Shredding device for sweet potato vermicelli production

A sweet potato vermicelli and shredding technology, applied in climate change adaptation, food science, metal processing, etc., can solve problems such as low efficiency and labor consumption, and achieve the effects of convenient replacement, improved efficiency, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

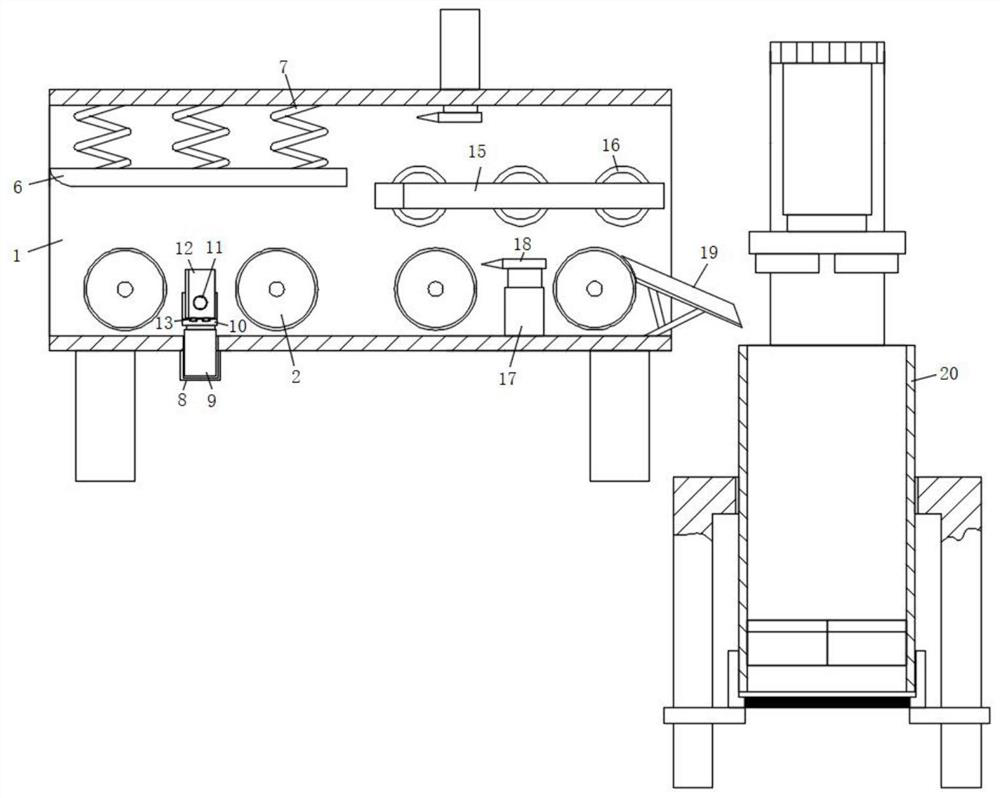

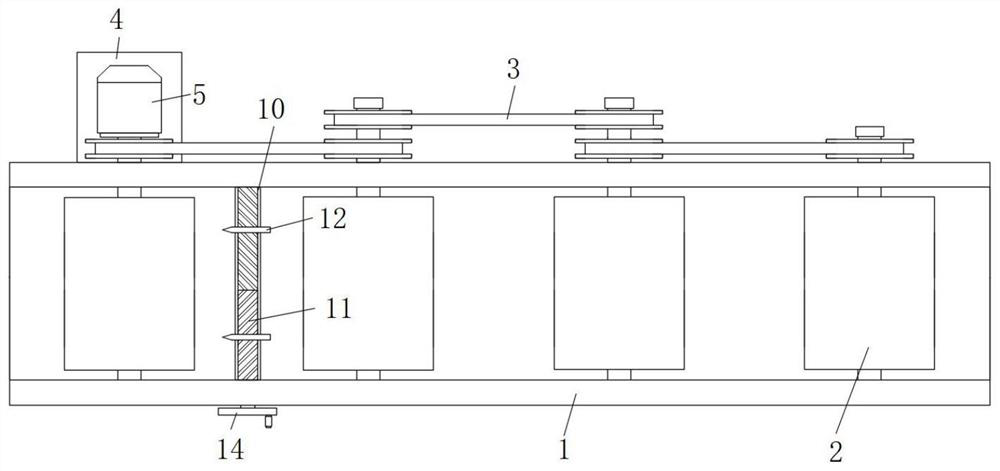

[0032] refer to Figure 1-5 , a kind of shredding device for producing sweet potato vermicelli, comprising a shaping dish 1, the front and rear sides of the lower end of the inner wall of the shaping dish 1 are rotationally connected with conveying rollers 2, and the rear ends of two adjacent conveying rollers 2 pass through the shaping dish 1 and are connected at the end Connected through the rotation of the conveyor belt 3, a horizontal plate 4 is fixedly connected to the rear end of the shaping dish 1, and a servo motor 5 is fixed to the top surface of the horizontal plate 4 through screws, and the output end of the servo motor 5 is fixedly connected to one of the conveying rollers 2 One side of the shaping dish 1 is provided with a pressing plate-6, and an extrusion spring-7 is fixedly connected between the pressing plate-6 and the inner top surface of the shaping dish 1, and an installation tube is fixed on the side of the bottom surface of the shaping dish 1 close to the ...

Embodiment 2

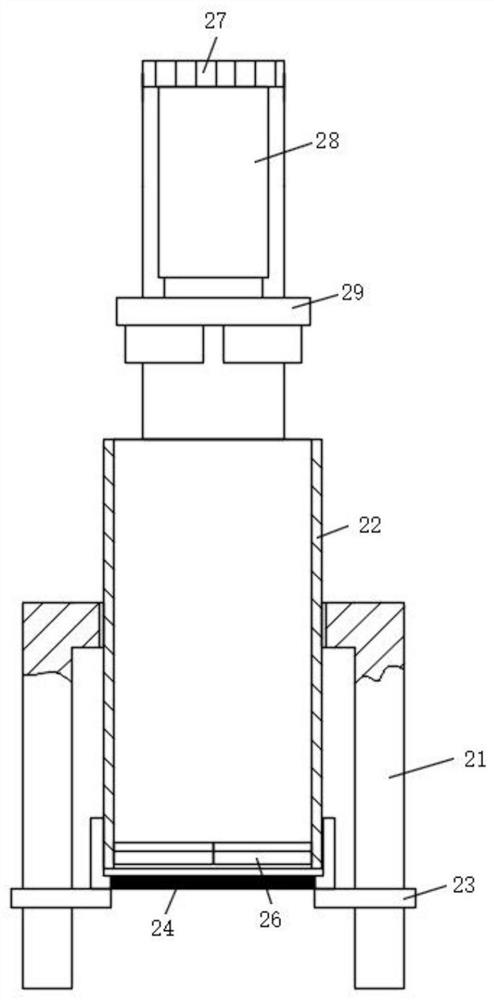

