Rapid and accurate gypsum plate turning device

A gypsum, accurate technology, used in conveyor controls, transport and packaging, furnaces, etc., to solve problems such as inability to turn over, low accuracy, and gypsum board stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

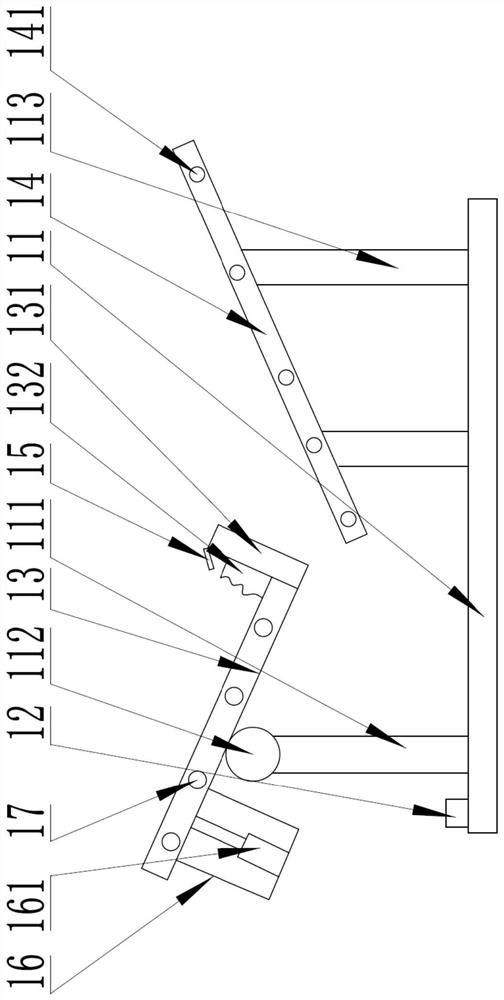

[0023] see figure 1 , a fast and accurate gypsum turnover device, including a base plate 11, the base plate 11 is used as a mounting plate, preferably, welded by square steel; also includes a controller 12, the controller 12 is controlled by Mitsubishi PLC device, which adopts a model of: FX3U-48MT / ES-A; and burns related programs in the controller 12; the front and rear sides of the base plate 11 are equipped with a first support column 111 through bolts, and the first support column The top of 111 is provided with a shaft hole, and a shaft 112 is connected through the shaft hole, and a first turning plate 13 is fixed on the shaft 112, and the first turning plate 13 can rotate around the shaft 112; The end of the turning board 13 is provided with a baffle 131 for preventing the gypsum from falling.

[0024] On the bottom plate 11, a side near the baffle plate 131 is provided with a second support column 113, and the second support columns 113 are 4 in total, arranged in a re...

Embodiment 2

[0028] Embodiment 2 is a further improvement to Embodiment 1, and the same parts will not be repeated here, please refer to figure 1 A mounting frame 16 is provided below the first flipping plate 13, and an electric push rod 161 is arranged inside the mounting frame 16. The mounting frame 16 can rotate together with the first flipping plate 13, and the electric push rod 161 is completely When shrinking, the upper surface of the electric push rod 161 should be lower than the first flip plate 13, and when the electric push rod 161 is fully extended, the upper surface of the electric push rod 161 should be higher than the first flip plate 13: 5-10cm, to ensure the electric The push rod 161 can push up the gypsum board on the first turning board 13, and more accurately and quickly realize the turning over of the gypsum board; preferably, in order to ensure that the electric push rod 161 can pass through the first turning board 13, the second A turning plate 13 is arranged as a hol...

Embodiment 3

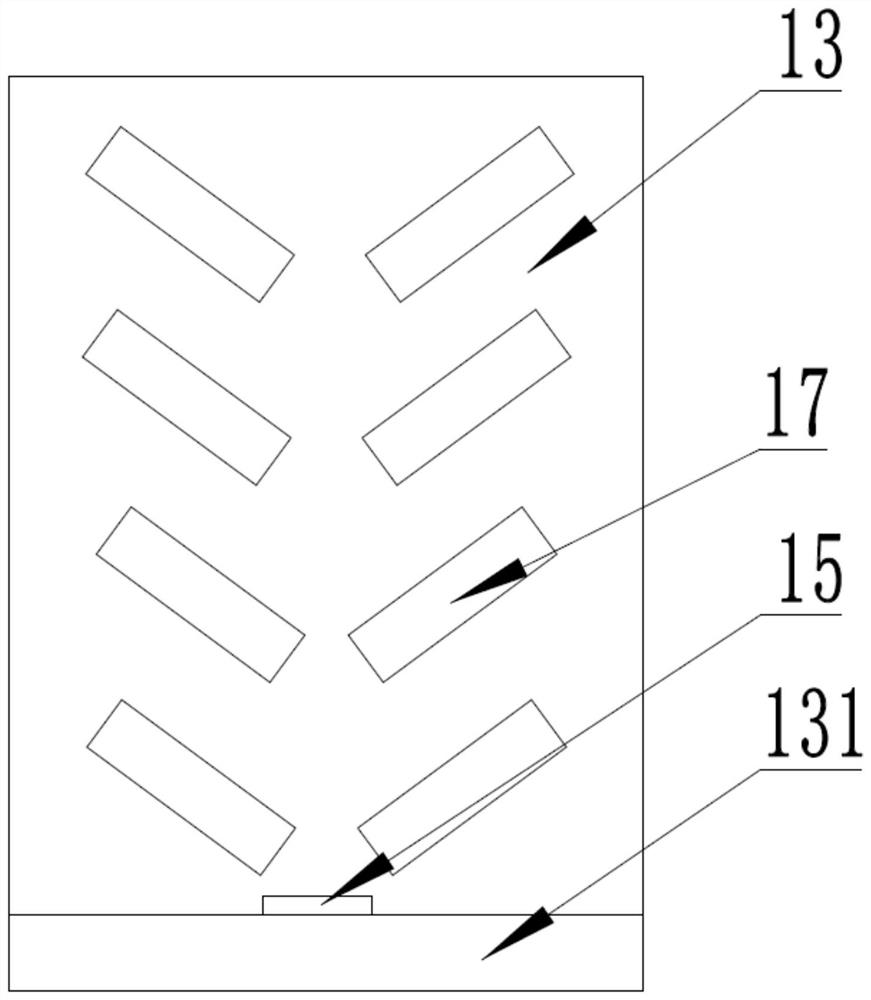

[0031] Embodiment 3 is a further improvement to Embodiment 1, and the same parts will not be repeated here, please refer to figure 1 and figure 2 , the first overturning plate 13 is provided with rollers 17 which are arranged symmetrically. There is a certain angle between the two groups of rollers 17, which is V-shaped. A certain deflection cannot keep the gypsum board in the middle position of the first turning board 13 all the time, resulting in the failure of the normal turning of the gypsum board. Move to the middle while moving, so that the gypsum board is finally located in the middle of the first turning board 13, so as to ensure the normal turning of the gypsum board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com