hot-rolled steel sheet is pickled and cold-rolled at a cold-rolling reduction ratio of 50-70%. Under the conditions shown in Table 2, the cold-rolled steel sheets were subjected to continuous annealing, primary cooling and secondary cooling. For the tensile strength test, the JIS5 test strip is taken from the continuously annealed cold-rolled steel plate to check the quality of its material.

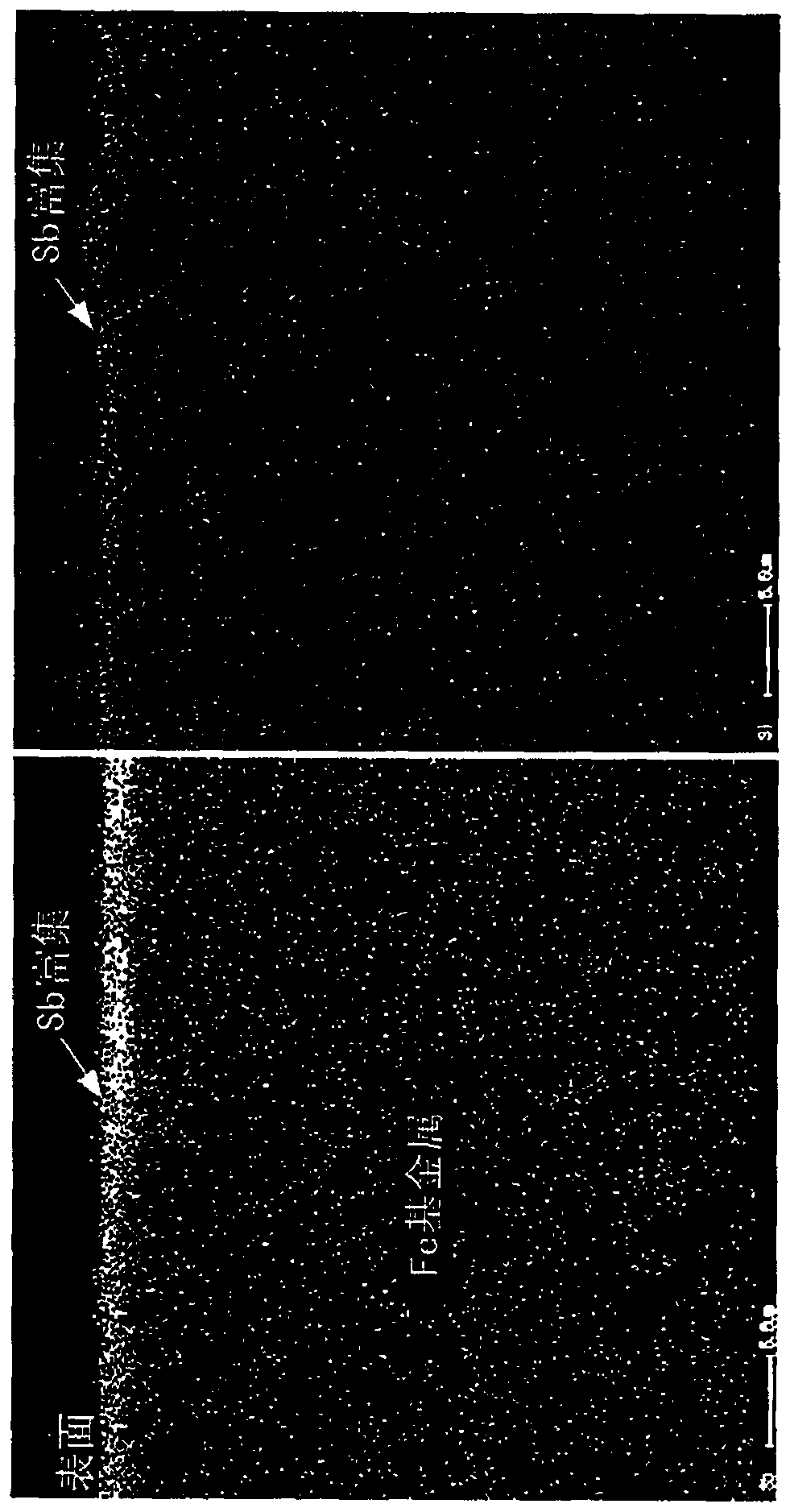

[0108] In addition, in order to observe the coating characteristics, the continuously annealed steel sheet manufactured as described above was heated to 460°C, hot-dip galvanized for 5 seconds, alloyed at 500°C for 10 seconds, then cooled to room temperature, and then obs...

Embodiment 2

[0122] Thick steel plates having the steel composition shown in Table 4 below were subjected to vacuum melting, heated in a heating furnace at a reheating temperature of 1150° C. to 1250° C. for 1 hour, and then hot rolled and bent. Hot rolling is terminated at 850°C-950°C. The bending temperature was set at 650°C. Then, the hot-rolled steel sheet is pickled and cold-rolled at a cold-rolling reduction ratio of 50-70%. The cold-rolled steel sheets were subjected to continuous annealing, primary cooling and secondary cooling under the conditions shown in Table 5.

[0123]For the tensile strength test, the JIS5 test strips were taken from the annealed cold-rolled steel sheets and inspected for their material quality. In addition, in order to simulate the quality of the material after being coated on an automobile part, a 2% strain (strain) was added to the JIS5 test strip prepared as described above, and then the test strip was boiled in oil at 170° C. for 20 minutes, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com