Vertical printing ink leveling machine

A technology of leveling machine and leveling mechanism, which is applied in the secondary processing of printed circuits and the formation of conductive patterns, etc., can solve the problems of different sizes of holes on the circuit board, depressions on the surface of the ink, and holes caused by the ink sticking, to avoid problems such as The effect of moving or subsidence, good surface flatness, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing of description:

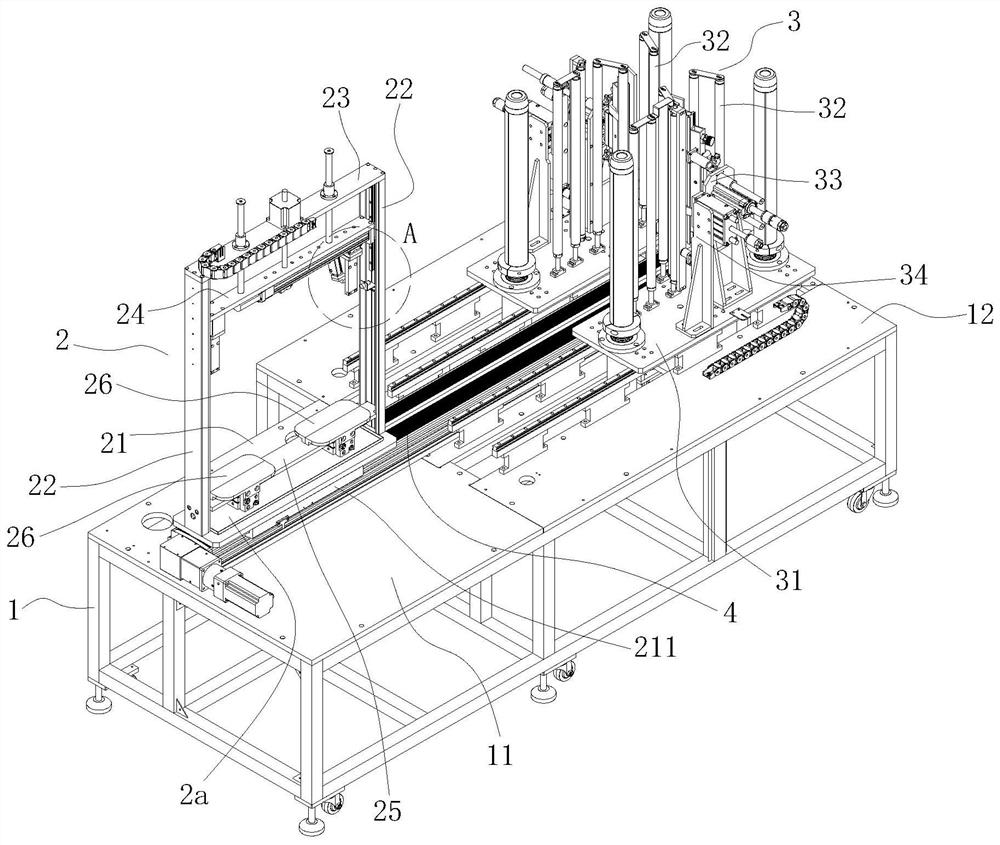

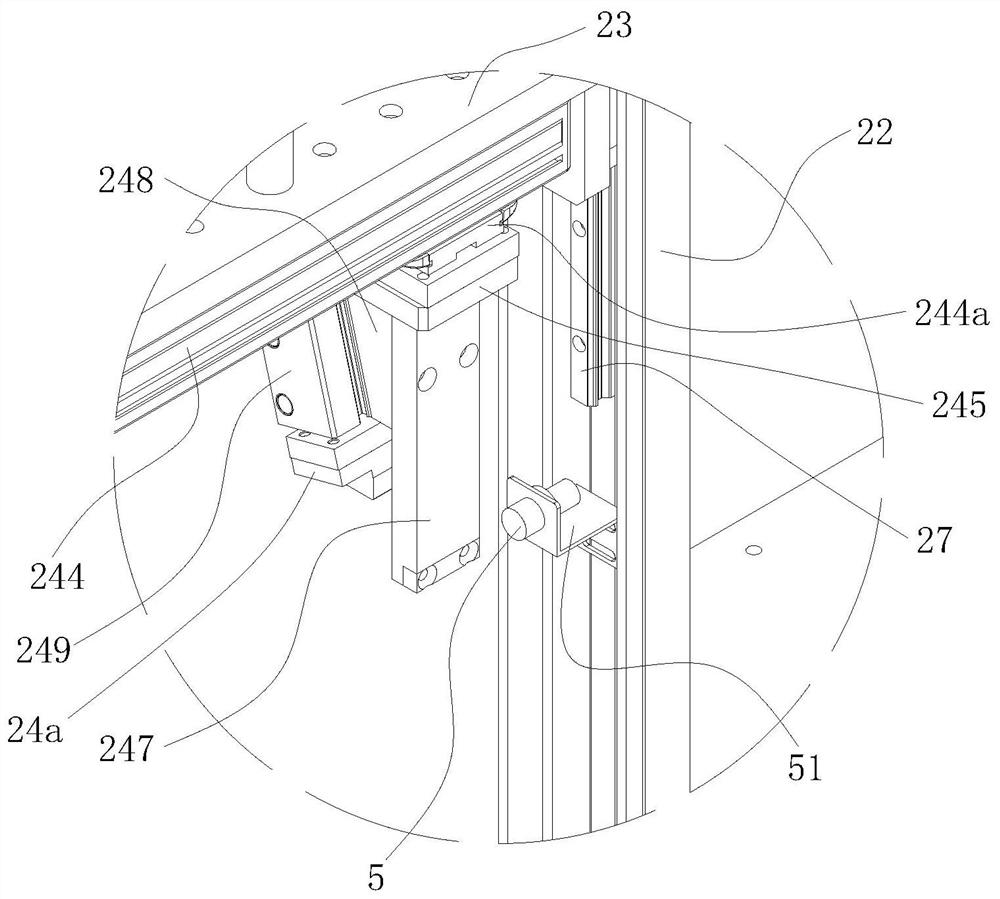

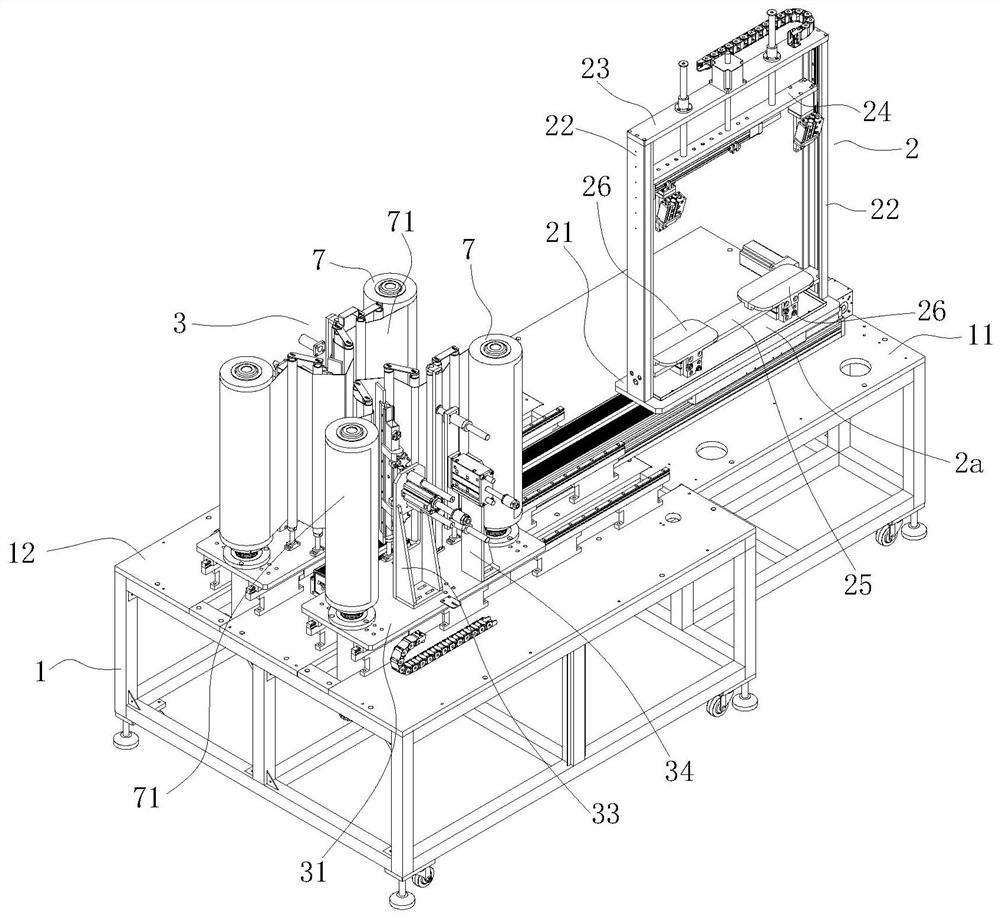

[0031] Such as Figure 1-12 As shown, the present invention relates to a vertical ink leveling machine, comprising a frame 1, wherein one side of the frame 1 is provided with a clamping workbench 11, and the other side is provided with a leveling workbench 12, and on the clamping workbench 11 A clamping and conveying unit 2 is provided, and the clamping and conveying unit 2 is used to vertically clamp the product to be ink-leveled and transport it to the leveling workbench 12, and the said leveling workbench 12 is provided with a vertical ink leveling Unit 3, the ink vertical leveling unit 3 includes a double-head carrying mechanism 31 arranged on the leveling workbench 12, two tensioning mechanisms 32 respectively arranged on both sides of the double-head carrying mechanism 31, and two tensioning mechanisms respectively arranged on the two tensioning mechani...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap