Waste battery recycling crusher

A waste battery and crusher technology, applied in battery recycling, waste collector recycling, recycling technology, etc., can solve the problems of waste battery leakage, poor crushing qualification rate, and waste battery storage restrictions, etc. The effect of air-drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

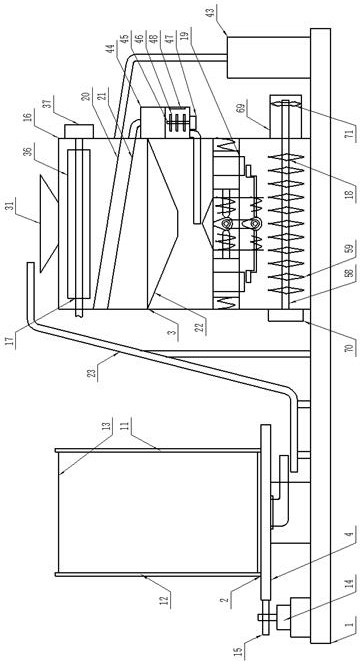

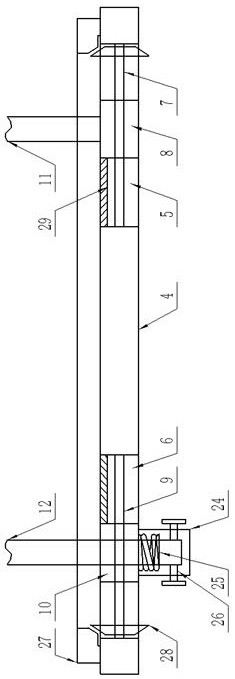

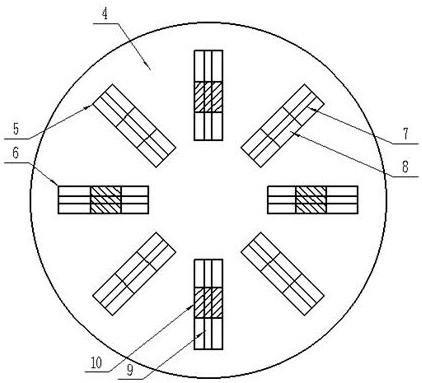

[0021] Embodiment 1: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , a waste battery recycling crusher provided by the present invention is now described, including a base 1, a material preparation mechanism 2 is provided at the upper end of one side of the base 1 in the length direction, and a crushing mechanism 3 is provided at the upper end of the other side, and the material preparation mechanism 2 Including the disc-shaped support frame 4 provided on the upper end of the base 1, the first radial through groove 5 uniformly opened on the disc-shaped support frame 4, and the disc-shaped support frame 4 and located in the first radial direction. The second radial through grooves 6 which are opened between the through grooves 5, the first screw rods 7 and the first radial sliding seats 8 which are arranged in the first radial through grooves 5, and the second radial through grooves The second screw mandrel 9 and the second radial slide seat 10 th...

Embodiment 2

[0022] Example 2: see figure 1 , figure 2 , image 3 Now, a kind of waste battery recycling shredder provided by the present invention will be described, a cylindrical support frame is provided between the lower end wall of the disc-shaped support frame 4 and the upper end wall of the base 1, and the cylindrical support frame is vertical Fixed on the upper end of the base 1, the lower end of the disc-shaped support frame 4 is provided with an annular slot, and the top end of the cylindrical support frame is movably embedded in the annular slot. The disc-shaped support frame 4 The outer circumferential end wall is evenly provided with a first transmission tooth groove in equal arcs, and the first transmission gear 15 is sleeved on the outside of the output shaft of the first motor 14 vertically upward and corresponding to the position of the disc-shaped support frame 4. The gear teeth on the outside of the first transmission gear 15 and the first transmission tooth groove ar...

Embodiment 3

[0023] Embodiment 3: see figure 1 , figure 2 , image 3 , Figure 4 Now, a waste battery recycling shredder provided by the present invention will be described. The mesh belt 13 is a mesh belt body. The adjacent first bracket 11 on one side is connected, and the other end is connected to the first bracket 11 on the other side that is close to it. The first screw rod 7 and the second screw rod 9 are respectively movable through the first bracket 11. A radial sliding seat 8 and a second radial sliding seat 10 are provided. The first radial sliding seat 8 and the second radial sliding seat 10 move through the inner end wall and the first screw rod 7 and the second radial sliding seat 10. Screw mandrel transmission assembly is all provided with between screw mandrel 9 outsides, and ring turret 27 is movable to be provided with at the upper end edge place of described disk-shaped supporting frame 4, and described first screw mandrel 7, second screw mandrel 9 are close to descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com