Portable rock slice polishing auxiliary device and operation method

An auxiliary device and portable technology, applied in grinding/polishing equipment, surface-polished machine tools, manufacturing tools, etc., can solve the problems of low yield and quality of rock slices, hand injury during the polishing process of rock slices, etc., and save energy. And the consumption of raw materials, improve the polishing quality, reduce the effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below with reference to the accompanying drawings and through specific embodiments. Among them, the positional nouns such as "up" and "down" mentioned in this article are represented by figure 1 orientation for reference.

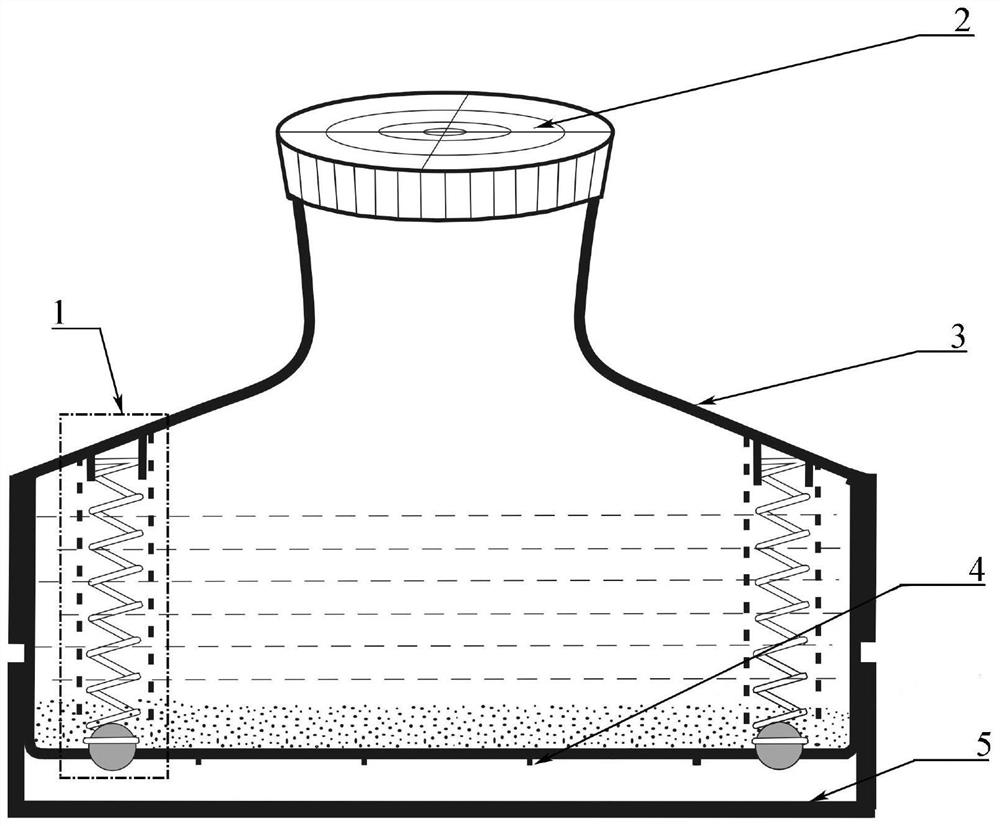

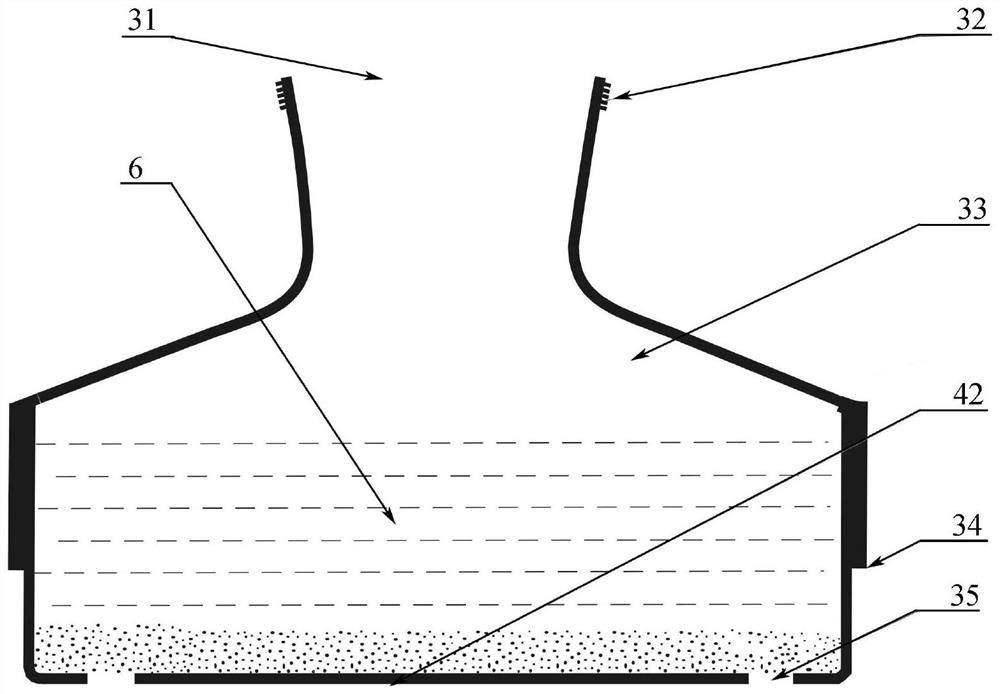

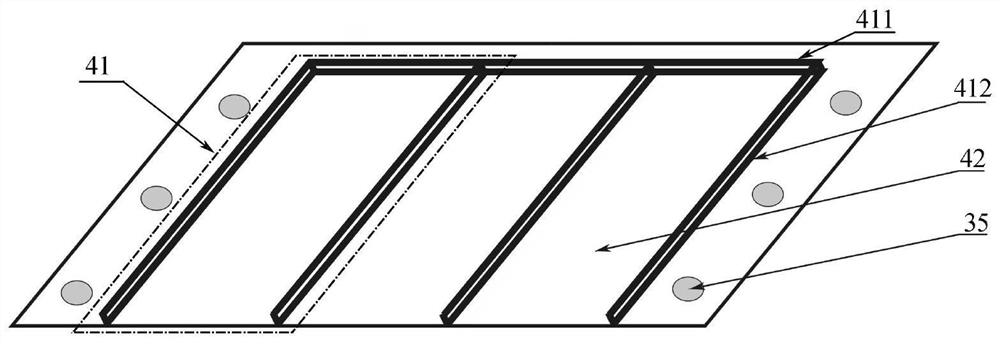

[0038] like figure 1 As shown, a portable rock slice polishing auxiliary device proposed by the present invention includes: an auxiliary device 3, a liquid outlet mechanism 1, a level measuring instrument 2 and an attachment mechanism 4, and a liquid storage cavity 33 is formed in the auxiliary device 3, A liquid inlet 31 and a plurality of liquid outlets 35 are provided; multiple groups of liquid outlet mechanisms 1 are arranged in the liquid storage cavity 33, and the liquid outlet mechanism 1 can control the resistance of the liquid outlet 35; the level measuring instrument 2 is arranged in the auxiliary device 3; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com