Unattended textile fabric deburring device

A technology for textile fabrics and deburring, used in textiles and papermaking, singeing, thin material processing, etc., can solve the problems of inability to automatically replace discharge rollers and winding rollers, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

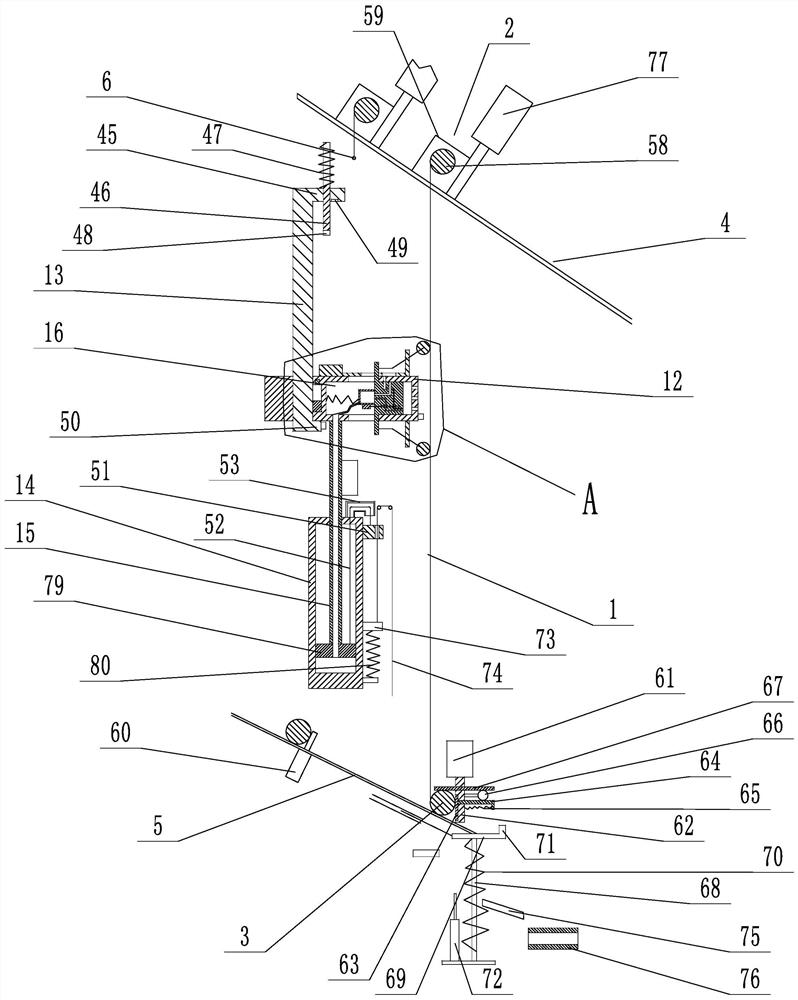

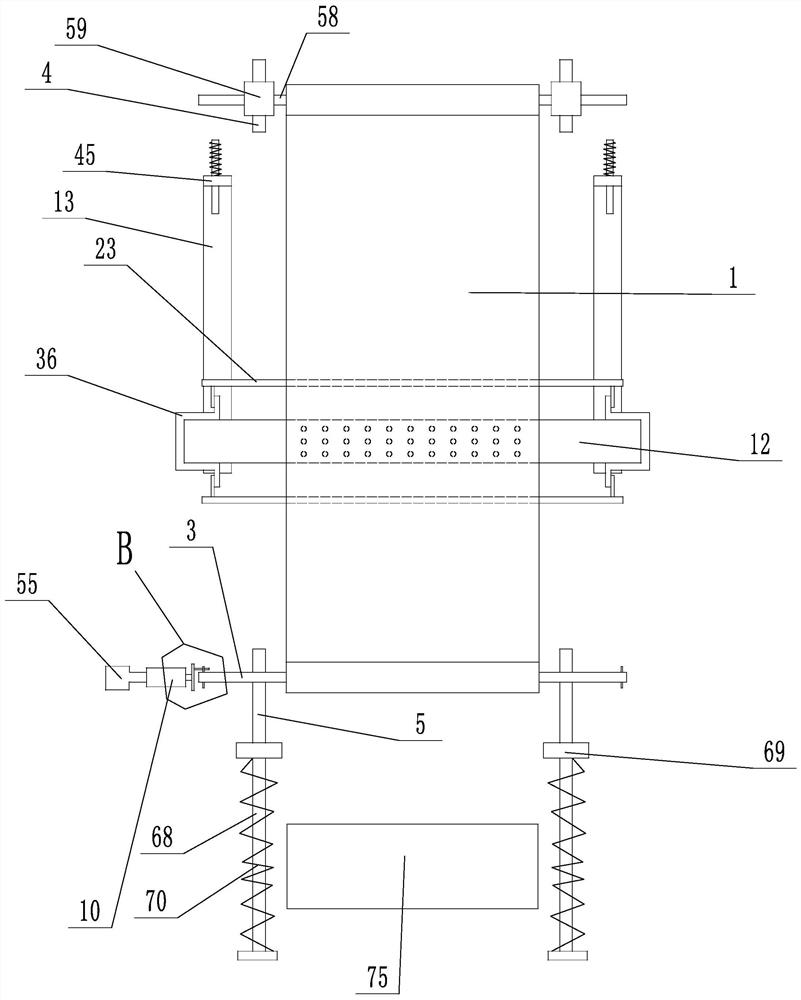

[0033] see Figure 1 to Figure 16 , an unattended textile cloth deburring device, comprising several discharge rollers 2 wound with textile cloth 1, several winding rollers 3 located below the discharge roller 2 for winding textile cloth 1, supported on The upper rail 4 at both ends of the discharge roller 2, the lower rail 5 supported at