Tin plating solution, preparation method and application thereof

A technology of tin plating solution and tin methanesulfonate, applied in semiconductor devices, circuits, etc., can solve the problems of small gaps, uniform thickness of solder bumps, etc., and achieve the effects of reducing height fluctuations, improving current efficiency, and excellent coating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

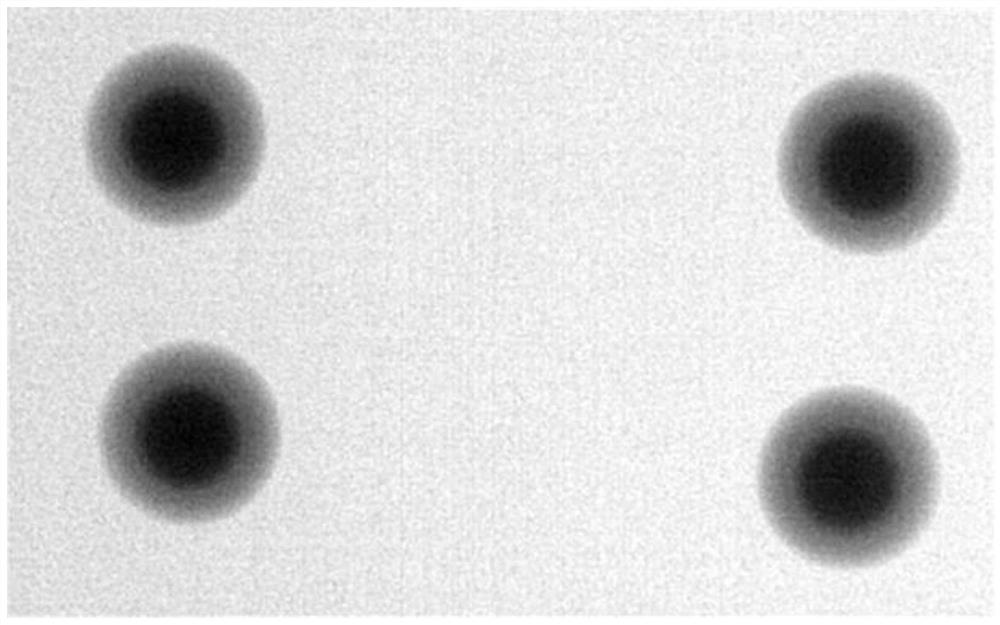

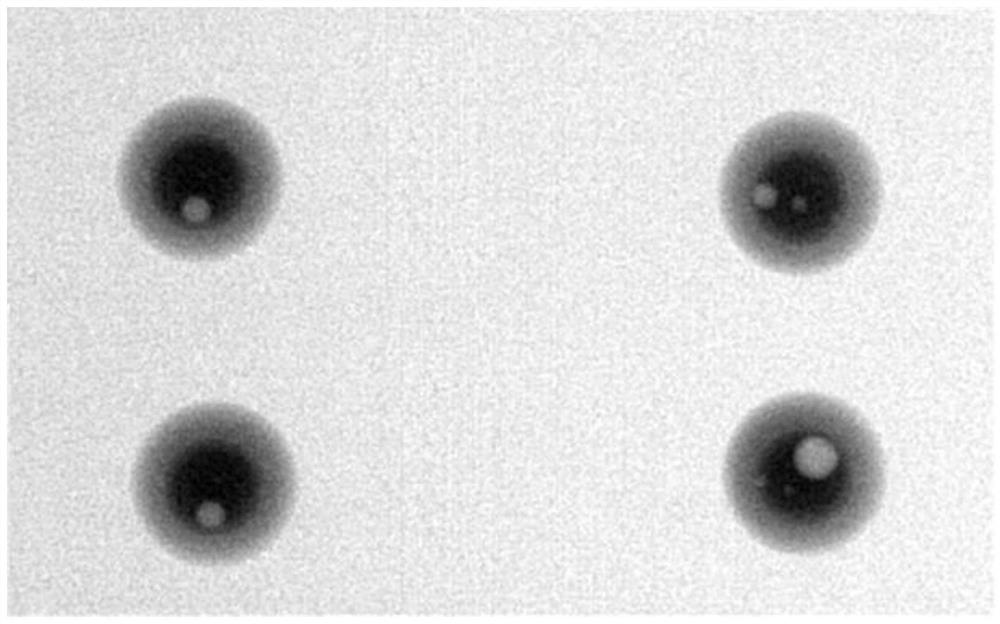

Image

Examples

Embodiment Construction

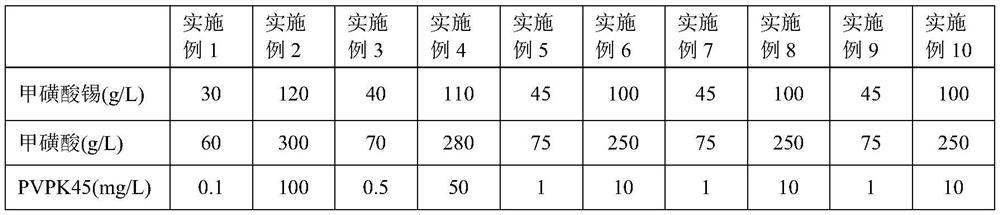

[0031] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples. For the experimental methods that do not specify specific conditions in the following examples, select according to conventional methods and conditions, or according to the product instructions.

[0032] 1. Formation of copper pillars

[0033] Copper pillars are formed on the copper UBM layer of the flip chip semiconductor package. Specifically, with CuSO containing 4 ·5H 2 O, H 2 SO 4 , HCl, H 2 A commercially available copper sulfate-based plating solution of O and additives (SYS2310, Shanghai Xinyang Semiconductor Co., Ltd., China) was stirred at room temperature and heated at 10 A / dm 2 A 12-inch patterned wafer was electroplated at a current density of 12 inches to form copper pillars until the height of the copper pillars reached 10 μm; copper electroplating was performed according to the manufacturer's recommendation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com