Metal composite material forging device

A metal composite material and symmetrical technology, applied in forging/pressing/hammer devices, metal processing equipment, manufacturing tools, etc., can solve problems affecting the precision of forgings, knocking deflection, falling, etc., to achieve simple operation and use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

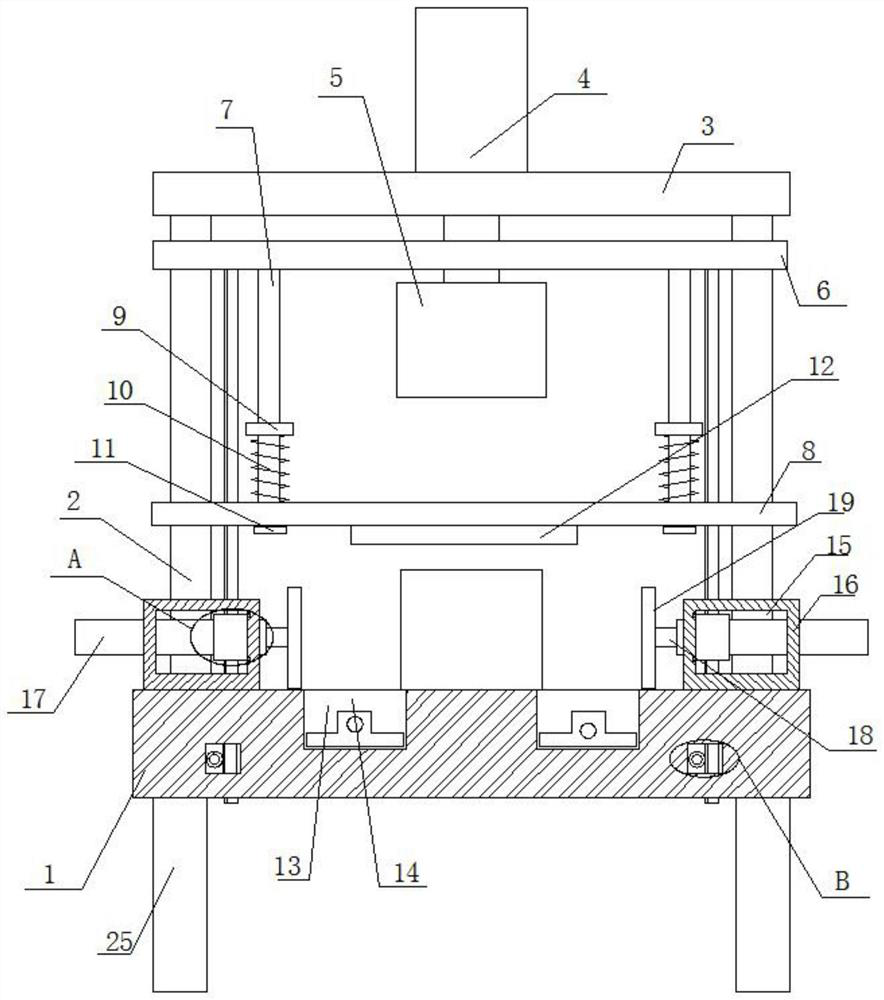

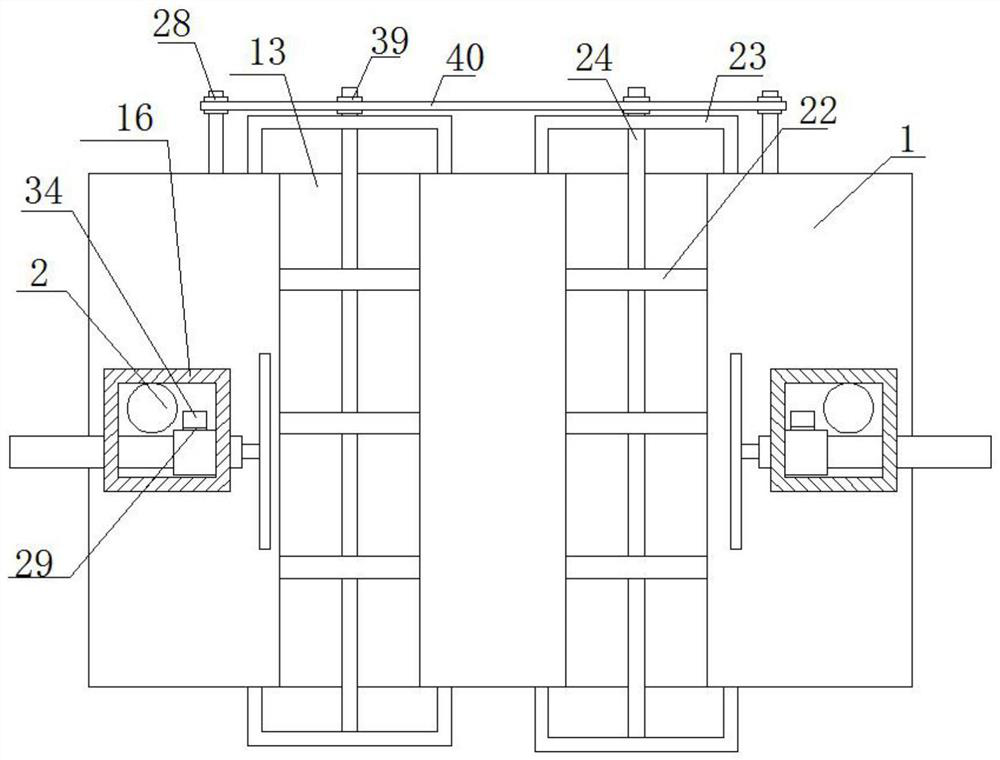

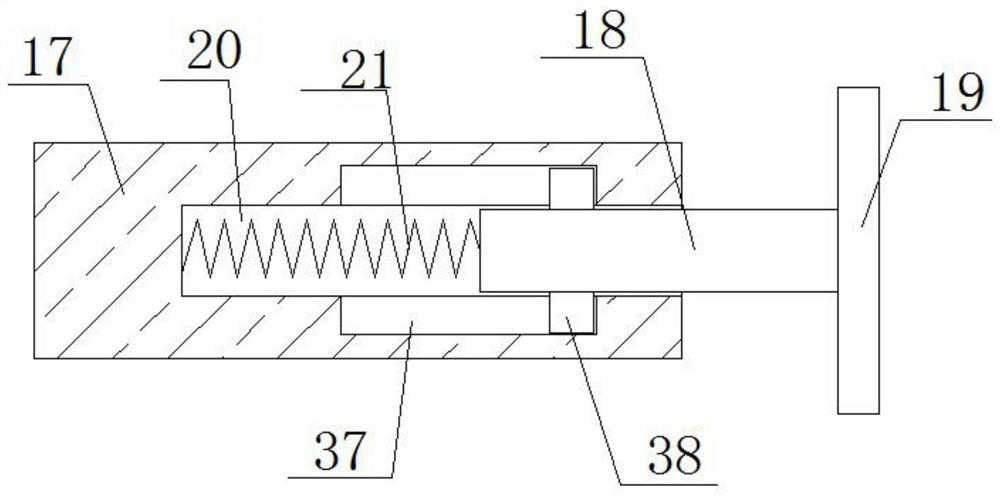

[0029] refer to Figure 1-5 , a metal composite forging device, comprising a base 1, the top of the base 1 is rotatably connected to two symmetrically arranged support rods 2, the top ends of the two support rods 2 are rotatably connected to the same top plate 3, and the top of the top plate 3 is fixedly installed There is a cylinder 4, a forging hammer 5 is fixedly installed on the piston of the cylinder 4, a push plate 6 and a moving plate 8 are movably connected to the two support rods 2, and the push plate 6 is fixedly connected with the piston of the cylinder 4, the bottom of the push plate 6 Two symmetrically arranged push rods 7 are fixedly installed, and the push rod 7 is slidingly connected with the moving plate 8. The bottom of the moving plate 8 is fixedly installed with a backing plate 12, and the supporting rod 2 is rotatably connected with a positioning box 16, which slides on the positioning box 16. A moving rod 17 is connected, and the ends of the two moving ro...

Embodiment 2

[0040] refer to Figure 1-5 , a metal composite forging device, comprising a base 1, the top of the base 1 is rotatably connected to two symmetrically arranged support rods 2, the top ends of the two support rods 2 are rotatably connected to the same top plate 3, and the top of the top plate 3 is connected by bolts A cylinder 4 is fixed, and a forging hammer 5 is welded on the piston of the cylinder 4. A push plate 6 and a moving plate 8 are movably connected to the two support rods 2, and the push plate 6 is fixedly connected to the piston of the cylinder 4. The bottom of the push plate 6 Two symmetrically arranged push rods 7 are welded, the push rod 7 is slidably connected with the moving plate 8, the bottom of the moving plate 8 is welded with a backing plate 12, the supporting rod 2 is rotatably connected with a positioning box 16, and the positioning box 16 is slidably connected with a Moving rod 17, one end of the two moving rods 17 close to each other is slidably conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com