Electrical steel sheet with insulating coating

A technology of electromagnetic steel sheet and insulating film, which is applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., to achieve the effect of excellent film characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] (1) Raw materials

[0054] An electrical steel sheet [A230 (JIS C2552 (2000))] having a plate thickness of 0.5 mm was used as a test material.

[0055] (2) Surface treatment agent

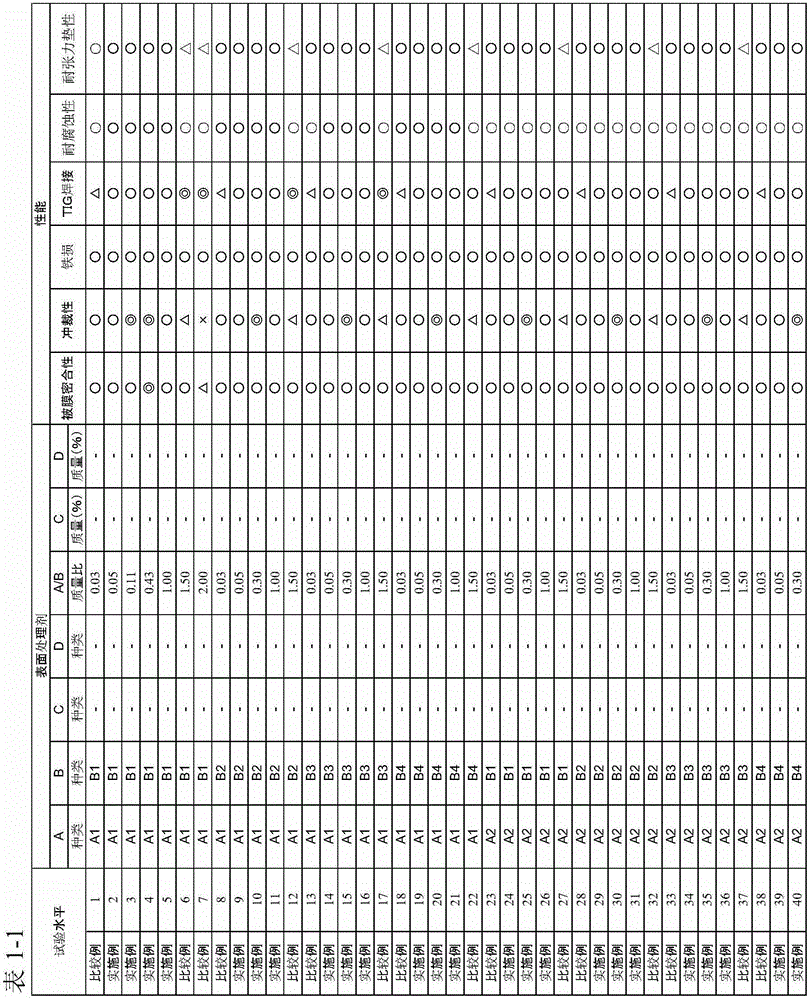

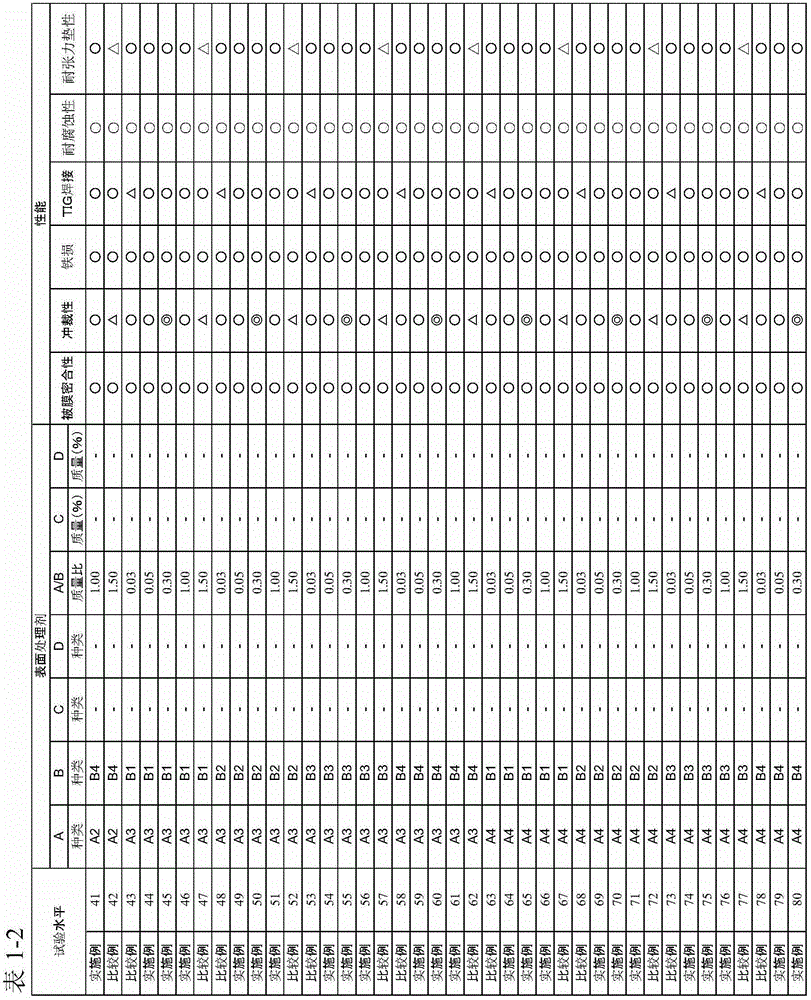

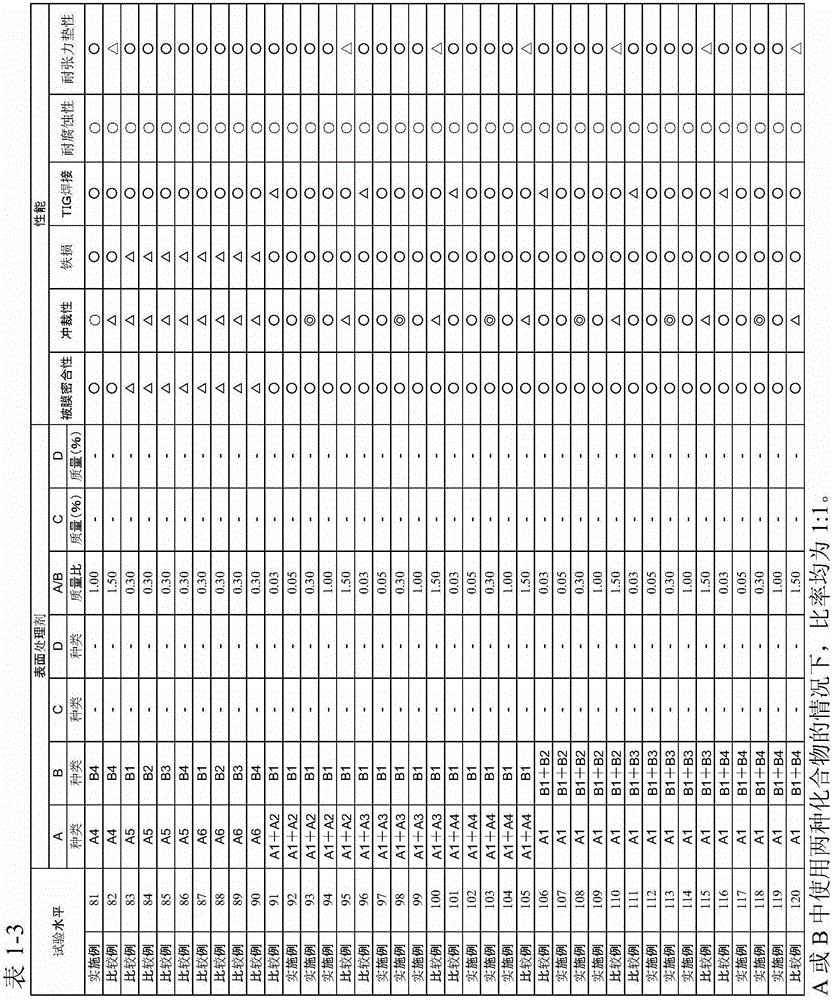

[0056] Each component was mixed in water with the composition (mass ratio) shown in Table 1, and the surface treatment agent was obtained.

[0057] (3) Processing method

[0058] After annealing in a continuous annealing line to obtain a specified material, a surface treatment agent is applied by a roll coater after the steel plate is cooled, and dried using an oven at a maximum plate temperature of 140°C. The film adhesion on both sides is 600mg / m 2insulating film. As the conditions of the roll coater, three rolls and a full reverse system were set. In addition, drying temperature means the arrival temperature of the test board surface.

[0059] Next, the compounds used in Table 1 will be described.

[0060]

[0061] A1: Methyltrimethoxysilane

[0062] A2: Methyltriethoxysilane

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com