A kind of overturning mold and method for preparing inorganic composite material profiles

A technology of inorganic composite materials and profiles, which is applied in the direction of manufacturing tools, unloading devices, ceramic molding machines, etc., can solve the problems of materials that cannot reach the bottom, easy to block materials, etc., so as to reduce the difficulty of molding and demolding, and improve production efficiency. , the effect of saving material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The present invention also provides a preparation method for the new type of inorganic composite material RPC profile, including the steps as follows:

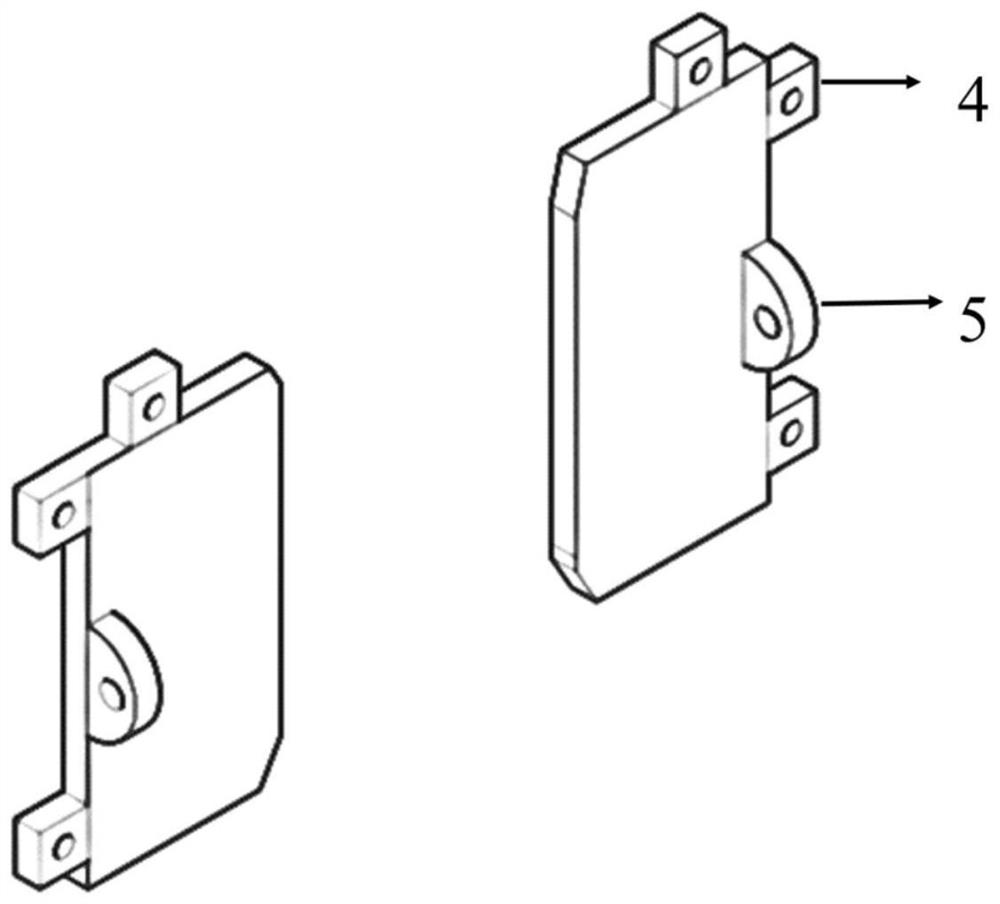

[0053] Step (1) Put the mold according to Figure 5 Installation, the four -forming board end baffle 1 and the molding board 2 are based on the position of the corresponding fastener device 4 to fix the baffle and the molding plate of the screw.

[0054] Step (2) Install the flip mechanism 3 at the bottom of the molding board. By rotating the on both sides, the formation board 2 is the Image 6 To.

[0055] Step (3) This experiment is equipped with the pressure -resistant strength after maintenance of 200MPA, 300MPA and 400MPa RPC slurry, which can be used to prepare RPC profiles of different sizes to meet multi -directional needs. Figure 13 Essence

[0056] Step (4) Pour the prepared pulp into the mold concrete molding area, so that the center of the slurry is slightly higher than the edge of the mold, and the vibration mold...

