Device and method for removing plating layer on inner wall of porous structure of filter

A hole-shaped structure and filter technology, which is applied in the field of removal device for the inner wall of the filter hole-shaped structure, can solve the problems of low processing efficiency, unguaranteed stability, and increased cost, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

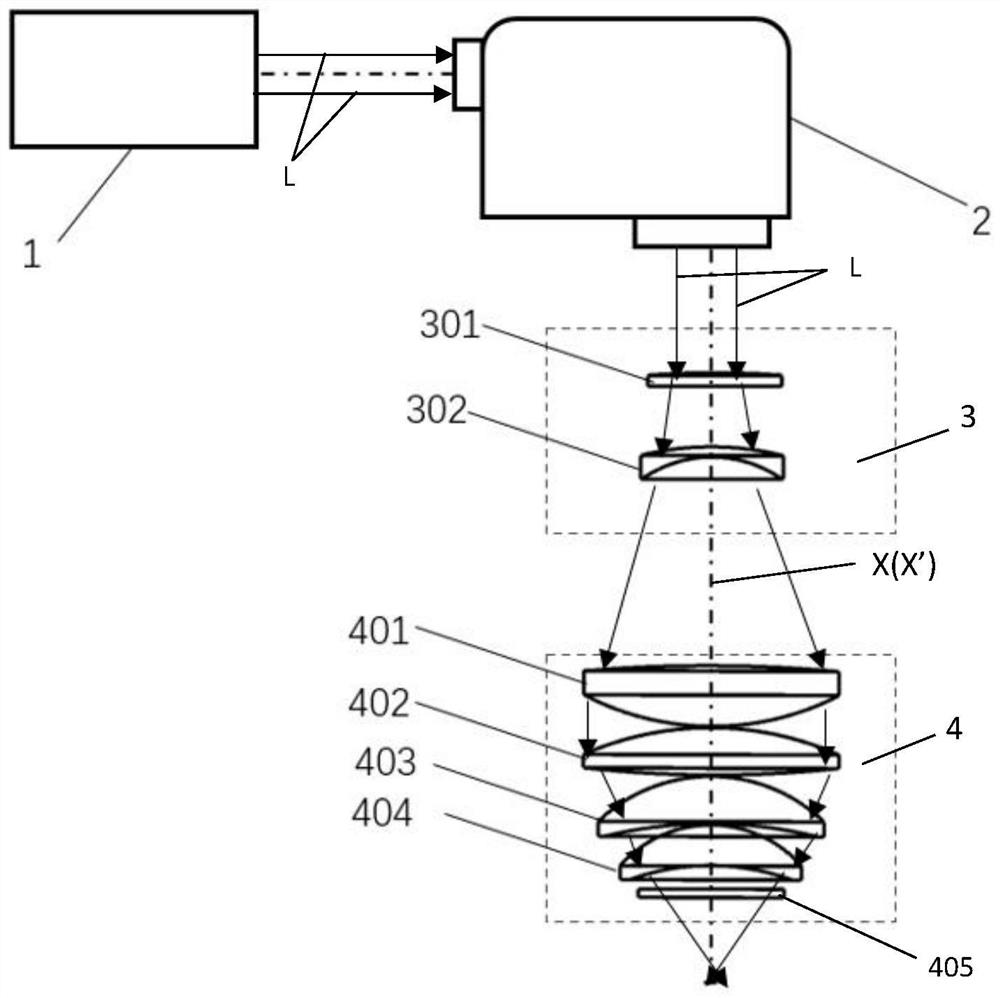

[0030] Such as Figure 1-2 As shown, the present embodiment provides a device for removing the coating on the inner wall of the filter hole structure, which includes:

[0031] a laser 1, which is used to generate and output a laser beam L;

[0032] A vibrating mirror 2, which is used to deflect the laser beam L output by the laser 1, so as to adapt to the coating removal requirements of different formats;

