Raw material mixing device for processing Sichuan sausage

A technology of Sichuan-flavored sausage and mixing device, which can be used in mixers, mixers with rotary stirring devices, transportation and packaging, etc., and can solve the problems of inconvenient removal of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

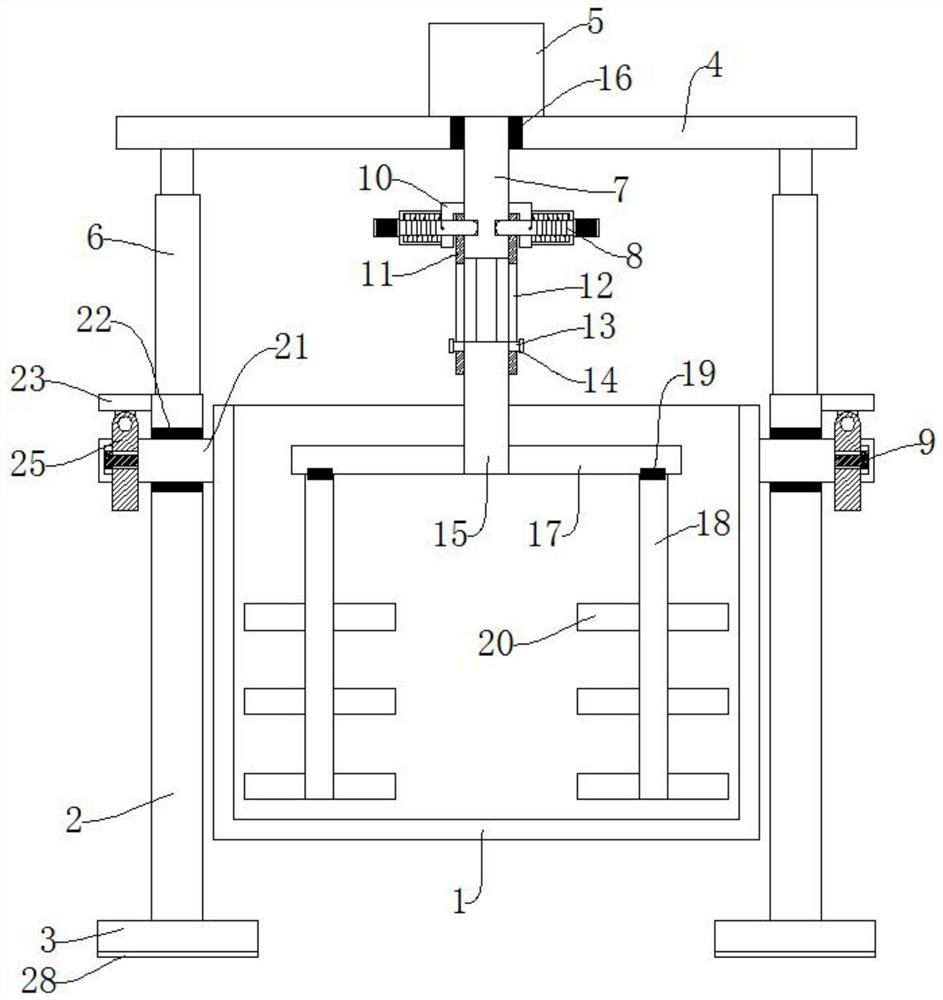

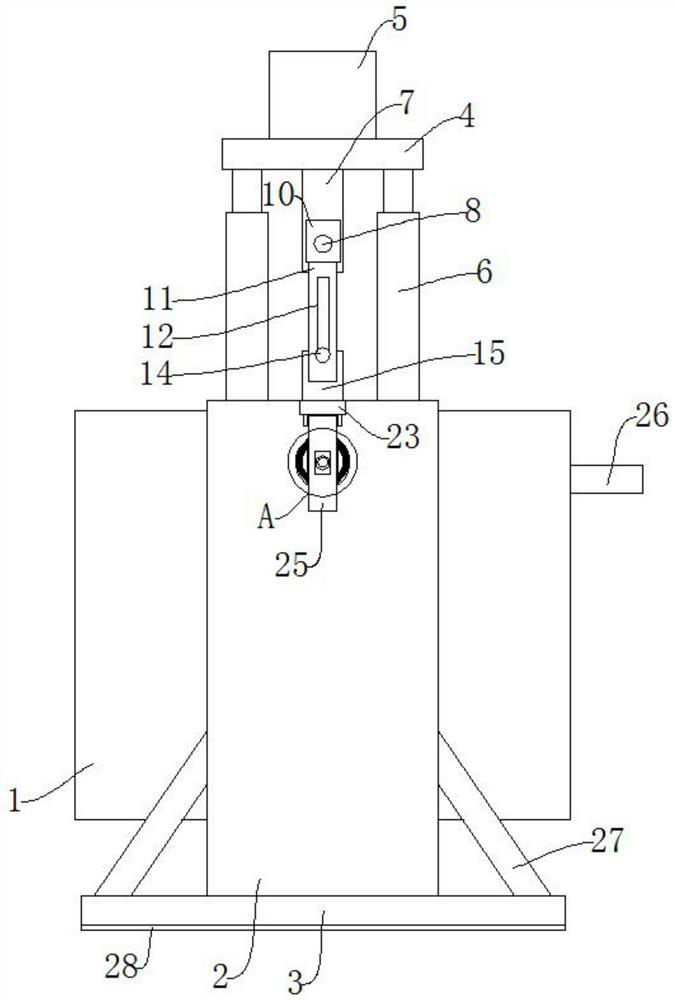

[0022] refer to Figure 1-5 , a raw material mixing device for Sichuan flavor sausage processing, comprising two side plates 2, the two side plates 2 are arranged in parallel, a bottom plate 3 is fixed under the side plates 2, an anti-slip mat 28 is fixed on the bottom of the bottom plate 3, and the side plates 2 One end of the support rod 27 is fixed on both sides below, the other end of the support rod 27 is fixed above the bottom plate 3, a material storage tank 1 is arranged between the two side plates 2, and a handle 26 is fixed on the upper side of the material storage tank 1. Both sides above the bucket 1 are fixed with a side turning rod 21, one end of the side turning rod 21 passes through the side plate 2 and extends outwards, a side bearing 22 is fixed at the contact between the side turning rod 21 and the side plate 2, and one end of the side turning rod 21 is connected to the side plate 2. A side limit mechanism is arranged between the side plates 2, and a support...

Embodiment 2

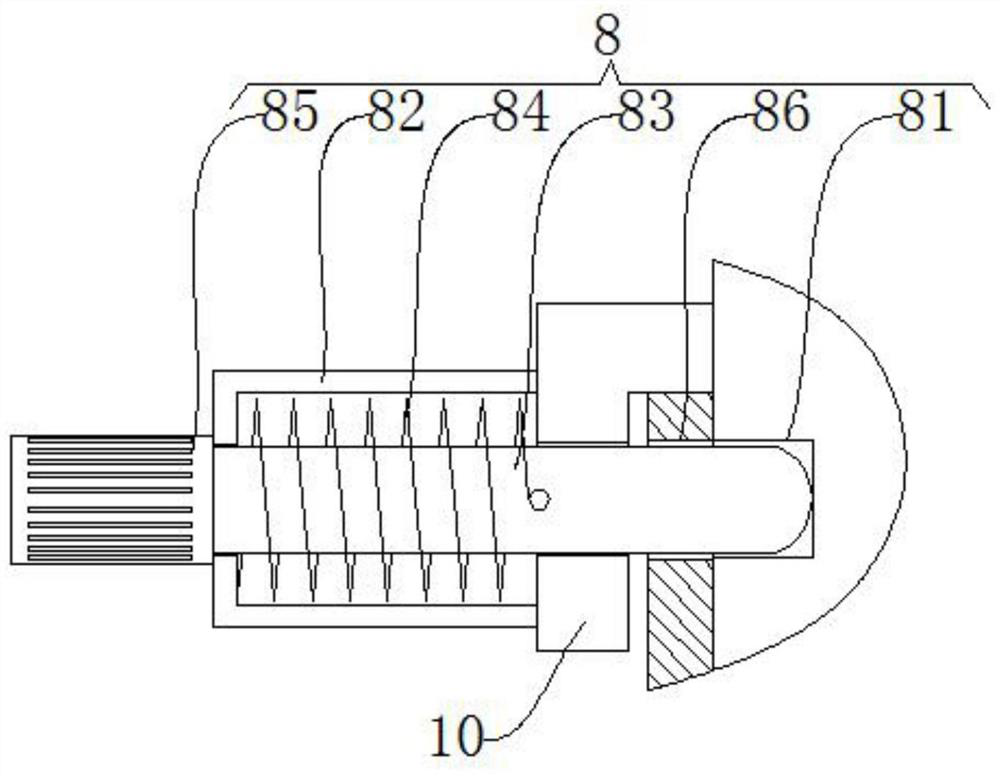

