Discharge end device of high-energy mill

A discharge end and mill technology, applied in the direction of grain processing, etc., can solve the problems of not having anti-blocking material, adjusting the grinding fineness and discharging medium, not being suitable for large-scale, high ball loading rate and low energy consumption, etc., to achieve high The effect of ball filling rate, adjustment of grinding fineness and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

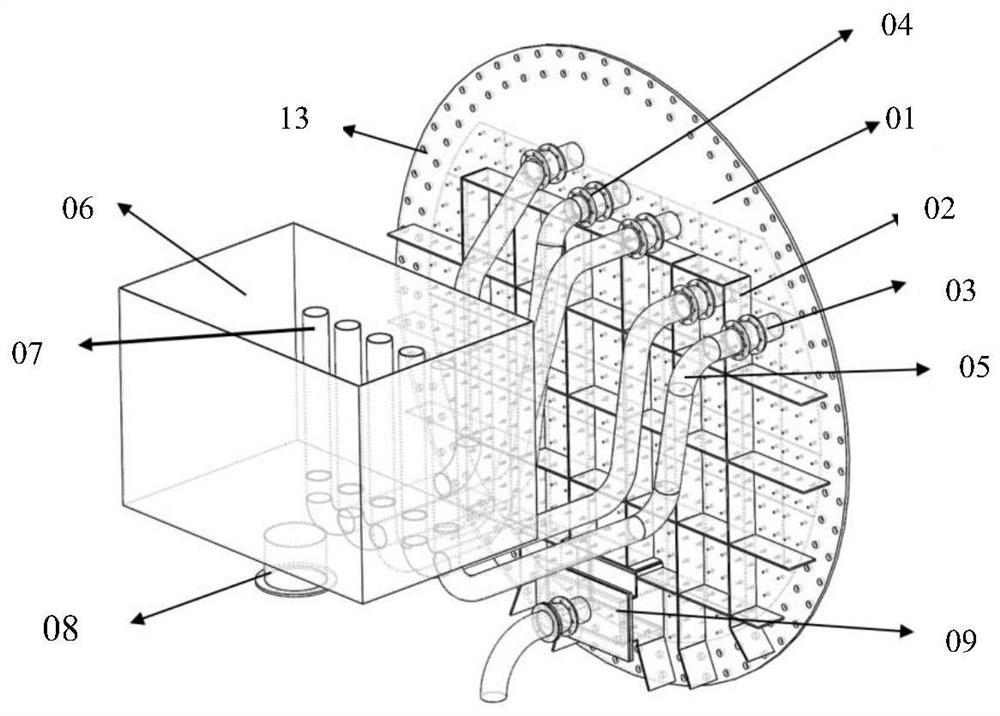

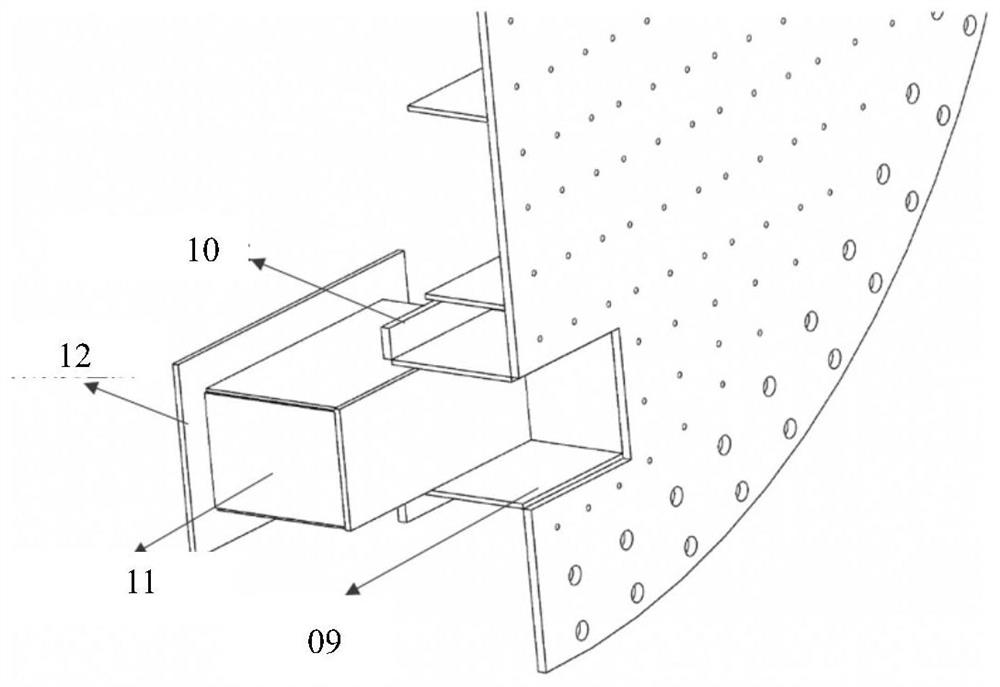

[0023] Embodiment 1, a high-energy mill discharge end device, such as figure 1 As shown, it includes the wet discharge end cover 01 connected with the mill cylinder, the wet discharge end cover 01 is connected with the mill cylinder through the first end cover flange 13, and the wet discharge end cover 01 is provided with Wet discharge module. A plurality of ribs 02 are arranged on the cover surface of the end cover 01 of the wet discharge end, and the ribs 02 include transverse ribs and longitudinal ribs.

