Pretreatment sterilization device for goose meat processing

A sterilization device and pretreatment technology, applied in the processing of meat, poultry processing and application, can solve the problems of unfavorable sterilization effect of goose meat, waste of water resources, pollution of goose meat, etc., so as to improve the thoroughness of sterilization and avoid Moisture residue and microwave leakage prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

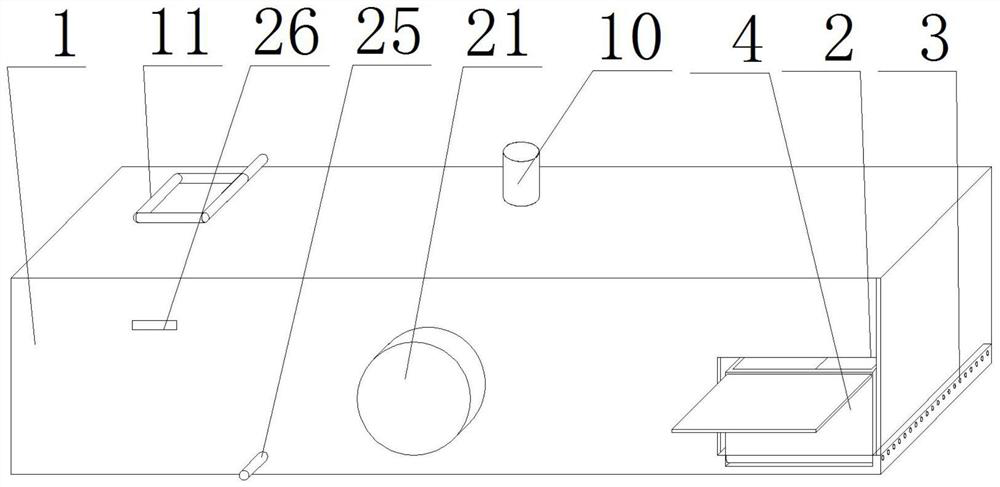

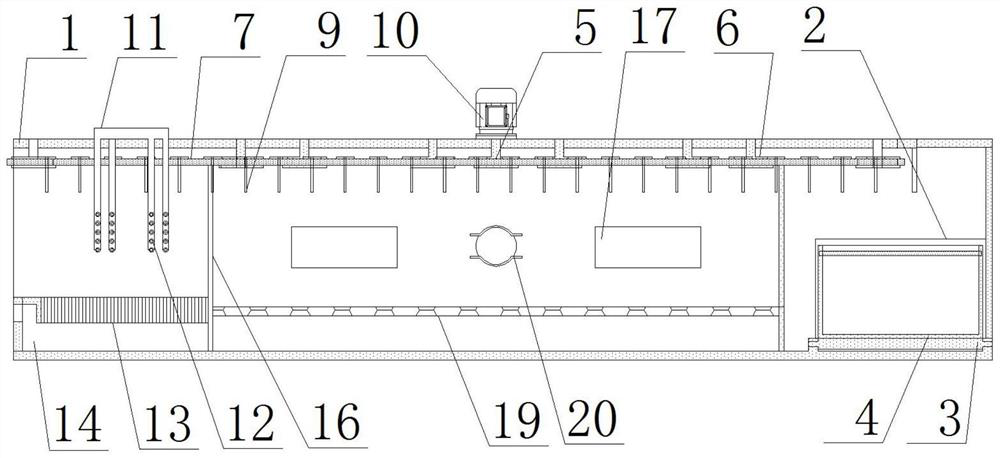

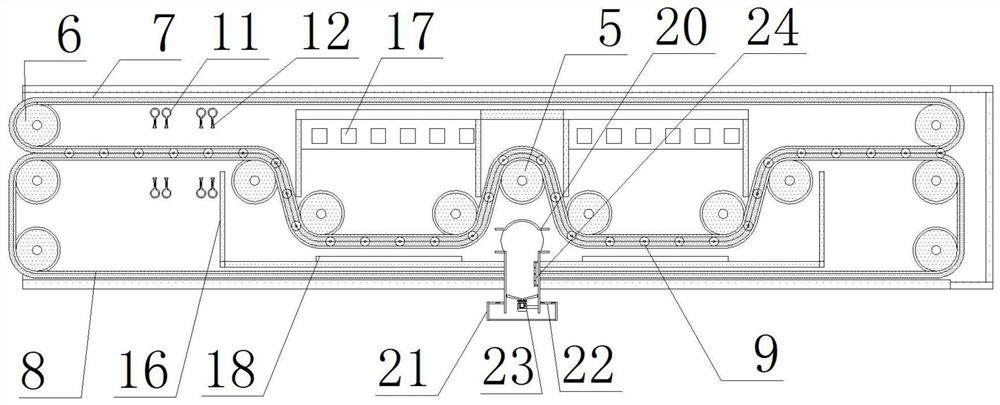

[0028] see figure 1 , figure 2 and image 3 , the present invention provides a technical solution: a pretreatment and sterilization device for goose meat processing, comprising a body 1, an outlet 2, a sliding rod 3 and a box body 4, the outlet 2 is set on the top of one side of the body 1, the The sliding rod 3 is installed on the bottom of the outlet 2 through a rotating shaft, the box body 4 is placed on the top of the sliding rod 3, the top of the body 1 is installed with a main wheel 5 and a runner 6 through a rotating shaft, and the runners 6 are distributed on the main On both sides of the wheel 5, a belt 7 is stuck on the outer sides of the main wheel 5 and the runner 6, a chute 8 is welded on the top of the body 1, a hanging rod 9 is stuck on the belt 7, and the main The top of the wheel 5 is equipped with a motor 10, the top of the body 1 is welded with a trachea 11, the inside of the trachea 11 is welded with a Venturi tube 12, and the Venturi tube 12 is welded w...

Embodiment 2

[0030] See figure 1 , figure 2 and image 3 The difference from Embodiment 1 is that the switch 26 is connected with the motor 10, the microwave generator 17, the fan 23 and the disinfection lamp 24 through electric wires, and the top of the main wheel 5 passes through the top of the body 1 through a rotating shaft and is welded. On the output shaft of the motor 10, the number of the belts 7 is 2, and the belts 7 are all stuck on the inside of the runner 6 and the chute 8, and the two belts 7 are squeezed through the chute 8 and the runner 6. Pressed together, the motor 10 can be turned on through the switch 26, so that the motor 10 drives one of the belts 7 to rotate through the main wheel 5, and the belt 7 drives the other belt 7 to rotate through friction, so that the inner sides of the two belts 7 are in the chute Move from left to right under the limit of 8 and runner 6, the outside of two belts 7 moves from right to left.

Embodiment 3

[0032] See Figure 5 The difference from Embodiment 2 is that the hanging rod 9 includes a top plate, a rotating rod and a shifting plate, the rotating rod is installed at the center of the top plate through a rotating shaft, and the top plate is stuck on the top of the belt 7. The bottom of the rotating rod passes through the gap between the belts 7 and extends to the bottom of the belt 7. The dial is welded on the outer side of the rotating rod, and one side of the dial is stuck on one side of the scraper 18, so that the The meat is fixed on the bottom of the hanging rod 9. When the belt 7 rotates, the top of the hanging rod 9 is stuck between the two belts 7, and the belt 7 drives the hanging rod 9 to move to the inside of the body 1, and when the hanging rod 9 moves When arriving the inboard of dividing plate 16, stir hanging bar 9 by scraper 18, make hanging bar 9 drive goose to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com