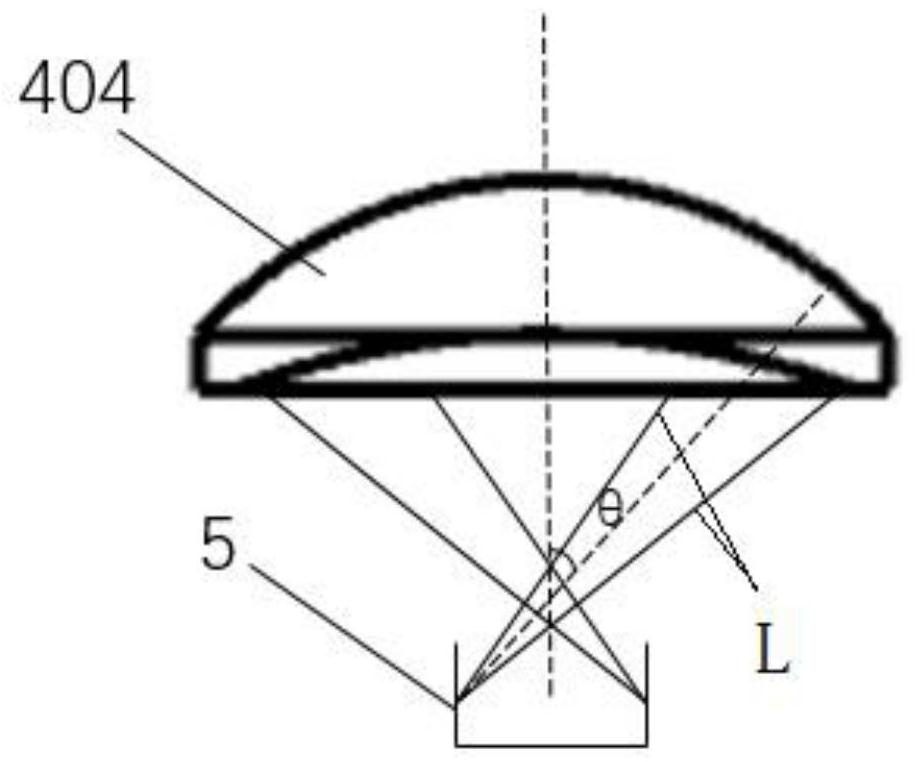

[0033] Lens group 3 and focusing lens group 4, the laser beam L emitted from the galvanometer 2 enters the focusing lens group 4 after changing the angle through the lens group 3, and the focusing lens group 4 processes the laser beam L so that the laser beam L from the focusing lens group The laser beam L emitted in 4 has an inclination angle θ, and acts on the inner wall of the filter hole structure 5 to realize the removal of the coating on the inner wall of the filter hole structure. In this embodiment, the inclination angle θ satisfies the condition: 30°≤θ≤60 ° (pref...

Embodiment 2

[0037] The only difference between this embodiment and Embodiment 1 is that the device for removing the coating on the inner wall of the filter hole structure also includes:

[0038] The first movement module, which is connected to the vibrating mirror 2, is used to drive the vibrating mirror 2 to move along the optical axis X' of the laser beam L output from the vibrating mirror 2, so as to adjust the distance between the vibrating mirror 2 and the lens group 3. The distance can further adjust the aperture size of the spot to meet the removal requirements of different coatings.

Embodiment 3

[0040] The only difference between this embodiment and Embodiment 1 or 2 is that the lens group 3 includes:

[0041] The plano-convex lens 301 located at the incident end and the plano-convex lens 302 located at the exit end, and the optical axes of the plano-convex lens 301 and the plano-concave lens 302 coincide, the exit angle of the laser beam changes after the comprehensive action of the plano-convex lens 301 and the plano-concave lens 302, such as the exit angle become bigger;

[0042] Meanwhile, the focusing lens group 4 includes:

[0043] The first biconvex lens 401, the first biconvex lens 402, the first meniscus lens 403, the second meniscus lens 404 and the protective lens 405 arranged in sequence along the direction from the incident end to the exit end, through the plano-concave lens 302 of the lens group 3 After the laser beam passes through the comprehensive action of the first lenticular lens 401, the first lenticular lens 402, the first meniscus lens 403, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com