Leveling system based on laser distance measurement and method

A technology of laser distance measurement and laser rangefinder, which is applied to the automatic control system of drilling, earthwork drilling and production, support devices, etc., and can solve problems such as time-consuming, laborious, error, and inconvenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

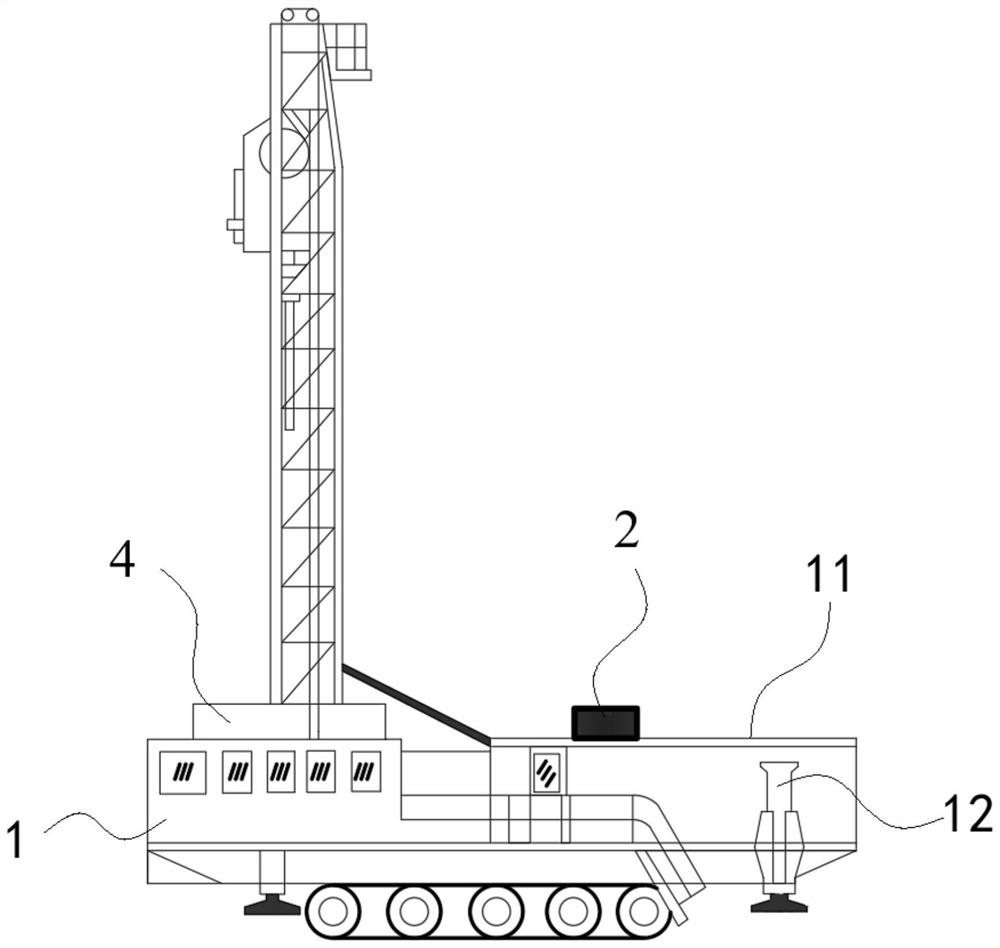

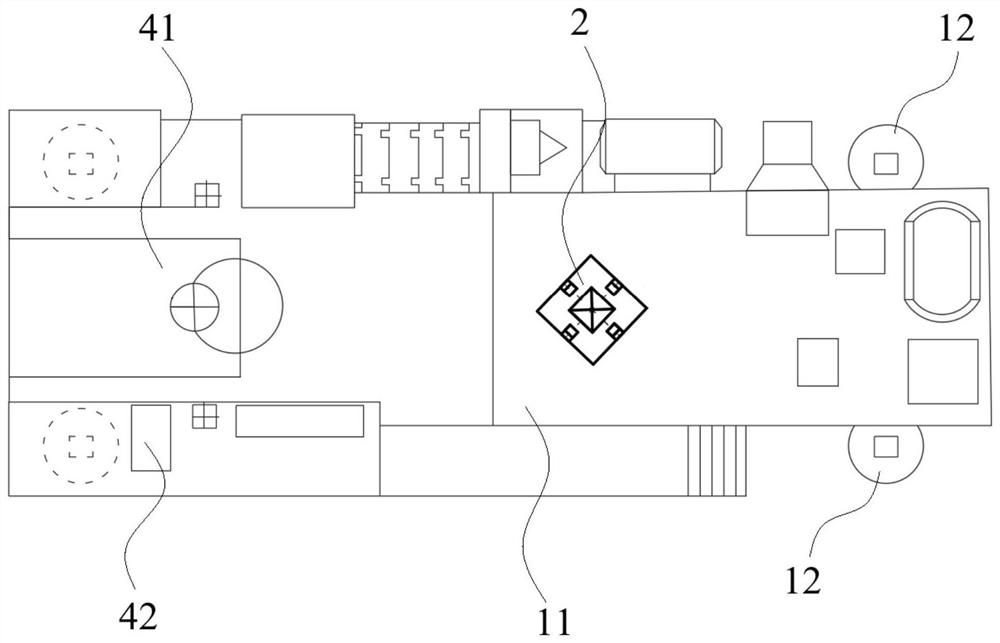

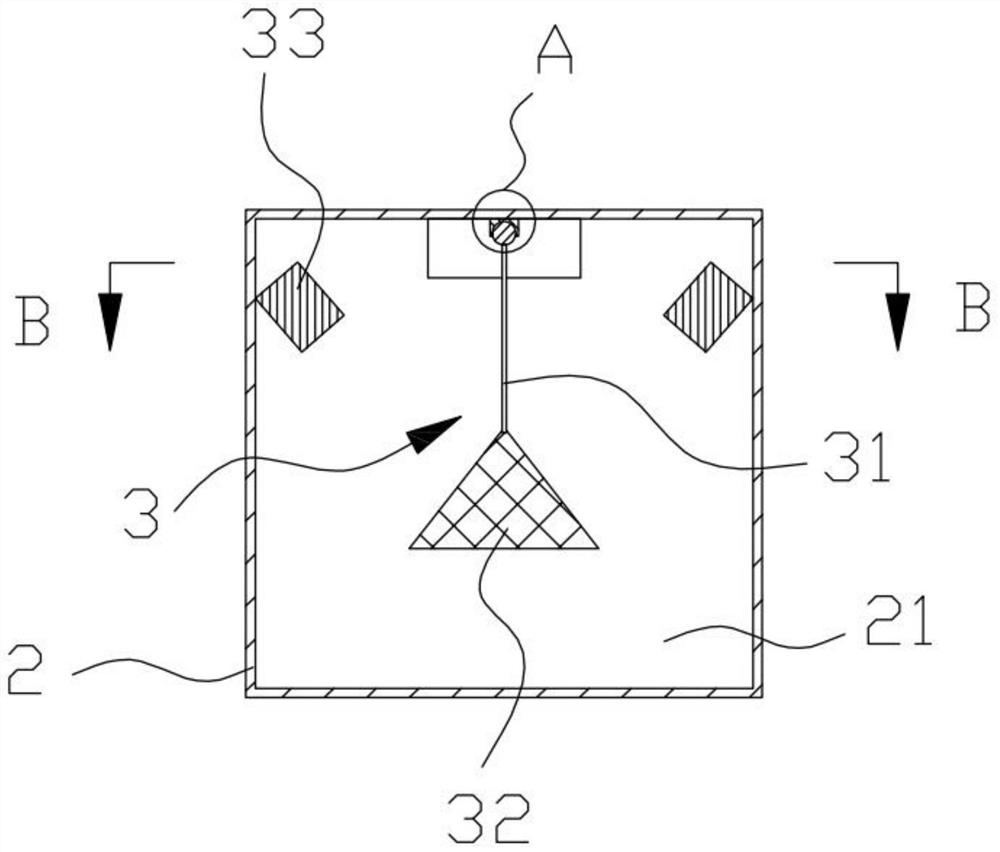

[0031] see figure 1 , The present invention provides a leveling system based on laser ranging, including: a drilling rig assembly 1 , a box body 2 , a distance measuring assembly 3 , and a control assembly 4 .

[0032] Such as Figure 1 to Figure 3 As shown, the drilling rig assembly 1 includes a drilling rig platform 11 and four linear drivers 12 , the four linear drivers 12 are disposed below the drilling rig platform 11 in a rectangular shape, and the output shafts of the linear drivers 12 are connected to the drilling rig platform 11 .

[0033] Further, the linear driving member 12 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com