A kind of safe discharge method of spent lithium-ion battery

A lithium-ion battery and waste technology, which is applied in the direction of secondary battery charging/discharging, secondary battery, battery recycling, etc., can solve the problems of conductive powder easily adhering to the battery surface, polluting the battery, and easily raising dust, etc., to achieve effective Conducive to large-scale industrial production, simple raw materials and operations, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The invention provides a method for safely discharging waste lithium-ion batteries, which specifically includes the following steps:

[0043] (1) First spread a layer of spherical aluminum particles with a weight of 2kg, a particle size of 5mm, and a resistance of 0.1Ω in the discharge frame, and then waste 2kg of 18650 steel shells with a rated capacity of 3Ah and an open circuit voltage of 3.6V Put the lithium battery evenly into the discharge frame, then add the remaining aluminum particles and mix them by hand. The total weight of the aluminum particles is 4kg;

[0044] (2) Compacting the waste lithium-ion battery and conductive particles with an initial pressurization pressure of 1000Pa, so that the waste lithium-ion battery is discharged; the internal resistance of the discharge frame is calculated according to the pressurized pressure to be 5Ω, according to the discharge frame The internal resistance of the body, the voltage of the used lithium battery and the ra...

Embodiment 2

[0049] The invention provides a method for safely discharging waste lithium-ion batteries, which specifically includes the following steps:

[0050] (1) First spread a layer of cylindrical graphite particles with a weight of 0.5kg, a particle size of 1mm, and a resistance of 20Ω in the discharge frame, and then waste 1kg of soft bags with a rated capacity of 20Ah and an open circuit voltage of 3.7V Put the lithium battery evenly into the discharge frame, then add the remaining graphite particles, and vibrate them by vibration. The total weight of the graphite particles is 1kg;

[0051] (2) Compacting the waste lithium-ion battery and conductive particles with 5000Pa pressurized pressure in advance, so that the waste lithium-ion battery is discharged; the internal resistance of the discharge frame is calculated according to the pressurized pressure to be 0.35Ω, according to the discharge frame The internal resistance, voltage and rated capacity of the waste lithium-ion battery ...

Embodiment 3

[0055] The invention provides a method for safely discharging waste lithium-ion batteries, which specifically includes the following steps:

[0056] (1) First spread a layer of irregular-shaped iron particles with a weight of 2kg, a particle size of 10mm, and a resistance of 10Ω in the discharge frame, and then scrap a 1kg aluminum shell with a rated capacity of 20Ah and an open circuit voltage of 4.0V Put the lithium battery evenly into the discharge frame, then add the remaining iron particles, and vibrate them, the total weight of the aluminum particles is 5kg;

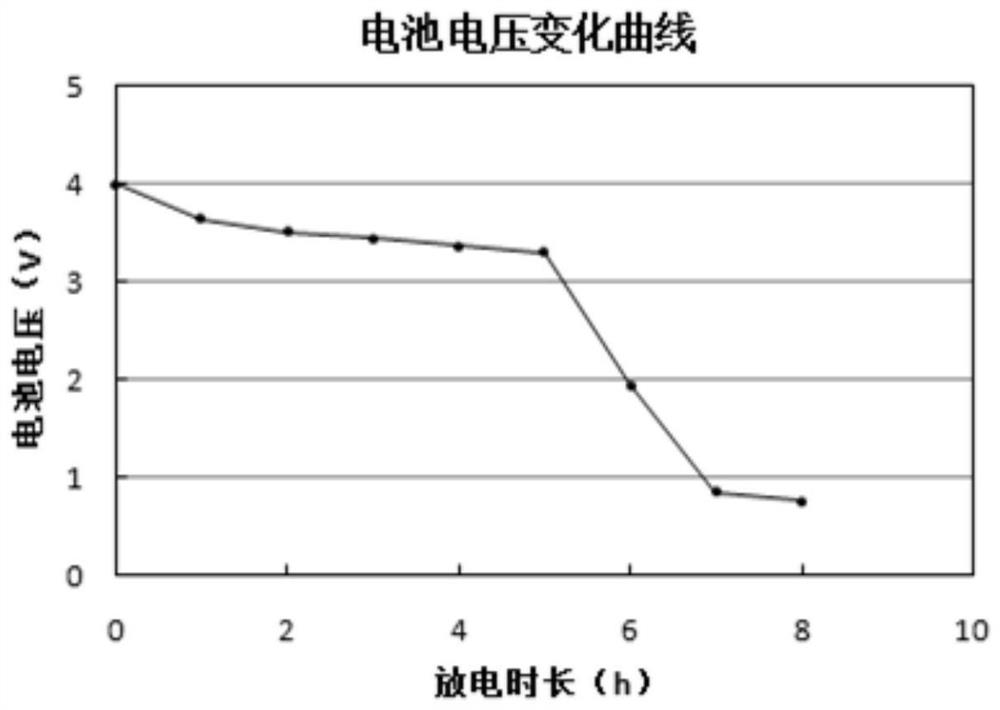

[0057] (2) Compacting the waste lithium-ion battery and conductive particles with 100000Pa pressurized pressure in advance, so that the waste lithium-ion battery is discharged; the internal resistance of the discharge frame is calculated according to the pressurized pressure to be 0.23Ω, according to the discharge frame The discharge rate of the waste lithium-ion battery is calculated as 0.8C based on the internal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com