Assembling method of assembled prefabricated stairs

An assembled and stair technology, applied in the direction of stairs, stair-like structures, construction materials, etc., can solve the problems of inconvenient positioning, fixing and fine-tuning of prefabricated stairs, shaking and other problems, and achieve the effect of improving efficiency and ensuring installation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

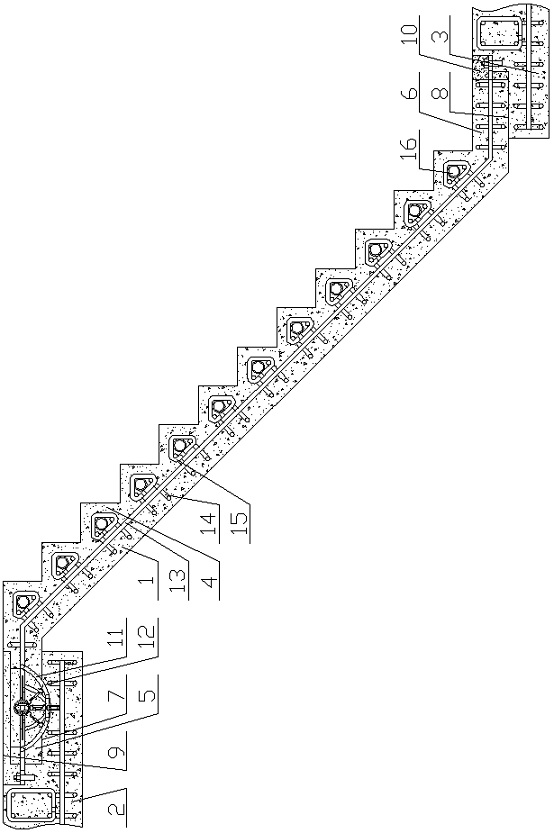

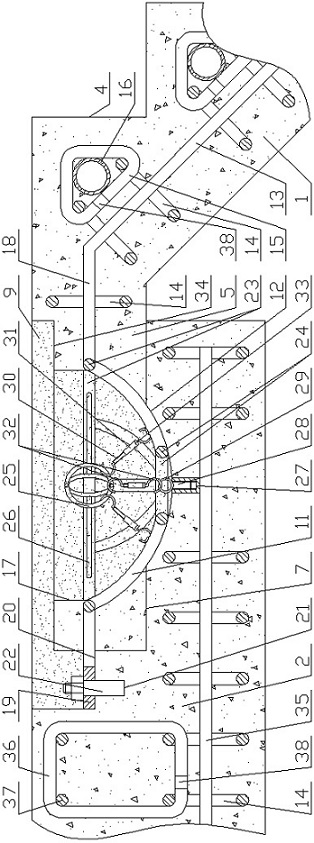

[0056] to combine Figure 1~Figure 2 It can be seen that the assembled prefabricated staircase includes a prefabricated staircase body 1, and the top connection end 5 and the bottom connection end 6 of the prefabricated staircase body 1 are respectively placed with the placement groove A7 provided by the upper ladder platform 2 and the lower ladder platform 3. The slots B8 are respectively connected and fixed, the top connecting end 5 is fixed to the upper ladder platform 2 through the cast-in-place concrete layer A9, and the bottom connecting end 6 is fixed to the lower ladder platform 3 through the cast-in-place concrete layer B10.

[0057] The middle part of the prefabricated staircase body 1 is fixed with a plurality of parallel longitudinal ribs A13 along the length direction of the staircase body 1. The folds are bent longitudinal ribs 18 arranged along the top connection end 5 and the bottom connection end 6 .

[0058] The ends of the bent longitudinal ribs 18 protrude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com