Automatic cleaning mopping vehicle with multiple rows of mopping cloth

A technology for automatic cleaning and mopping vehicles, applied in the direction of cleaning carpets, cleaning floors, automatic detection of obstacles, etc., to achieve the effect of reducing the space of the vehicle body, expanding the scope of use, and making turns and U-turns convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

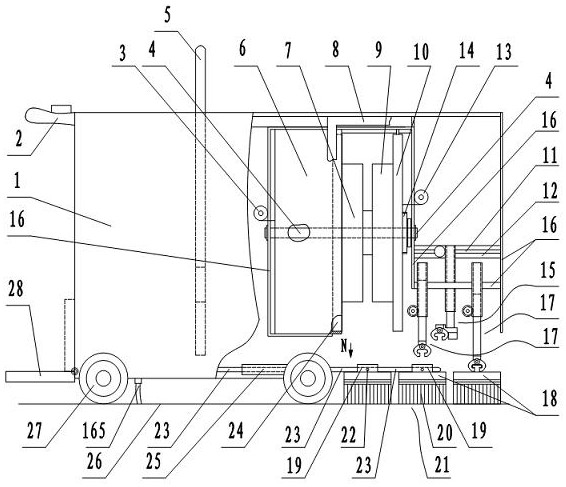

[0024] figure 1 In the middle is the overall structure diagram of the hand-push mopping vehicle. The mopping car includes a variable cleaning pool, a frame device, a wrapping mechanism, a runner, a turning clip device, a side clip device, a guide clip device, a car body, and a mop. Above the front wheels 27 in the vehicle body 1 is the variable washing tank 6 . The variable cleaning tank 6 is hereinafter referred to as the cleaning tank 6 . The cleaning tank is in the shape of a cylindrical shell, and the circular shell is oriented left and right. In the figure, the right side of the cleaning pool is a runner, which consists of a left runner 7 and a right runner 9. The left and right runners are connected in the middle. There is a slot in the middle of the runner. A main shaft 4 passes through the center of the cleaning tank and the center of the runner. Both ends of the main shaft 4 are fixed on the racks 16 on the left and right sides of the cleaning tank. The left ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com