Integrated digital control method based on generalized control mode for electromagnetic bearing

A control method, electromagnetic bearing technology, applied in the direction of bearings, shafts and bearings, program control, etc., can solve the problems of magnetic bearing control systems and digital control systems that have not yet appeared, and achieve the effect of improving the degree of integration and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Below in conjunction with accompanying drawing, the present invention will be further described:

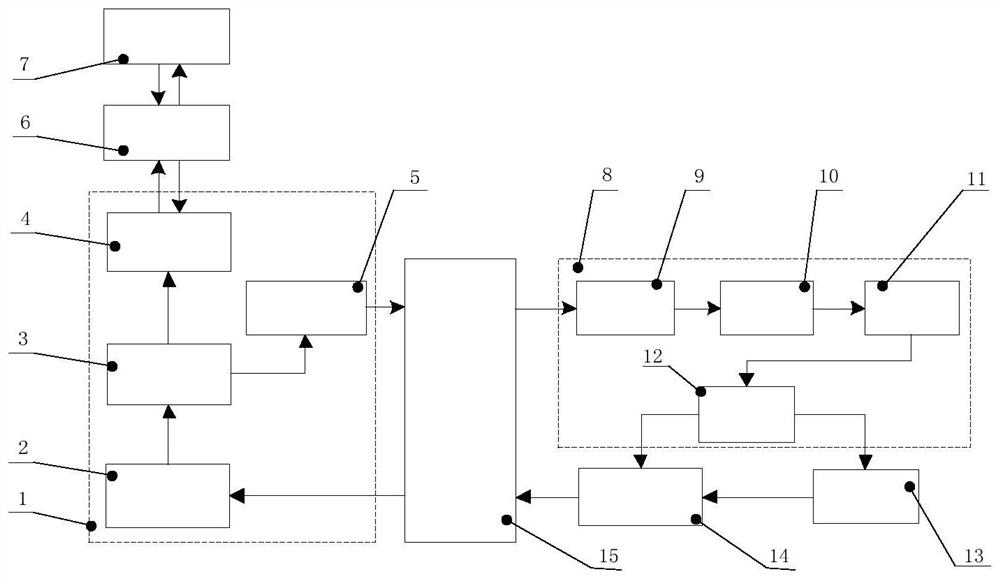

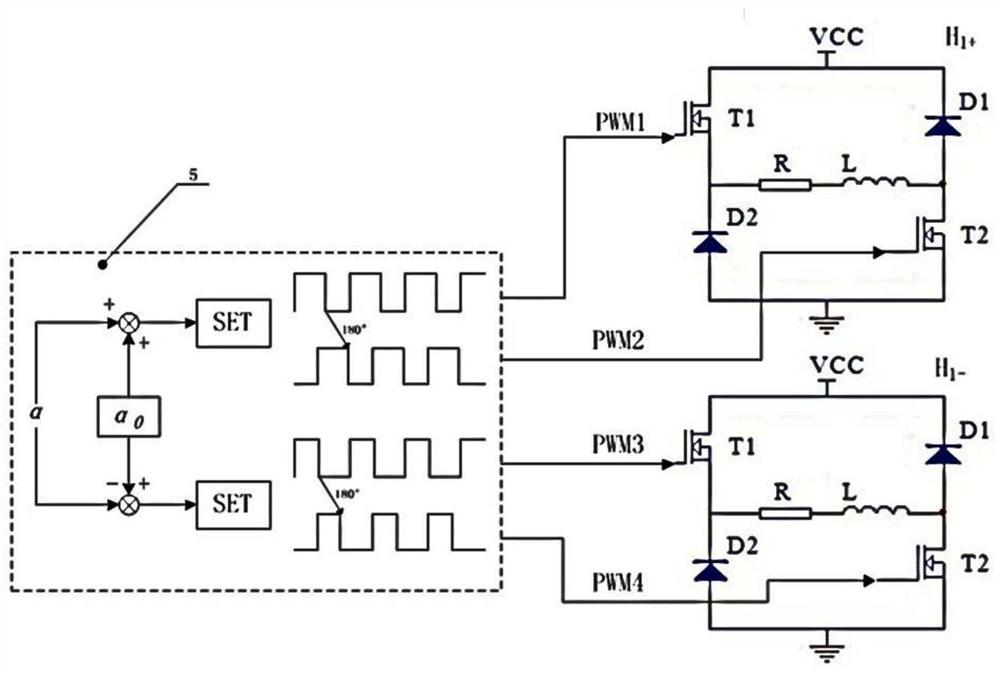

[0056] Such as figure 1 As shown, the present invention comprises DSP core board 1 (comprising A / D module 2, calculation module 3, SPI module 4 and EPWM module 5), Ethernet module 6, computer 7, power conversion board 8 (comprising cache memory module 9, An optocoupler module 10 , a driving module 11 , an H half-bridge transducing circuit 12 ), an actuating device 13 , a signal monitoring module 14 , and a signal conditioning module 15 .

[0057] refer to figure 1 The main chip of the DSP core board is TMS28377D or TMS28379D of TI Company. The main chip of the Ethernet module is W5500. The Ethernet module is inserted on the DSP core board. On the signal conditioning module, the digital and analog grounds on the signal conditioning board are wired separately. The signal conversion board is connected to the power conversion board through a cable. Each power conversion boar...

Embodiment 2

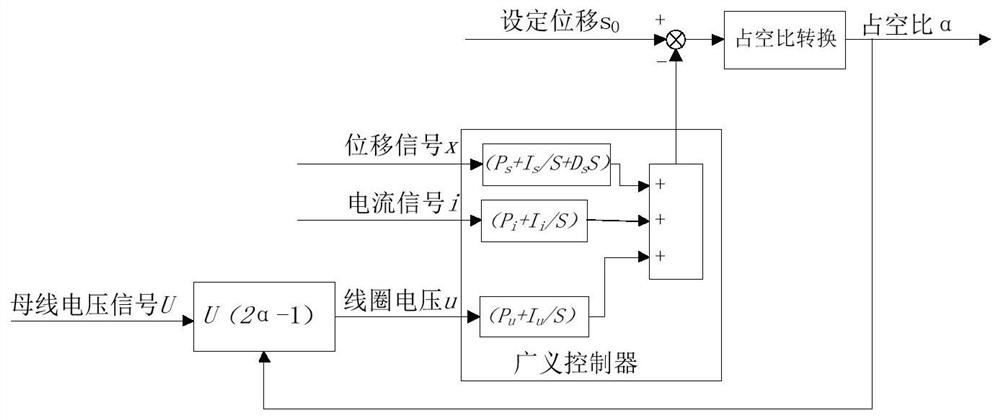

[0061] refer to figure 2 , is the structure of the generalized controller of the present invention. The feedback signal directly measured by the present invention has three items: displacement, current, and bus voltage. The voltage of each coil can be calculated by using the bus voltage and the duty cycle data in the controller. Therefore, there are three effective state feedback parameters available: displacement, current, and voltage. Any control method can be realized by adjusting the values of the seven feedback parameters. Typical construction methods are:

[0062] 1) Current control: set P u and I u set to zero, choose a larger P i and the appropriate I i , close the current loop, simplify the electromagnetic bearing system to a second-order model, and then adjust P s , I s with D s optimization, the current control method can be implemented, and the typical feature of the current method is that it requires a large P i , is completely determined by the hardware...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com