Embodiment

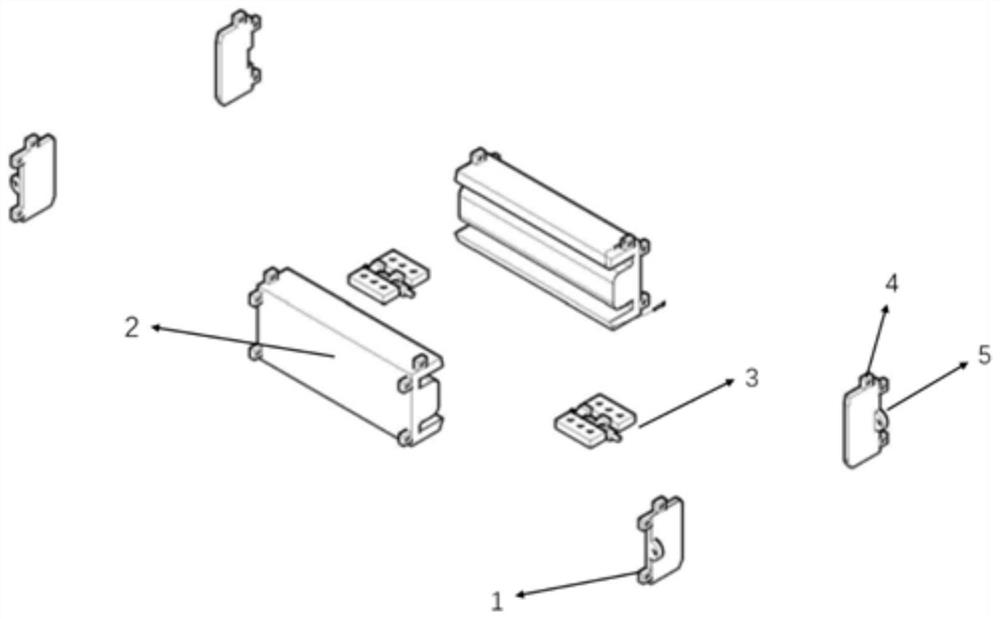

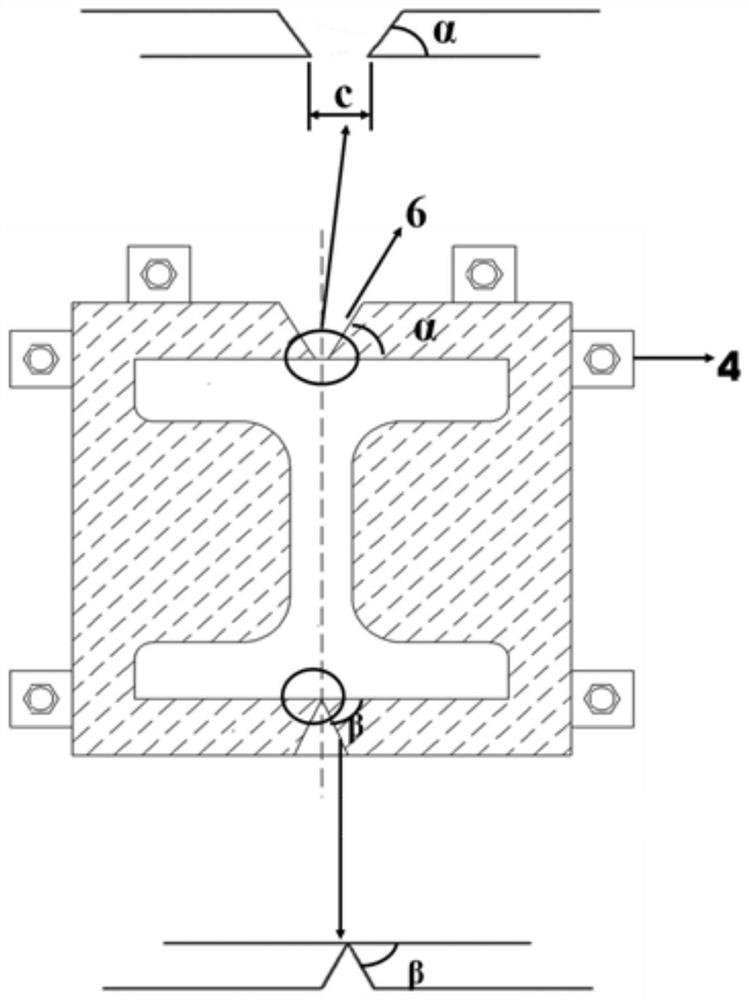

[0065] Taking the preparation intensity of the workcase of 200MPa as an example, such as Figure 13 It shows that the present invention provides a production mold of RPC industrial profiles. The molds include two molding boards 2, four -forming board end baffle 1 and flip mechanism 3 (see figure 1 To. The corresponding fastening device of the molding board 2 and the baffle 1 of its end 1 is fixed through the screws, so that the four baffle 1 is fixed on the end of the two molding boards 2 to form the formation area of the RPC concrete (such as such as such as such as such as the formation Figure 5 Show). Install the flip mechanism 3 at the bottom of the molding board, rotate the molding board 2 to the horizontal position (see Image 6 ), The mold is the open position. Next, pour the slurry to the concrete formation area and place the mold on the vibration platform. The center part of the slurry should be slightly higher than the edge of the mold. The rotating mold merges the mold,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com