Feeding and discharging pushing mechanism of laser marking device

A technology of laser marking and pushing mechanism, applied in the field of laser marking machines, can solve the problems of untimely retraction and extension of lifting blocks, damage to parts and equipment, low feeding efficiency, etc., so as to reduce waiting time and achieve accurate position. , smooth sliding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

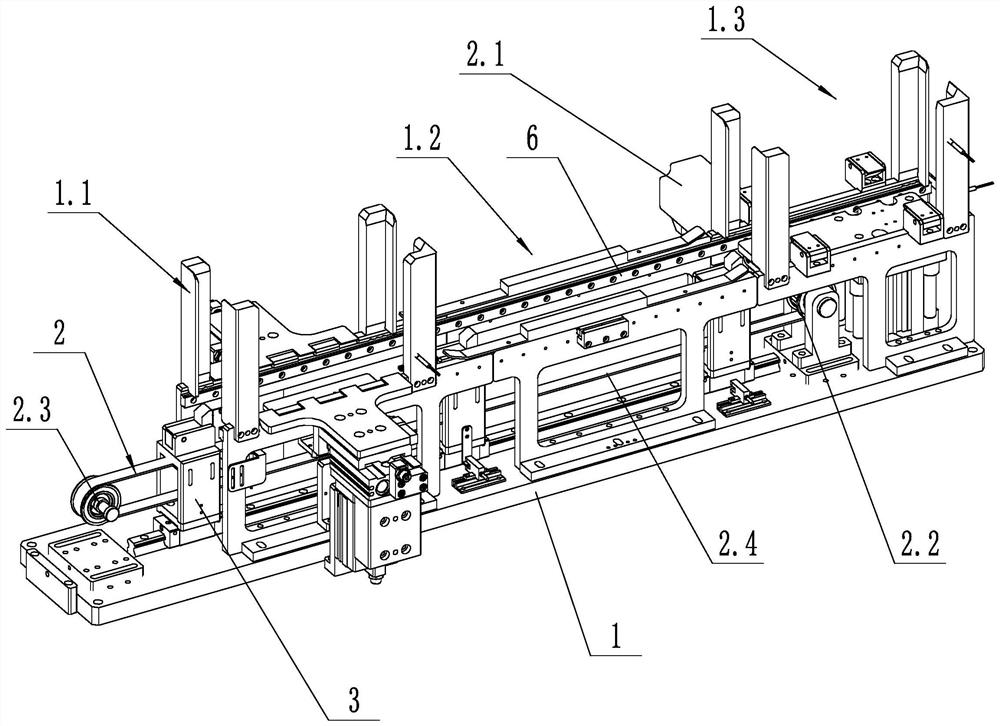

[0030] Such as figure 1 As shown, a laser marking device loading and unloading push mechanism includes a support frame 1, a push drive mechanism 2, a push assembly 3 and a tray, the tray is arranged on the support frame 1 and is slidably connected with the support frame 1, and the push drive mechanism 2 is fixed On the support frame 1, the support frame 1 includes a loading station 1.1, a processing station 1.2 and a blanking station 1.3, and the push assembly 3 can span the loading station 1.1, processing station under the action of the driving mechanism 2. Station 1.2 and unloading station 1.3, push the tray with products from loading station 1.1 to processing station 1.2, and then push the processed tray from processing station 1.2 to unloading station 1.3. There are two pushing assemblies 3, and the two pushing assemblies 3 are arranged at intervals of one station. The two push assemblies 3 are connected with the same push drive mechanism 2 . The driving mechanism 2 incl...

Embodiment 2

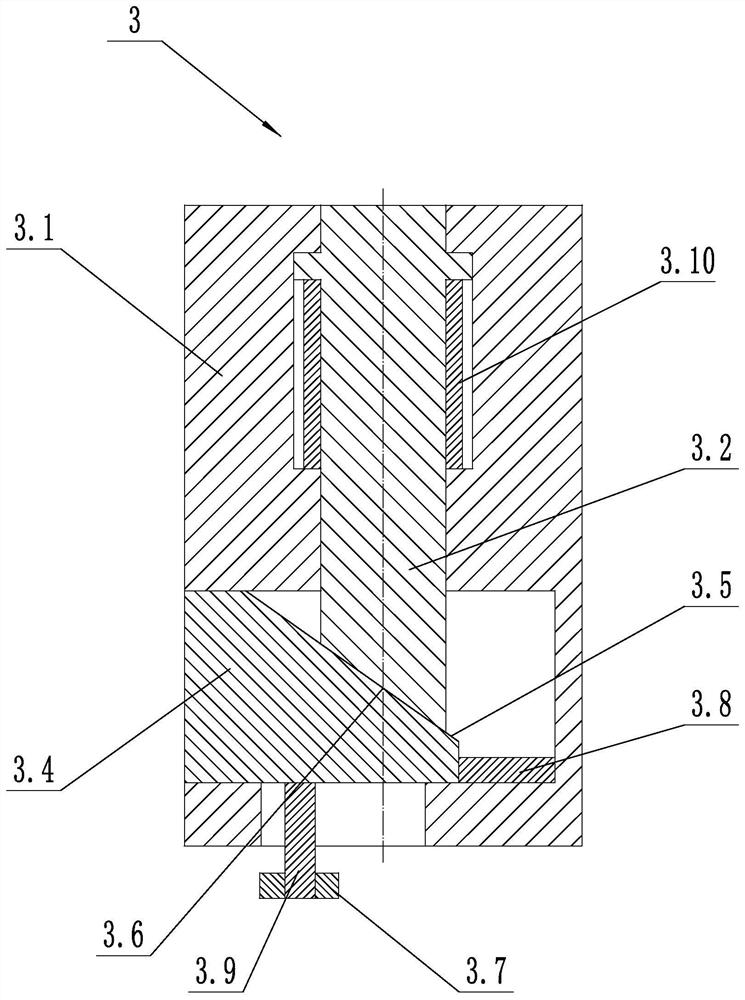

[0034] Such as image 3 As shown, the pushing assembly 3 further includes a third spring 3.10, one end of the third spring 3.10 is connected to the lifting block 3.2, and the other end of the third spring 3.10 is connected to the sliding and fixing block 3.1. The third spring 3.10 is a telescopic spring. The third spring 3.10 can make the lifting block 3.2 drop in time when the traverse block 3.4 retreats, so as to avoid the lifting block 3.2 from being stuck due to the effect of friction.

Embodiment 3

[0036] The first slope 3.5 is slidingly connected to the second slope 3.6 through a dovetail slider mechanism. The structure can make the traversing block 3.4 move together with the lifting block 3.2 to ensure stable switching between the two states and avoid the lifting block 3.2 from being stuck due to friction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com