Production method of anti-counterfeiting silk with anti-counterfeiting function, application of anti-counterfeiting silk and anti-counterfeiting detection method

A production method and silk technology, applied in the field of silk, can solve problems such as unfavorable cost saving, complex process, damaged mechanical and mechanical properties, etc., and achieve the effects of increasing anti-counterfeiting concealment, good anti-counterfeiting concealment, and increasing anti-counterfeiting strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The present embodiment provides a kind of production method of anti-counterfeit silk with anti-counterfeiting function, and described production method comprises:

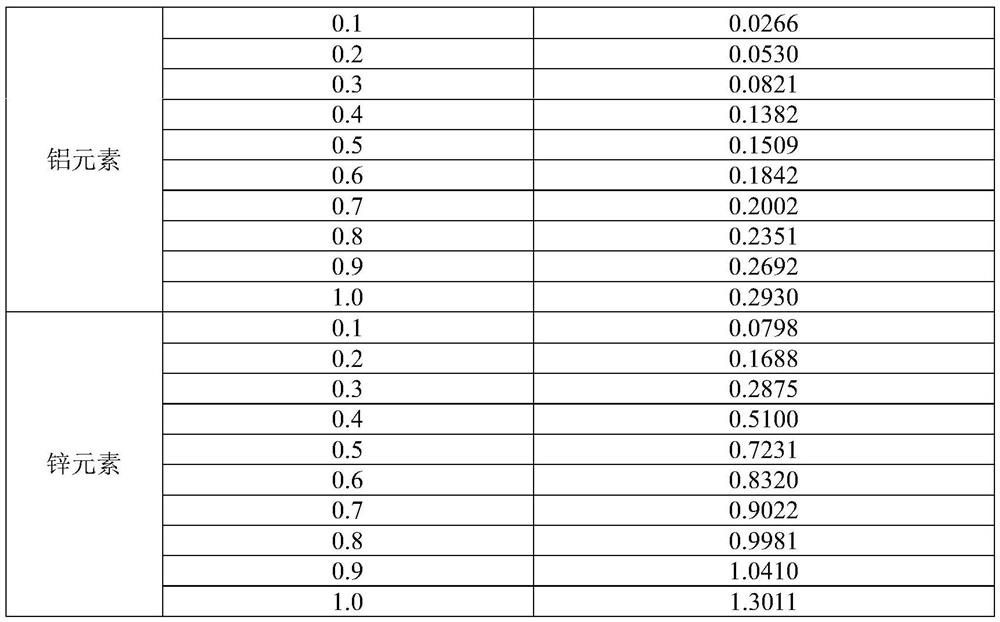

[0052] (1) Prepare composite food: add the anti-counterfeit tracer into water, stir for 10 minutes, and make the anti-counterfeit tracer mixture, wherein the anti-counterfeit tracer consists of zinc oxide, aluminum oxide, strontium oxide and Barium oxide composition (wherein the mass ratio of zinc, aluminum, strontium and barium is 1:2:3:5); then the prepared anti-counterfeit tracer mixture is ultrasonically treated for 20min (ultrasonic frequency 20KHz, ultrasonic power 100W), then mix it with common silkworm feed (see Table 3), add water twice the quality of common silkworm feed and stir evenly, then heat under microwave heating mode for 3min (power is 800W), cooling, make compound food, The sum of the various metal elements contained in the anti-counterfeit tracer accounts for 2.2% of the mass percentage ...

Embodiment 2

[0064] The present embodiment provides a kind of production method of anti-counterfeit silk with anti-counterfeiting function, and described production method comprises:

[0065] (1) Prepare composite food: add the anti-counterfeit tracer into water, stir for 10 minutes, and make the anti-counterfeit tracer mixture, wherein the anti-counterfeit tracer consists of zinc oxide, aluminum oxide, strontium oxide and Barium oxide composition (in which the mass ratio of zinc, aluminum, strontium and barium is 2:1:5:2); then the prepared anti-counterfeit tracer mixture is ultrasonically treated for 20min (ultrasonic frequency 20KHz, ultrasonic power 100W), then mix it with common silkworm feed (see Table 3), add water twice the quality of common silkworm feed and stir evenly, then heat under microwave heating mode for 3min (power is 800W), cooling, make compound food, The sum of the metal elements contained in the anti-counterfeit tracer accounts for 2% of the mass percentage of the co...

Embodiment 3

[0074] The present embodiment provides a kind of production method of anti-counterfeit silk with anti-counterfeiting function, and described production method comprises:

[0075] (1) Prepare composite food: add the anti-counterfeit tracer into water, stir for 10 minutes, and make the anti-counterfeit tracer mixture, wherein the anti-counterfeit tracer consists of zinc oxide, aluminum oxide, strontium oxide and Barium oxide composition (in which the mass ratio of zinc, aluminum, strontium and barium is 1:5:2:2); then the prepared anti-counterfeiting tracer mixture is ultrasonically treated for 20min (ultrasonic frequency 20KHz, ultrasonic power 100W), then mix it with common silkworm feed (see Table 3), add water twice the quality of common silkworm feed and stir evenly, then heat under microwave heating mode for 3min (power is 800W), cooling, make compound food, The sum of the metal elements contained in the anti-counterfeit tracer accounts for 2% of the mass percentage of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com