Zipper, garment and container

A technology of zipper and zipper teeth, which is applied in the fields of clothing, storage parts and zippers, can solve problems such as danger, and achieve the effect of safety guarantee and good concealment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

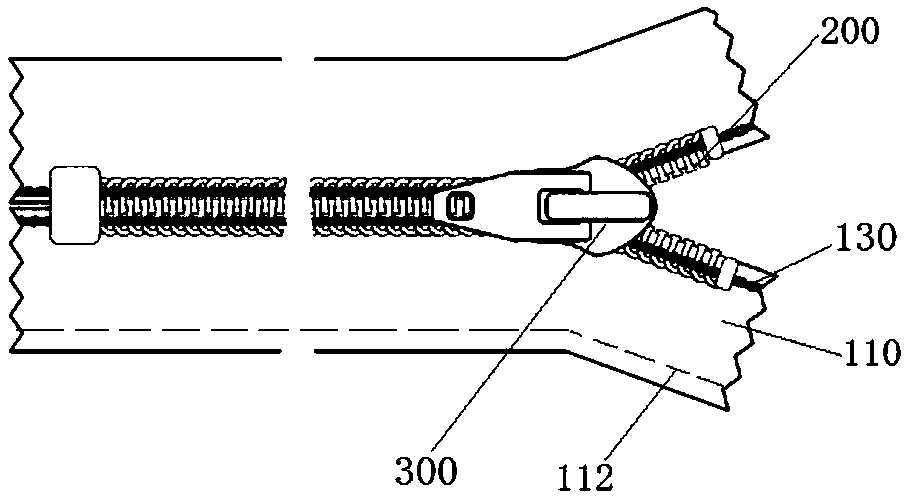

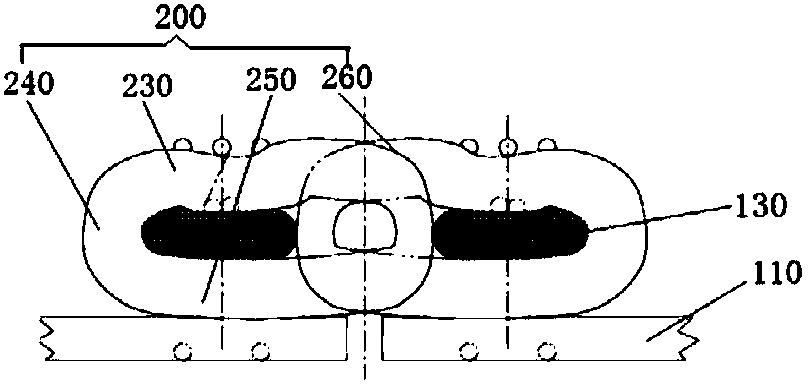

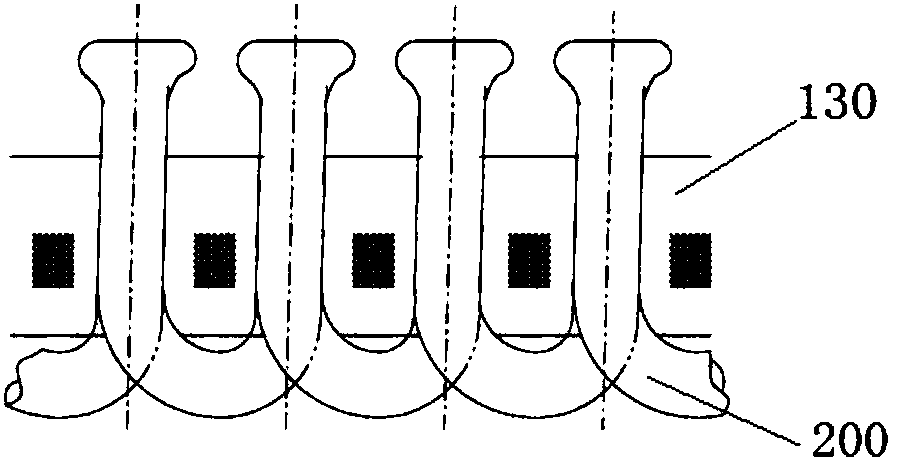

[0064] like Figure 1 to Figure 5 As shown, the zipper of this embodiment includes: a pair of cloth tape bodies 110, zipper teeth 200 and zipper pullers 300 arranged on each cloth tape body 110; the zipper is a coil zipper, and the zipper teeth 200 include multiple The coil elements connected sequentially along the length direction of the belt body 110, each coil element includes an upper leg portion 230, a middle connecting portion 240, a lower leg portion 250 and an articulation portion 260 connected in sequence, the upper leg portion 230, the middle connecting portion 240 , The lower leg portion 250 and the occlusal portion 260 form an inner cavity for a core rope portion 130 to pass through, the upper leg portion 230 and the cloth belt body 110 are connected to the core rope portion 130, and the lower leg portion 250 is connected to the cloth belt body 110; On each tape body 110, at least one of the sewing threads 111 in the length direction of the tape body 110 is an anti...

Embodiment 2

[0075] like Figure 6 to Figure 11 As shown, the difference between this embodiment and Embodiment 1 is that the zipper of this embodiment includes: a pair of tape bodies 110, zipper teeth 200 and zipper pullers 300; one side of each tape body 110 in the width direction The core 120 is installed on the edge, and the core 120 is arranged along the length direction of the tape body 110, and the zipper teeth 200 are connected with the corresponding core 120; on each tape body 110, in the length direction of the tape body 110 At least one of the sewing threads 111 is an antistatic sewing thread 112 or at least one of the sewing threads 121 in the length direction of the core 120 is an antistatic sewing thread 112 .

[0076] The length of the sewing thread in the length direction of the tape body 110 is equal to the length of the tape body 110, and the length of the sewing thread in the length direction of the core 120 is equal to the length of the core 120. Therefore, in the tape ...

Embodiment 3

[0081] like Figure 12 to Figure 16 As shown, the difference between this embodiment and Embodiment 2 is that the zipper element 200 includes a plurality of resin element parts made of resin material, and each resin element part includes a connected resin head 270 and a resin body part 280 , the resin body part 280 is installed on the side of the core part 120 away from the tape body 110 . Since the conductivity of the resin material is weak, the structure of the present invention can ensure that the resin slide fastener has a discharge function in the length direction.

[0082] In this embodiment, the resin heads 270 on the two tape bodies 110 are used for engaging; in each resin fastener element, a resin neck 290 is provided between the resin heads 270 and the resin body 280 . Each resin body part 280 includes an upper body part 281 and a lower body part 282 between which a hole part 283 for accommodating the core part 120 is formed.

[0083]When at least one of the sewing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com