A type selection method of servo motor for ball screw feed system

A servo motor and ball screw technology, which is applied in the field of servo motor selection, can solve the problems of increasing the development cost of the ball screw feed system, wasting the performance of the servo motor, and cannot be effectively promoted, and achieves a convenient selection method, good Dynamic performance, the effect of important engineering application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

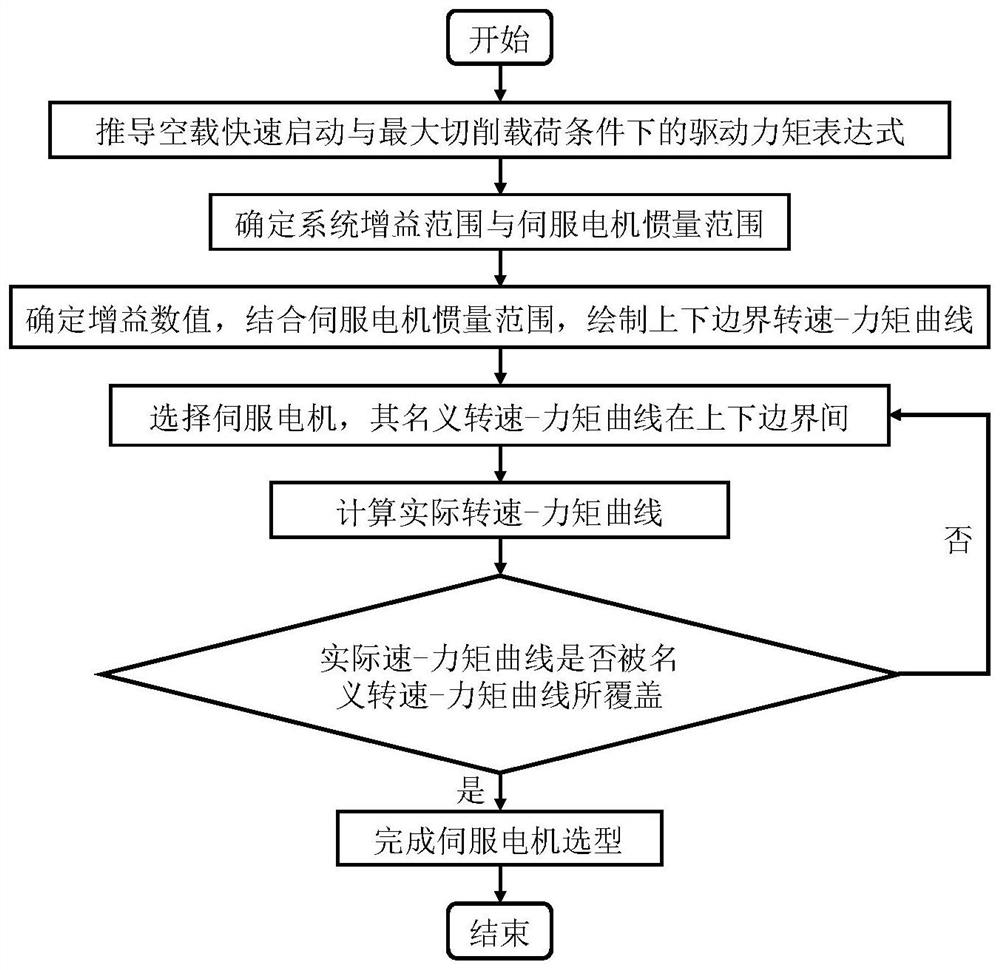

[0026] The servo motor type selection method for the ball screw feed system proposed by the present invention, its flow chart is as follows figure 1 shown, including the following steps:

[0027] (1) Establish the driving torque τ of the servo motor under the condition of no-load quick start A The expression of is as follows:

[0028]

[0029] In the formula, τ A is the driving torque of the servo motor under the condition of no-load quick start, n max is the maximum speed of the servo motor, t a is the acceleration time, J m and J L are servo motor inertia and load inertia respectively, e is the natural base, K s is the gain of the ball screw feed system, η is the mechanical transmission efficiency, the value range of η is 0.85-0.95, τ f is the friction torque, friction torque τ f The value of can be obtained from the parts manual;

[0030] Establish the driving torque τ of the servo motor under the maximum cutting load condition B The expression of is as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com