both ends of the winding roller 3, and the fire injection mechanism for burning the burrs on the textile cloth 1 between the upper rail 4 and the lower rail 5;

[0034] The textile cloth 1 on one of the discharge rollers 2 is connected to one of the take-up rollers 3 after passing through the flame-spraying mechanism, and the end of the textile cloth 1 away from the discharge roller 2 is provided with a connecting rod 6;

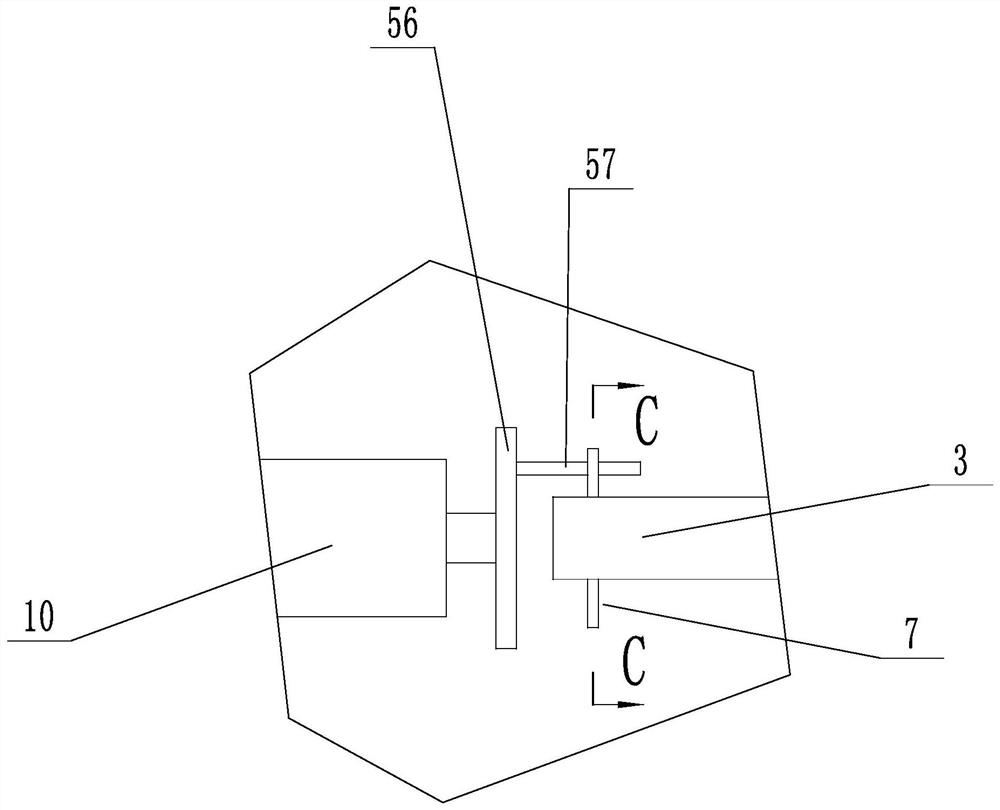

[0035] Both ends of the winding roller 3 are provided with a plurality of claws 7 for cooperating with the connecting rod 6, and the claws 7 are arranged in an annular array around the axis of the winding roller 3;

[0036...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com