Engine heat dissipation system used for railway engineering mechanical vehicle

A technology of railway engineering and cooling system, applied in the direction of machine/engine, engine components, engine cooling, etc., can solve problems such as power drop, increased engine temperature, and influence on powertrain layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the following briefly introduces the drawings required for the description of the embodiments or the prior art. Apparently, the drawings in the following description are only some embodiments of the present invention, and those skilled in the art can obtain other embodiments according to these drawings without creative efforts.

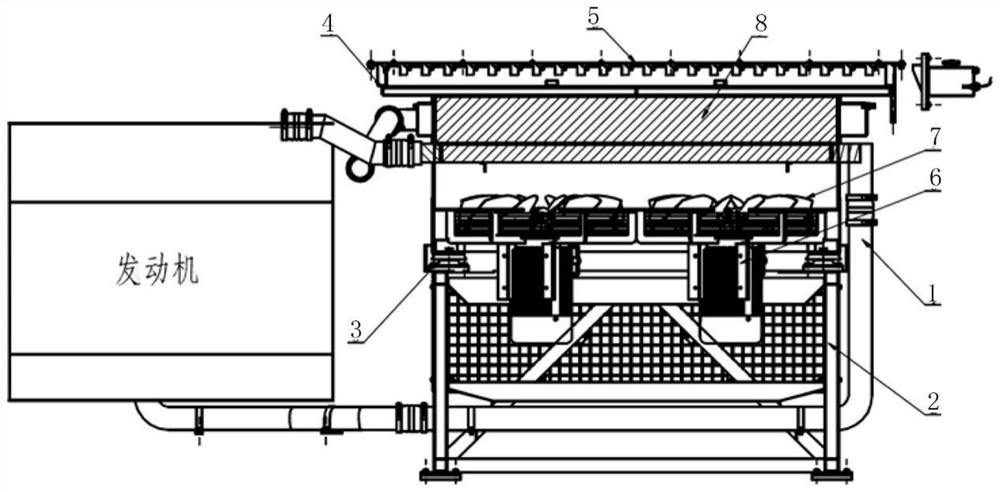

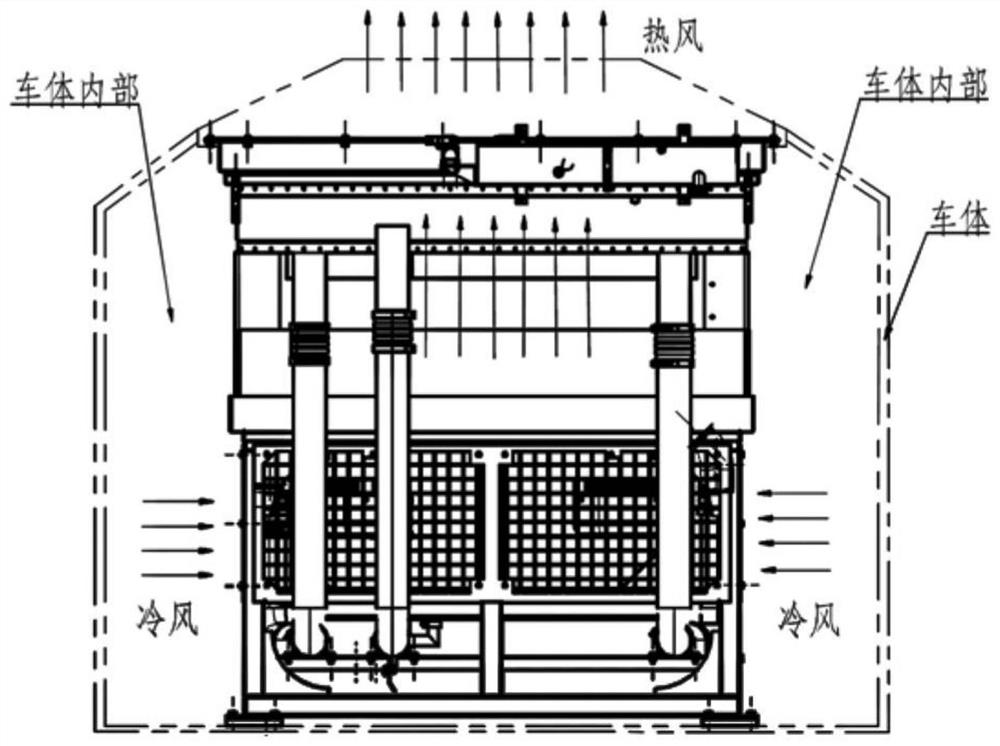

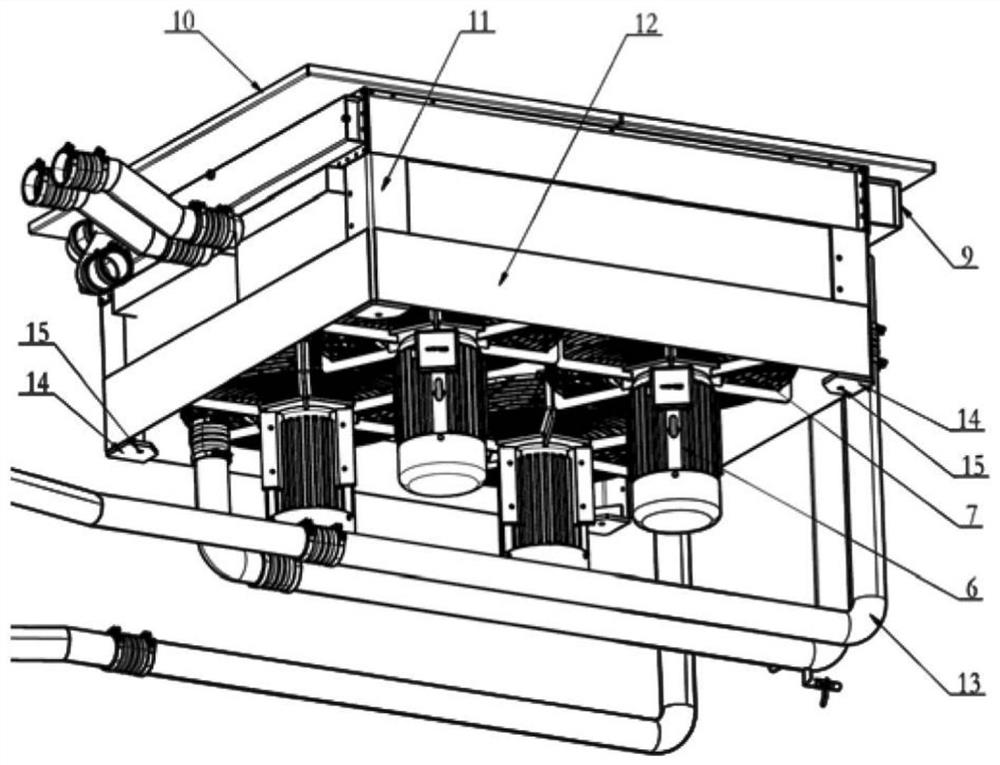

[0038] Such as figure 1As shown, a kind of engine cooling system for railway engineering machinery vehicle of the present invention comprises radiator assembly 1, bracket assembly 2 and movable shutter 5, and radiator assembly 1 is supported by bracket assembly 2, and described cooling The radiator assembly 1 includes a radiator frame 9, a motor 6, a radiator fan 7 and a radiator core 8. The radiator core 8 is horizontally arranged on the top of the radiator assembly 1. The arrangement can effectively compress the installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com