Composition for hard mask

A kind of hard mask and composition technology, applied in the field of hard mask composition, can solve the problem of insufficient etching resistance characteristics and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

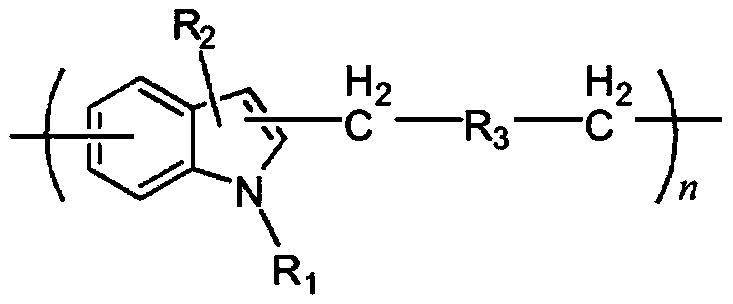

Method used

Image

Examples

Synthetic example 1

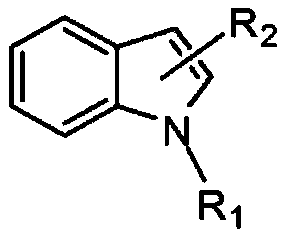

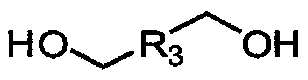

[0118] Synthesis Example 1 (Polymer A-1)

[0119] A 1L three-neck flask equipped with a thermometer, a condenser, a stirrer, and a dropping funnel is placed in an oil container, and 19.3 g (0.1 mol) of the compound represented by Chemical Formula 2-1 is added to the reactor and dissolved in 200 g of propylene glycol monomethyl Phenyl ether acetate (PGEMA). Thereafter, 0.19 g (0.002 mol) of sulfuric acid was added. A solution obtained by dissolving 13.8 g (0.1 mol) of the compound represented by Chemical Formula 3-1 in 100 g of PGMEA was filled in the dropping funnel, and the solution was added dropwise for 2 hours while maintaining the temperature inside the reactor at 120°C. After the dropwise addition, it was further stirred at the same temperature for 12 hours, then 0.45 g (0.003 mol) of triethanolamine as a neutralizing agent was added to the reactor and stirred at normal temperature for 1 hour, cooled to normal temperature to obtain The reaction mixture was added back d...

Synthetic example 2

[0122] Synthesis Example 2 (Polymer A-2)

[0123] Except having used 18.8 g (0.1 mol) of the compound represented by chemical formula 3-2 as an aryl alcohol derivative, the polymer represented by following chemical formula (A-2) was obtained by the method similar to the said synthesis example 1. The above polymer had a weight average molecular weight (Mw) of 1730 and a degree of dispersion (Mw / Mn) of 1.2.

[0124] [Chemical formula A-2]

[0125]

Synthetic example 3

[0126] Synthesis Example 3 (Polymer A-3)

[0127] The polymer represented by the following chemical formula (A-3) was obtained by the method similar to the said synthesis example 1 except having used 26.2 g (0.1 mol) of the compound represented by chemical formula 3-3 as an aryl alcohol derivative. The above polymer had a weight average molecular weight (Mw) of 1780 and a degree of dispersion (Mw / Mn) of 1.5.

[0128] [Chemical formula A-3]

[0129]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dispersion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com