A kind of continuous gas-phase hydrogenation of methyl acrylate to methyl propionate technology

A technology for producing methyl acrylate and methyl propionate, which is applied in the preparation of carboxylic acid esters, the preparation of organic compounds, organic chemistry, etc., and can solve the problems of product yield reduction, self-polymerization blockage of reactors and hydrogenation system pipelines, and self- Polymerization and other problems, to reduce the risk of side reactions, protect the sintering deactivation, the effect of reasonable process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

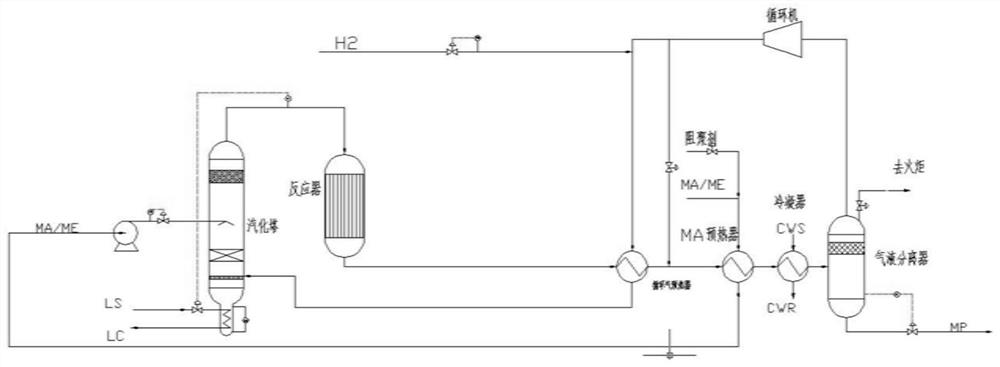

[0040] Such as figure 1 As shown, the process consists of the following key equipment and steps:

[0041]Key equipment includes vaporization tower, reactor, cycle gas preheater, methyl acrylate preheater (MA preheater), condenser, and cycler.

[0042] The mass fraction is 47% methyl acrylate, 53% methanol mixture, enter the MA preheater to preheat to 60 ℃, fresh H 2 with cycle H 2 After mixing, it is preheated to 70°C by the circulating gas preheater, and the gas and liquid phase materials enter the vaporization tower together, and the polymerization inhibitor hydroquinone is intermittently fed according to the content of the tower bottom, and the content of the polymerization inhibitor in the bottom bottom of the vaporization tower is controlled At 200ppm, the vaporizer pressure is maintained at 1MPa. The 1.5MPa (G) steam is used to supply heat to the bottom of the vaporization tower to vaporize methyl acrylate and methanol, and the vaporized mixture at 80°C is discharged ...

Embodiment 2

[0055] Key equipment includes vaporization tower, reactor, cycle gas preheater, methyl acrylate preheater (MA preheater), condenser, and cycler.

[0056] A mixture of methyl acrylate and 53% methyl propionate with a mass fraction of 47% enters the MA preheater to preheat to 60°C, fresh H 2 with cycle H 2 After mixing, it is preheated to 70°C by the circulating gas preheater, and the two streams of gas and liquid phase materials enter the gasification tower together. Controlled at 200ppm, the vaporizer pressure is maintained at 1MPa. The 1.5MPa (G) steam is used to supply heat to the bottom of the vaporization tower to vaporize methyl acrylate and methyl propionate, and the vaporized mixture at 80°C is discharged from the top of the tower.

[0057] Table 4 Feed Composition of Evaporation Tower

[0058]

[0059] The gasified gas phase components enter the tube side of the isothermal tube reactor with a space velocity of 2000 / h, and the reactor bed temperature is controlled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap