Vacuum pump safety monitoring method and device

A safety monitoring and vacuum pump technology, applied in the direction of pump testing, pump control, liquid variable capacity machinery, etc., can solve problems such as shortened service life, insulation aging, etc., to prolong service life, improve heat dissipation capacity, and monitor working temperature in real time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

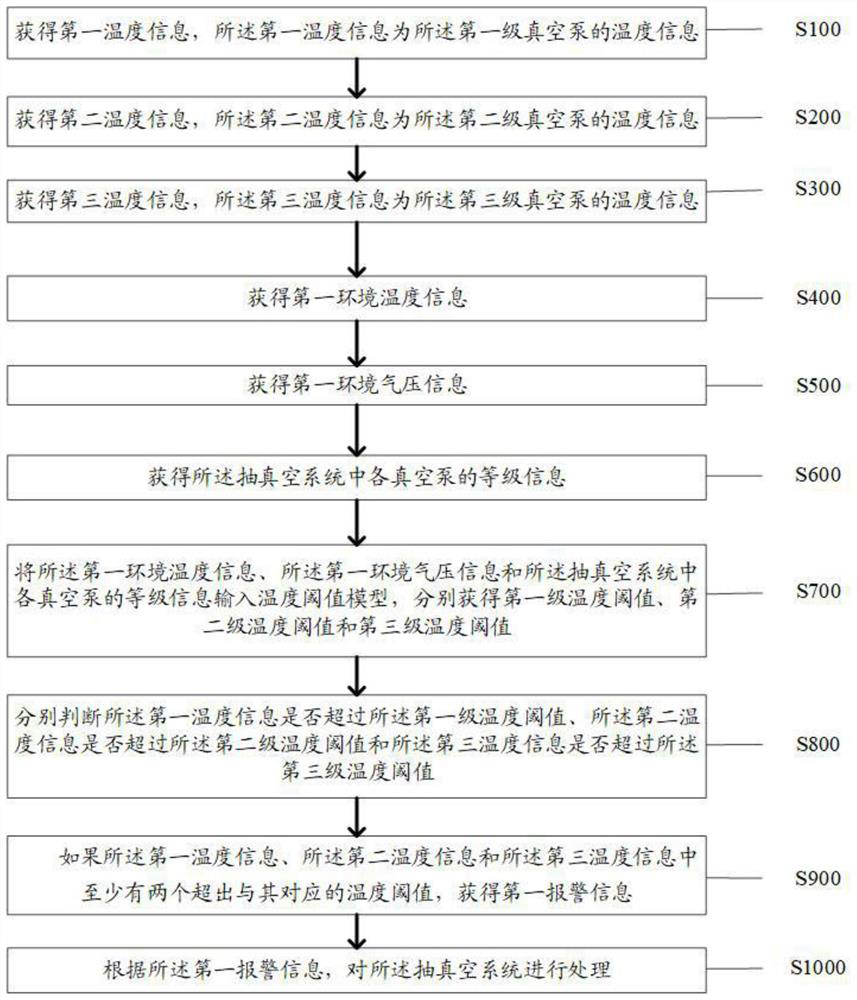

[0024] Such as figure 1 As shown, the embodiment of the present application provides a vacuum pump safety monitoring method, wherein the method includes:

[0025] Step S100: Obtain first temperature information, the first temperature information being the temperature information of the first-stage vacuum pump;

[0026] Step S200: obtaining second temperature information, the second temperature information being the temperature information of the second-stage vacuum pump;

[0027] Step S300: obtaining third temperature information, the third temperature information being the temperature information of the third-stage vacuum pump;

[0028] Specifically, the vacuum pump is a three-stage vacuum pump, including a first-stage vacuum pump, a second-stage vacuum pump, and a third-stage vacuum pump, and the first-stage vacuum pump, the second-stage vacuum pump, and the third-stage vacuum pump are connected end to end in sequence, as shown in the first The first-stage vacuum pump is a...

Embodiment 2

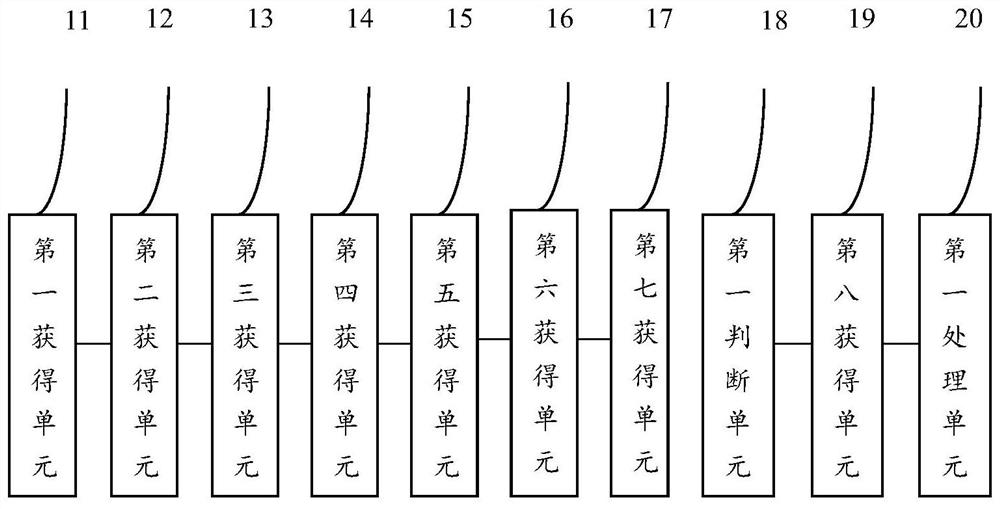

[0084] Based on the same inventive concept as the vacuum pump safety monitoring method in the foregoing embodiments, the present invention also provides a vacuum pump safety monitoring device, such as figure 2 As shown, the device includes:

[0085] A first obtaining unit 11, the first obtaining unit 11 is used to obtain first temperature information, the first temperature information is the temperature information of the first-stage vacuum pump;

[0086] The second obtaining unit 12, the second obtaining unit 12 is used to obtain the second temperature information, the second temperature information is the temperature information of the second-stage vacuum pump;

[0087] A third obtaining unit 13, the third obtaining unit 13 is used to obtain third temperature information, the third temperature information is the temperature information of the third-stage vacuum pump;

[0088] A fourth obtaining unit 14, the fourth obtaining unit 14 is configured to obtain first ambient tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com