Hose hole repairing method

A technology of holes and hoses, applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of non-woven fabrics such as external force, long time, poor sealing, etc., to increase fastness and avoid fastness Falling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

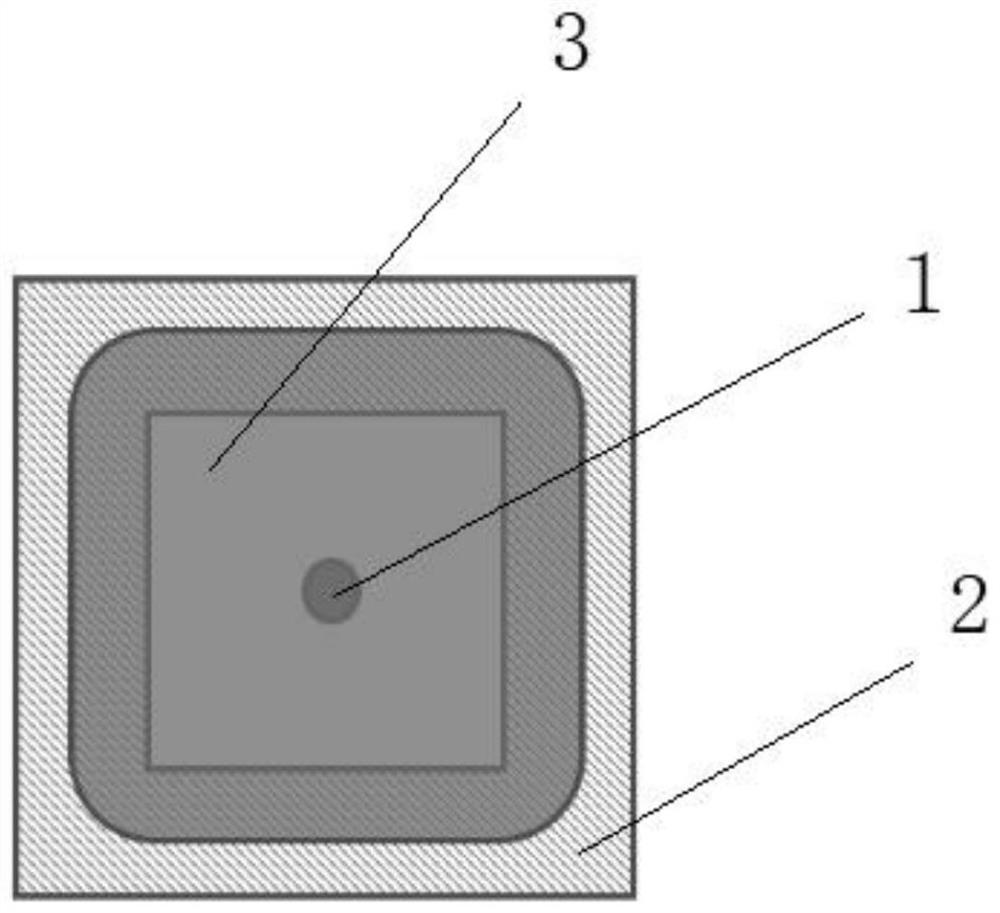

[0021] to combine figure 1 with figure 2 , to describe this embodiment in detail. A kind of hose hole repairing method related to this embodiment comprises the following steps:

[0022] S1 Preparing the sheet patch: cutting the sheet patch according to the size of the hole on the hose; the material used for the sheet patch is a hot-melt material. In this embodiment, the cut sheet patch is rectangular, and the side length is at least 6 cm larger than the maximum diameter of the hole.

[0023] More specifically, the sheet patch is made of PU or PE material, and the hose is a CIPP fiber hose.

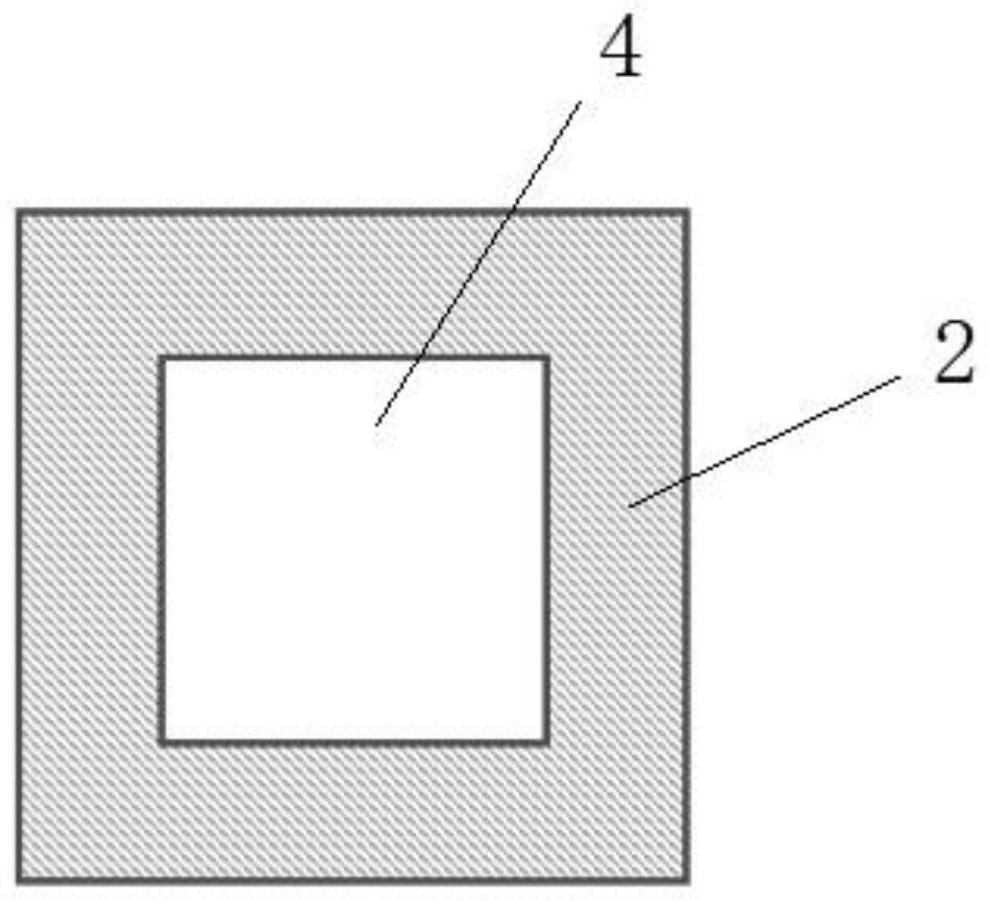

[0024] S2 Preparing a heat insulating sheet: selecting a heat insulating sheet according to the size of the holes, the heat insulating sheet has a hollow part, and the hollow part is rectangular. The heat insulating sheet used in this embodiment is generally in the shape of a zigzag. The length of the inner side of the hollow part of the thermal insulation sheet is at least 4 cm larg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com