[0024] The wet discharge module includes an overflow bin 06 and several overflow ports 03 opened from high to low on the end cover surface of the wet discharge end cover 01; several overflow ports 03 respectively pass through several first branch The road is connected with the overflow material box 06; each first branch road includes the first flexible connection structure 04 and the first diversion pipe 05; several overflow ports 03 are respectively provided with overflo...

Embodiment 2

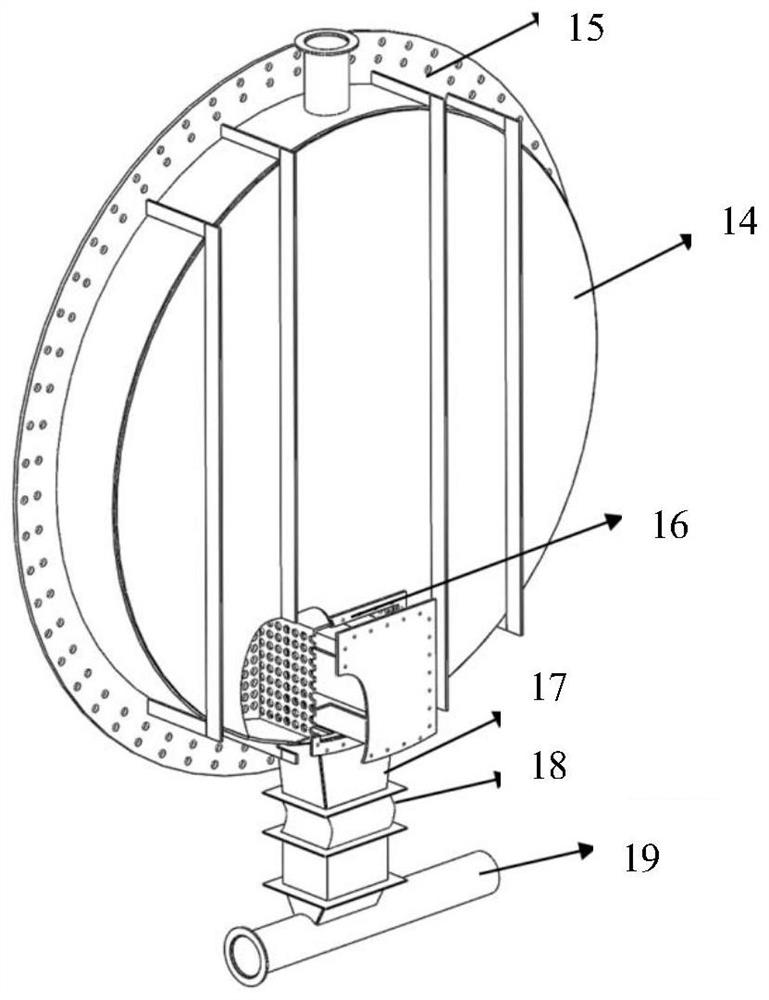

[0027] Embodiment two, a kind of discharge end device of high-energy mill, such as image 3 As shown, it includes a dry discharge end cover 14 connected to the mill cylinder, the dry discharge end cover 14 is connected to the mill cylinder through a second end cover flange 15, and the dry discharge end cover 14 is provided with dry discharge module. The end cover surface of the dry discharge end cover 14 is provided with several longitudinal ribs.

[0028] The dry discharge module includes a dry discharge port 17 and a discharge box; the dry discharge port 17 is connected to the discharge box through a second branch; the second branch includes a second soft connection structure 18 and a second guide The pipe 19 and the dry discharge port 17 are located at the bottom of the dry discharge end cover 14, the dry discharge port 17 is provided with a dry discharge port flange, and the second guide pipe 19 is provided with a second guide pipe Flange, one end of the second flexible ...

Embodiment 3

[0030] Embodiment 3, a high-energy mill discharge end device, including a discharge end cover connected to the mill cylinder, the discharge end cover is connected to the mill cylinder through the end cover flange, and the discharge end cover Equipped with wet discharge module and dry discharge module. A number of transverse ribs and a number of longitudinal ribs are arranged on the end cover surface of the end cover of the discharge end.

[0031]The wet discharge module includes an overflow material box and a number of overflow ports opened from high to low on the end cover surface of the discharge end cover; several overflow ports pass through several first branches and overflow material respectively. Tank connection; each first branch includes a first flexible connection structure and a first diversion pipe; several overflow ports are respectively provided with overflow port flanges; the first diversion pipe is provided with a first diversion pipe flange ; One end of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com