Fluid sample taking and sending closed interface assembly capable of being continuously used

A sample and interface technology, which is applied in the field of fluid sampling and delivery airtight interface components that can be used continuously, can solve the problems of single function, only sending samples, and only sampling, etc., so as to achieve simple operation of taking samples and improving work efficiency , the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

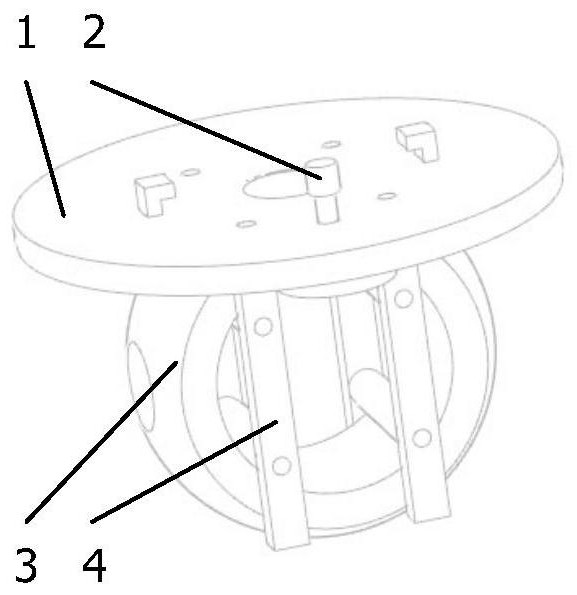

[0034] Example 1: Introduction to component types and functions

[0035] The interface component consists of three parts:

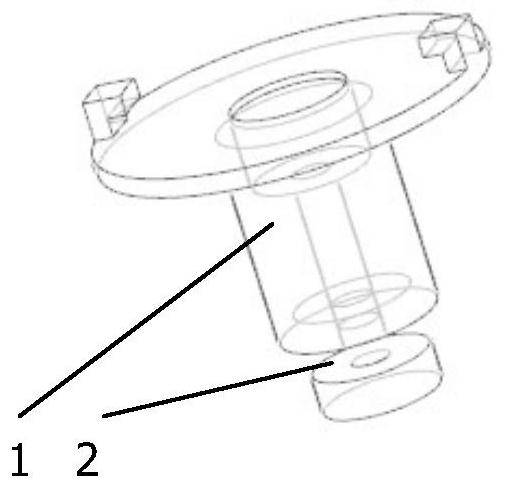

[0036] Container (1): including container shell, container ring switch, container control knob, container fixing frame. Wherein the ring switch of the container is threadedly connected with the control knob of the container.

[0037] Sample (2): including the sample housing, the sample spherical switch, the sample control knob, and the sample concave piston.

[0038] Resetting part (3): including the reset part housing and the convex piston of the reset part.

[0039] When taking and sending samples, the container (1) is joined with the sample (2). It is fixed by a convex key and a card slot, and the ring switch of the container is combined with the spherical switch of the sample. The interface can be seamlessly docked and remains airtight when in use.

[0040] In order to avoid the impact of impurities or residual fluid on the follow-up work, the sa...

example 2

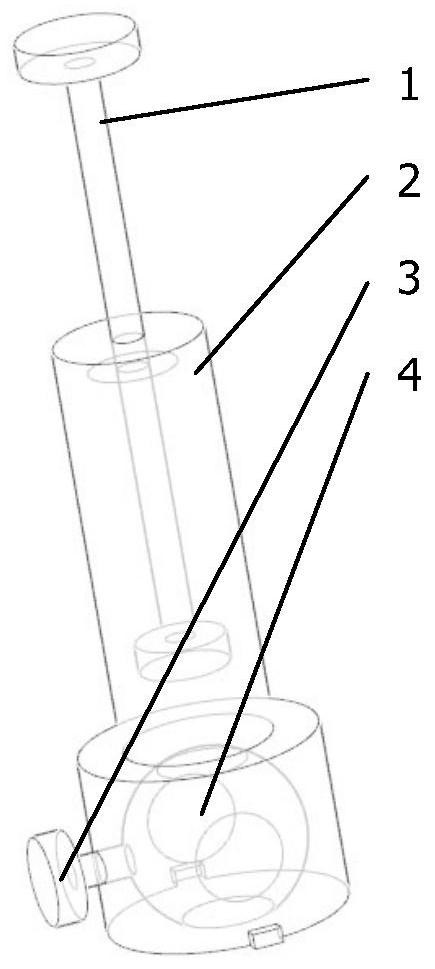

[0043] Example 2: Sampling Operation

[0044] 1. Adjust the posture, turn the ring switch of the container to off, turn the spherical switch of the sample to on, and push the concave piston of the sample to the bottom. (Such as Figure 6 1) of

[0045] 2. Connect and fix the interface between the container (1) and the sample (2). (Such as Figure 6 2) of

[0046] 3. Turn the ring switch of the container to open. (Such as Figure 6 of 3)

[0047] 4. Pull up the concave piston of the sample and take a sample. (Such as Figure 6 of 4)

[0048] 5. Adjust the sample ball switch to the concave type to close. (Such as Figure 6 of 5)

[0049] 6. Turn the ring switch of the container to off. (Such as Figure 6 6 of

[0050] 7. Separate interface. (Such as Figure 6 of 7)

example 3

[0051] Example 3: Sample delivery operation

[0052] 1. Adjust the posture, turn the ring switch of the container to off, and turn the spherical switch of the sample to the concave shape to close. (Such as Figure 6 of 7)

[0053] 2. Connect and fix the interface between the container (1) and the sample (2). (Such as Figure 6 6 of

[0054] 3. Turn the ring switch of the container to open. (Such as Figure 6 of 5)

[0055] 4. Turn the sample ball switch to ON. (Such as Figure 6 of 4)

[0056] 5. Press the concave piston of the sample to send the sample. (Such as Figure 6 of 3)

[0057] 6. Turn the ring switch of the container to off. (Such as Figure 6 2) of

[0058] 7. Separate interface. (Such as Figure 6 1) of

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com