Internal-power-driven compact power system for high-speed-ratio pump

A technology of power system and large speed ratio, which is applied in the field of compact power system for large speed ratio pumps, can solve the problems of unrealizable, easy to pollute oil, high or low speed, etc., so as to reduce space occupation and save energy. The effect of installation space and large speed-up ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

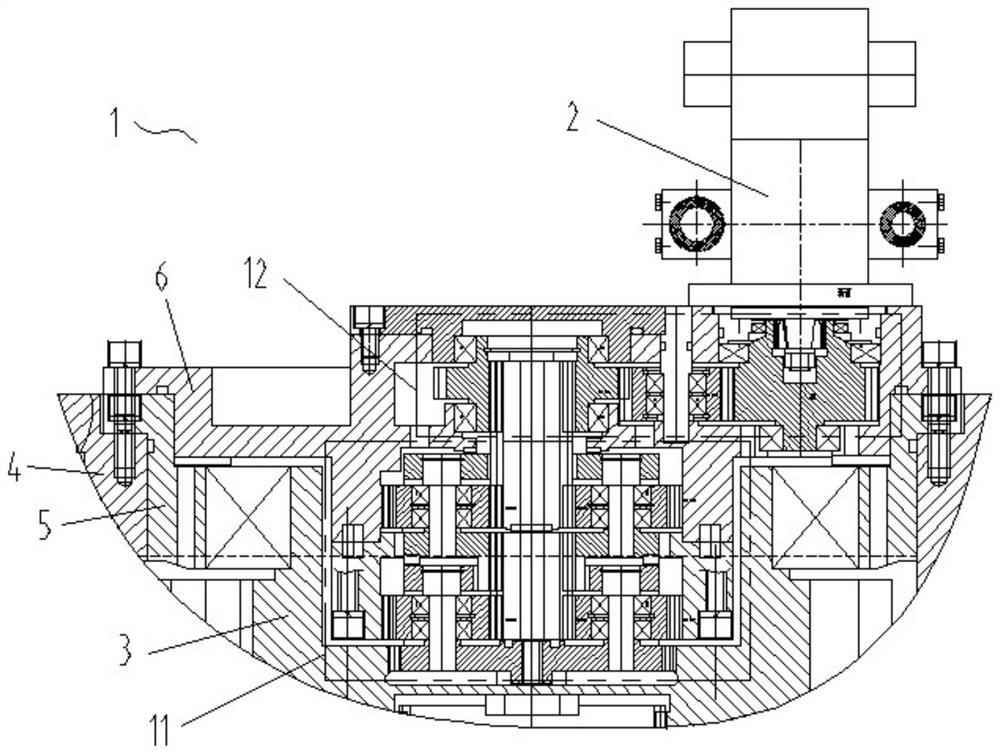

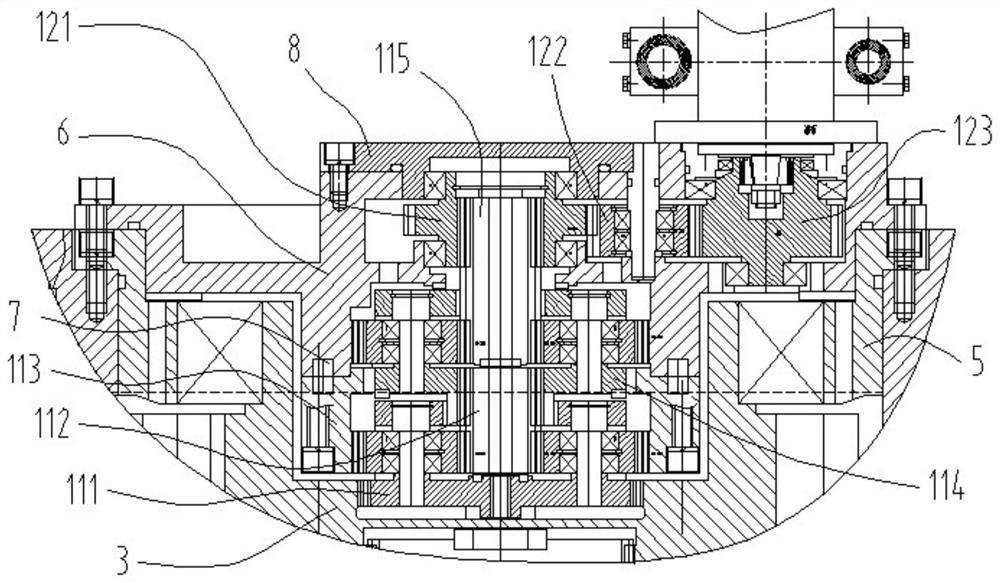

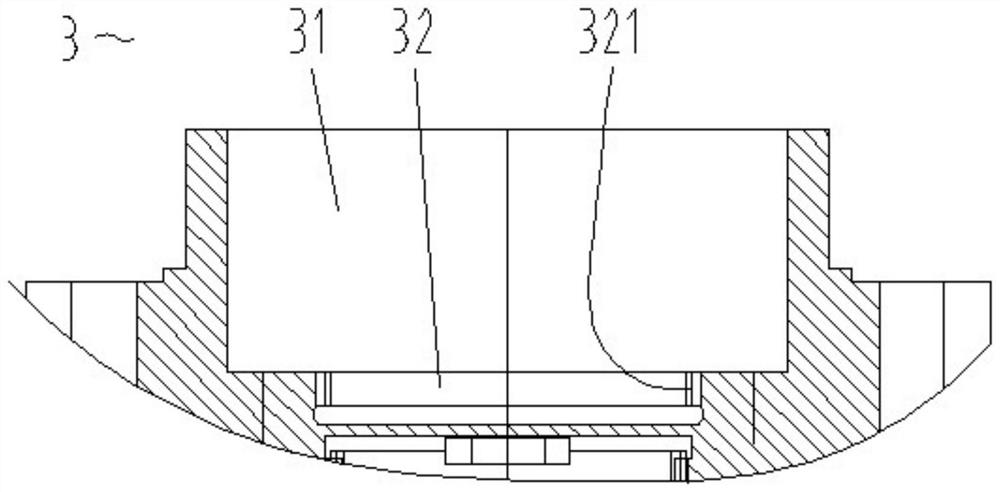

[0033] The invention discloses a compact power system 1 for a pump with a large speed ratio driven by internal power (which may be referred to simply as a compact power system for a pump), which can be used to provide power for a gear pump 2 of a hydraulic system of a coal mining machine, and can replace Conventional pump motor. Such as Figure 1-5 As shown, the pump compact power system includes a two-stage series planetary speed-up mechanism 11 and a one-stage fixed-shaft gear speed-up mechanism 12 that are sequentially connected by transmission. The power input end and the power output end of the two-stage series planetary speed-up mechanism are respectively the planet carrier 111 of the first-stage planetary mechanism and the sun gear 115 of the second-stage planetary mechanism. The power input end and the power output end of the first-stage fixed axis gear speed-up mechanism are the head gear 121 and the end gear 123 respectively. The planet carrier of the first-stage p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com