Half-feeding combine harvester

A combine harvester and half-feeding technology, applied to harvesters, cutters, agricultural machinery and implements, etc., can solve problems such as waste, complex structure, and food loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with specific embodiments.

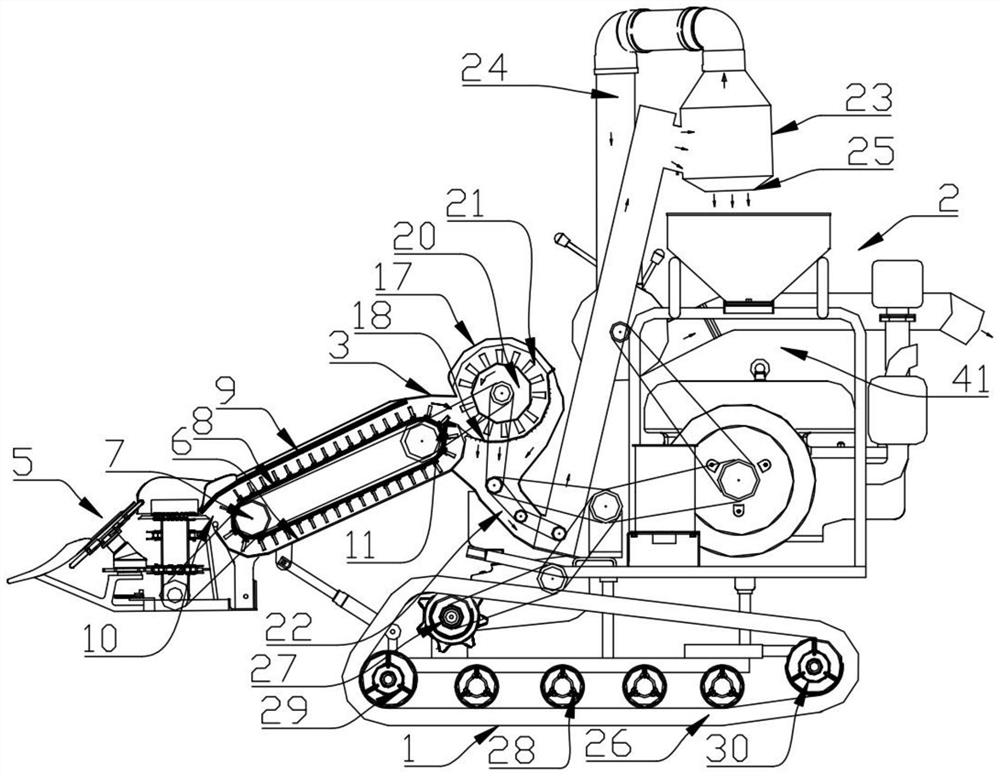

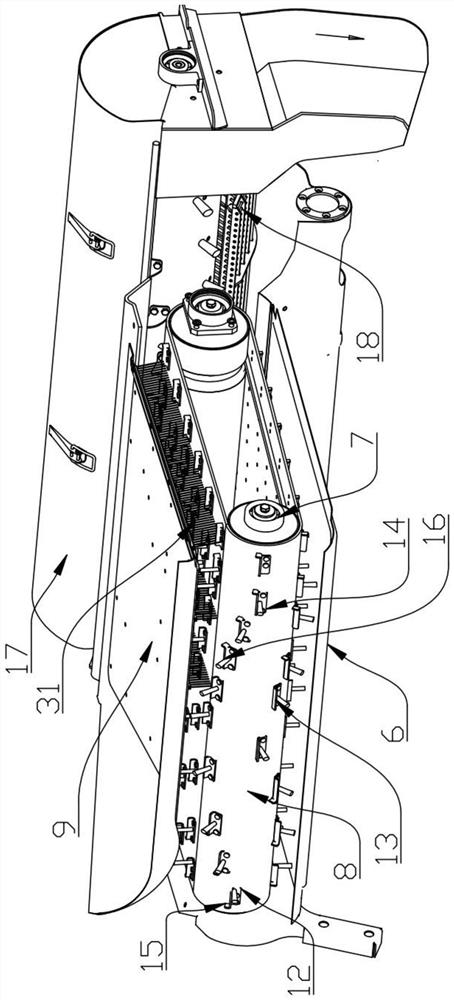

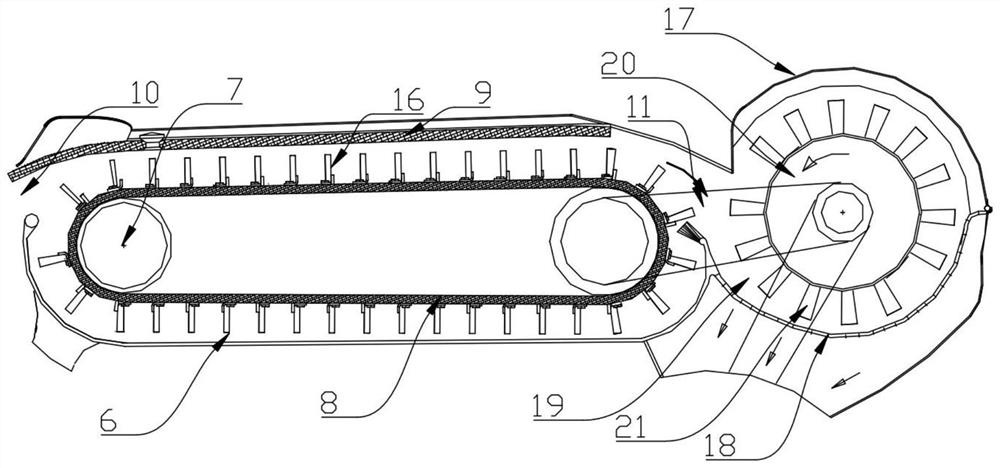

[0028] like Figure 1-4 As shown, a half-feeding combine harvester includes a walking mechanism 1, a grain unloading mechanism 2 arranged on the walking mechanism 1, a threshing mechanism 3 arranged on one side of the grain unloading mechanism 2, and a threshing mechanism 3 arranged on one side of the threshing mechanism 3. Grain cutting mechanism 5; described threshing mechanism 3 comprises housing 6, two rotating drums 7 erected in housing 6 and the threshing conveyer belt 8 installed on the two rotating drums 7, and described housing 6 is provided with There is a first cover plate 9 to prevent the grains from splashing out, and one end of the first cover plate 9 and the housing 6 is formed with a feed port 10, and the other end is formed with a discharge port 11; the threshing conveyor belt 8 is respectively formed There are some first threshing pieces 12 on one side, some second thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com