[0025] refer to Figure 1-5 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the side limiting mechanism includes a groove 24 and a side upper plate 23, the groove 24 is provided at one end of the side turning rod 21, and the side upper plate 23 is fixed on On the side plate 2 on the side above the side turning rod 21, the bottom of the side upper plate 23 is rotated and connected with the limit rotating rod 25, and the limit rotating rod 25 is inserted in the groove 24, and the limit rotating rod 25 and the side of the groove 24 A fixing mechanism 9 is arranged between the walls, and the fixing mechanism 9 includes a circular hole 91 and a threaded rod 92. The circular hole 91 is set on the limit rotating rod 25, the threaded rod 92 is fixed on the side wall of the groove 24, and one end of the threaded rod 92 passes through The round hole 91 is connected with a nut 93, the nut 93 is fixed with a rotating plate 94, and the r...

Embodiment 3

[0027] refer to Figure 1-2 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the sliding mechanism includes a sliding hole 12 and a sliding rod 13, the sliding hole 12 is set on one side of the arc-shaped plate 11, and the sliding rod 13 is fixed on the rotating rod 15 On both sides above, one end of the sliding rod 13 passes through the sliding hole 12 and is fixed with a rod limiting plate 14, and the arc-shaped plate 11 can be slidably arranged on the rotating rod 15 through a sliding mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com