Multi-layer circulation sterilization refrigerator

A multi-layer cycle and refrigerator technology, applied in mechanical equipment, vibration suppression adjustment, food science, etc., can solve the problems of consumption of equipment life, damage of internal parts, base without cushioning and shock absorption, etc., to avoid damage to parts Loss, improve work efficiency, save resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

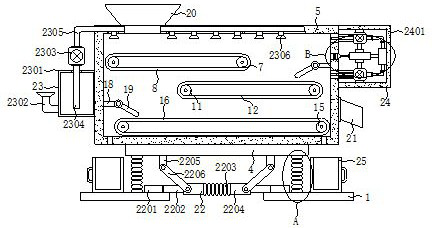

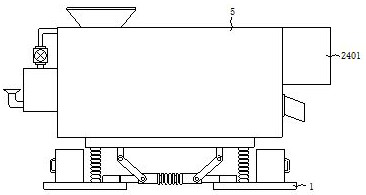

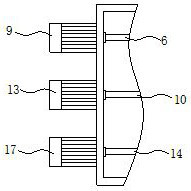

[0029] see Figure 1-6, a multi-layer cycle sterilization refrigerator, including a bottom plate 1, the number of the bottom plate 1 is two groups, the tops of the two groups of bottom plates 1 are welded and installed with telescopic rods 2, and the two groups of telescopic rods 2 are equipped with shock absorbing springs 3, The telescoping ends of two groups of telescopic rods 2 are welded with a top plate 4, and the top of the top plate 4 is welded with a work box 5, and the rear side inner wall of the work box 5 is rotated with a first rotating rod 6, and the number of the first rotating rod 6 is two. group, the first rotating rod 6 is located above the inside of the working box 5, and the first pulley 7 is welded on the first rotating rod 6 of the two groups, and the first belt pulley 7 on the left side is provided with a first conveyor belt 8. A belt pulley 7 is transmission connected with the first belt pulley 7 on the right side by the first conveyor belt 8, and the re...

Embodiment 2

[0032] see Figure 1-6 On the basis of Embodiment 1, the damping mechanism 22 includes a fixed block 2201, a sliding rod 2202, a compression spring 2203, a sliding sleeve 2204, a connecting block 2205 and a connecting plate 2206, and the tops of the two groups of bottom plates 1 are welded and installed with a fixed block 2201, the adjacent side walls of two groups of fixed blocks 2201 are welded with sliding rods 2202, and the sliding rods 2202 are covered with compression springs 2203 and sliding sleeves 2204. The number of sliding sleeves 2204 is two groups, and the two groups of sliding sleeves 2204 are respectively located The two ends of the compression spring 2203, the bottom of the top plate 4 are welded with connecting blocks 2205, the number of connecting blocks 2205 is two groups, and the two groups of connecting blocks 2205 are hingedly equipped with connecting plates 2206 by hinges, the two groups of connecting plates 2206 The free ends are hingedly installed with...

Embodiment 3

[0035] see Figure 1-6 On the basis of Embodiment 1, the sterilizing mechanism 23 includes a water tank 2301, a water inlet bucket 2302, a water pump 2303, a water outlet pipe 2304, an L-shaped water inlet pipe 2305 and a shower nozzle 2306, and a water tank is installed on one side of the working box 5 by welding. 2301, a water inlet bucket 2302 is welded and installed on one side of the water tank 2301, a water pump 2303 is arranged above the water tank 2301, and an outlet pipe 2304 is installed on the water inlet flange of the water pump 2303, and the free end of the water outlet pipe 2304 runs through the water tank 2301 and extend to its inside, the outlet flange of water pump 2303 is equipped with L-shaped water inlet pipe 2305, the free end of L-shaped water inlet pipe 2305 runs through the work box 5 and extends to the inside of the work box 5 top, the L-shaped water inlet A nozzle 2306 is welded on the water pipe 2305, the free end of the nozzle 2306 runs through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com