Spiral oil pipe paraffin removal device

A helical, tubing technology, used in cleaning appliances, wellbore/well components, earth-moving drilling, etc., can solve the problems of poor timeliness, high cost, high energy consumption, etc., and achieve low cost, easy operation, and easy installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

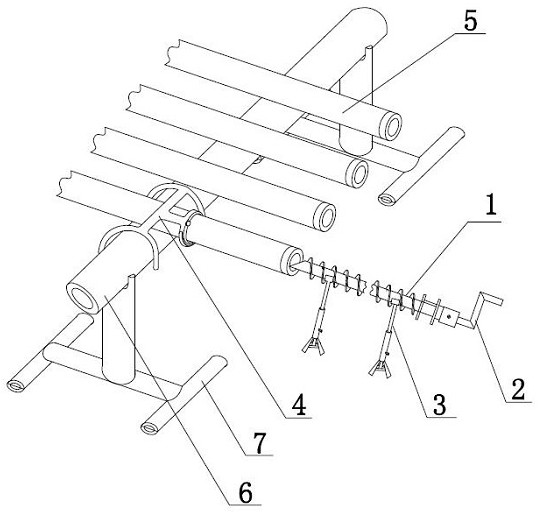

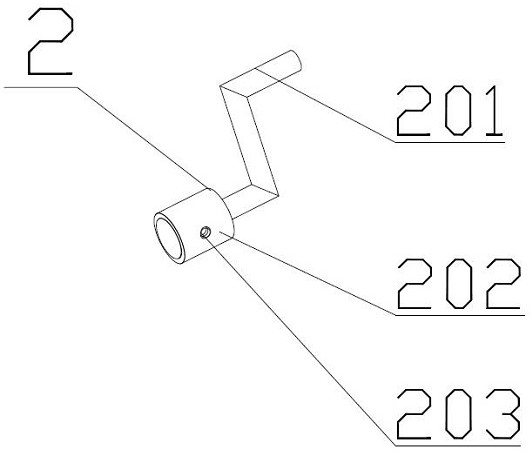

[0022] The oil pipe with an inner diameter of 62 mm has an oil rod with a diameter of 22 mm inside the pipe. When the wax deposition is serious, the thickness of the pipe wall reaches 20 mm. Figure 1-5 As shown, the spiral oil pipe wax removal device adopted in the present invention includes a wax scraper 1, a rocker 2, a support 3, a pipe gripper 4, a pipe bridge frame 6 and a pipe bridge stool 7, and the pipe bridge frame 6 is supported by the pipe bridge stool 7 , place the oil pipe 5 on the pipe bridge 6, fix the oil pipe 5 that needs wax removal with the pipe gripper 4, and set two downward U-shaped pipe clips 404 on the pipe gripper 4, use the pin shaft 403 and the clamp 401 is connected and fixed in one body, and the caliber of the U-shaped pipe clip 404 is smaller than that of the pipe bridge. Utilize the tension of the U-shaped pipe clip 404 to firmly fix the oil pipe 5 to be waxed on the pipe bridge frame 6, and then use the tight The hoop 401 locks the oil pipe 5 s...

Embodiment 2

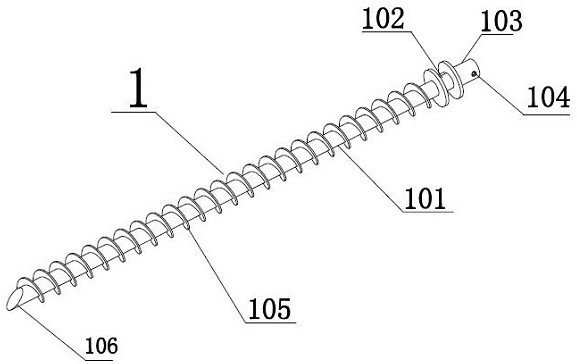

[0028] The difference from Example 1 is that under normal circumstances, the length of the oil pipe 5 is different, and a longer wax scraper (1) is required, but the wax scraper 1 is too long and inconvenient to carry, so the wax scraper 1 can be made into Assemblies connected by multi-section detachable wax scraper nipple 1A, as attached figure 1 with 6 As shown, the sharpened part 106 of the wax scraper 1 is set on the short joint at the front end, and the short joint at the tail end is provided with a butt joint 103, which is fixedly connected with the crank handle 2, and one end of the short joint 1A of the wax scraper connected in the middle is provided with an outer Thread, the other end is provided with an internal thread, the other end of the wax scraper pup 1A with a sharpened portion 106 is provided with an internal thread, and the other end of the wax scraper pup 1A with a butt joint 103 is provided with an internal thread, detachable The wax scraper nipple 1A is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com