[0035] Such as image 3 and 6 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the extruding assembly 29 includes a pressing plate 30, the shape of the pressing plate 30 matches the inner wall of the extruding dish 22, and the bottom surface of the pressing plate 30 is also fixed with a triangular pressing block 31, the triangular pressing block 31 There are four pressing blocks 31 and they are evenly distributed on the bottom surface of the pressing plate 30 .

[0036] In this embodiment, four triangular pressing blocks 31 are provided and evenly distributed on the bottom surface of the pressing plate 30, so that the pressing plate 30 can pass through the cutting tool 26 to completely press and shred the sweet potato pieces.

Embodiment 3

[0038] Such as figure 1 and 2 As shown, this embodiment is basically the same as Embodiment 1. Preferably, there are multiple conveying rollers 2 that are evenly distributed on the lower inner wall of the shaping dish 1 .

[0039] Extrusion spring one 7 and extrusion spring two 16 are all provided with a plurality of and evenly distributed on the bottom surface of pressing plate one 6 and pressing plate two 15 end surfaces.

[0040] In this embodiment, the pressure spring one 7 and the pressure spring two 16 are provided with a plurality and evenly distributed on the bottom surface of the pressure plate one 6 and the end surface of the pressure plate two 15, so that the pressure plate one 6 and the pressure plate two 15 move more smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com