High-strength flexible stainless steel and stainless steel part made of high-strength flexible stainless steel

A technology of stainless steel and stainless steel plate, applied in shaft lining, tunnel lining, underground chamber, etc., can solve the problems of operation and maintenance safety hazards, limited research results, lack of research and application of tunnel repair engineering, etc., to achieve improved support capacity and firm connection stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The mass percent proportioning of the chemical composition of the present embodiment stainless steel is:

[0040]C: 0.015% Si: 0.30% Mn: 8.45% P: 0.025% S: 0.006%

[0041] Cr: 14.30% Ni: 6.10% N: 0.025% Cu: 2.60%

[0042] The rest is Fe and unavoidable impurities.

[0043] The specification of the stainless steel in this embodiment is 5.5mm, and the tensile strength is 460Mpa.

Embodiment 2

[0045] The mass percent proportioning of the chemical composition of the present embodiment stainless steel is:

[0046] C: 0.020% Si: 0.29% Mn: 8.20% P: 0.030% S: 0.005%

[0047] Cr: 14.50% Ni: 6.30% N: 0.020% Cu: 2.62%

[0048] The rest is Fe and unavoidable impurities.

[0049] The specification of the stainless steel in this embodiment is 11mm, and the tensile strength is 470Mpa.

Embodiment 3

[0051] The mass percent proportioning of the chemical composition of the stainless steel of the present embodiment is:

[0052] C: 0.025% Si: 0.35% Mn: 8.60% P: 0.035% S: 0.010%

[0053] Cr: 14.43% Ni: 6.20% N: 0.026% Cu: 2.70%

[0054] The rest is Fe and unavoidable impurities.

[0055] The specification of the stainless steel in this embodiment is 6.5mm, and the tensile strength is 465Mpa.

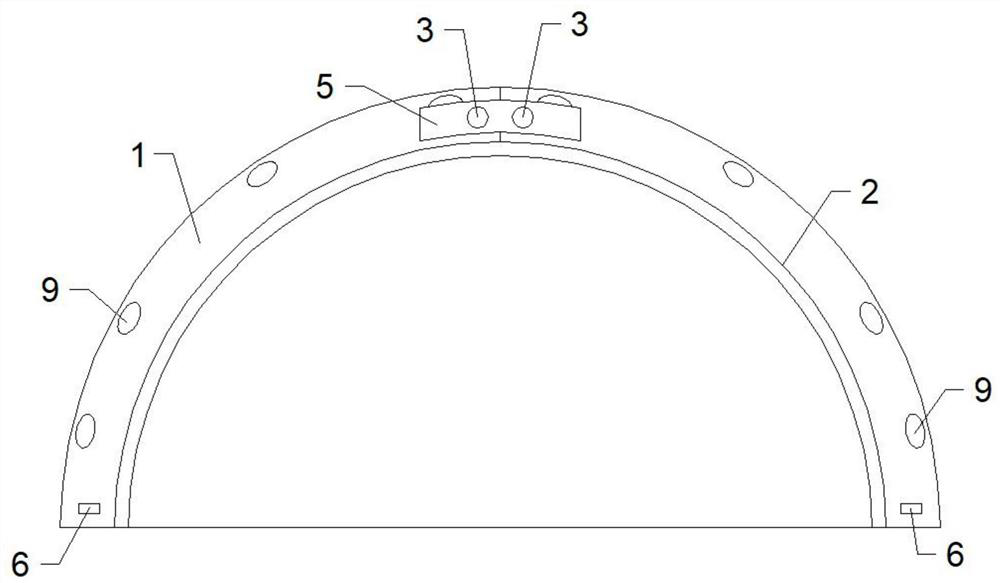

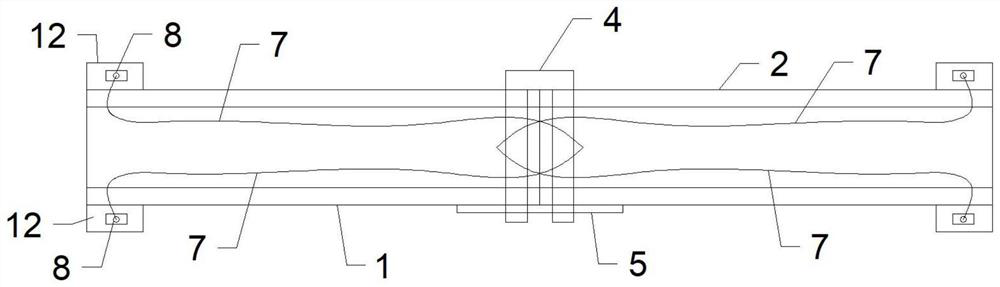

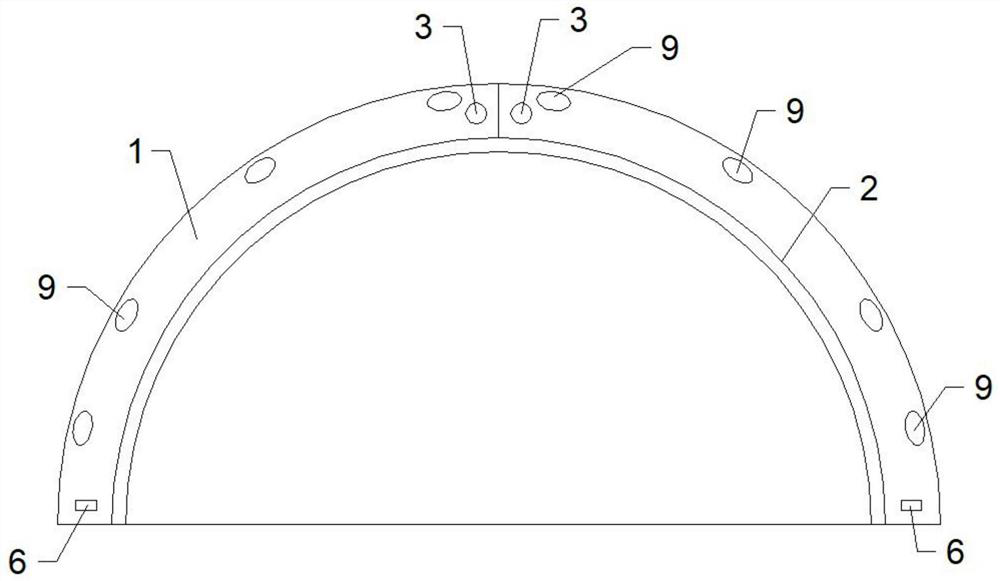

[0056] A high-strength flexible stainless steel and stainless steel parts made of it, including a semi-circular arch, the arch is composed of two quarter rings on the left and right, and the two quarter rings on the left and right are respectively left and right. The arch 1 and the right arch 2, the arch is a U-shaped structure with an upward opening.

[0057] The upper ends of the left arch 1 and the right arch 2 are respectively provided with a connection hole 3, and the connection hole 3 is arranged through the arch along the front and rear direction, and also includes a U-shaped c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com