Aluminum-based metal powder grading treatment equipment applied to powder metallurgy

A grading treatment and powder metallurgy technology, which is applied in the field of aluminum-based metal powder grading treatment equipment, can solve problems such as poor grading accuracy and general overall efficiency, and achieve the effects of improving grading efficiency and optimizing flow channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

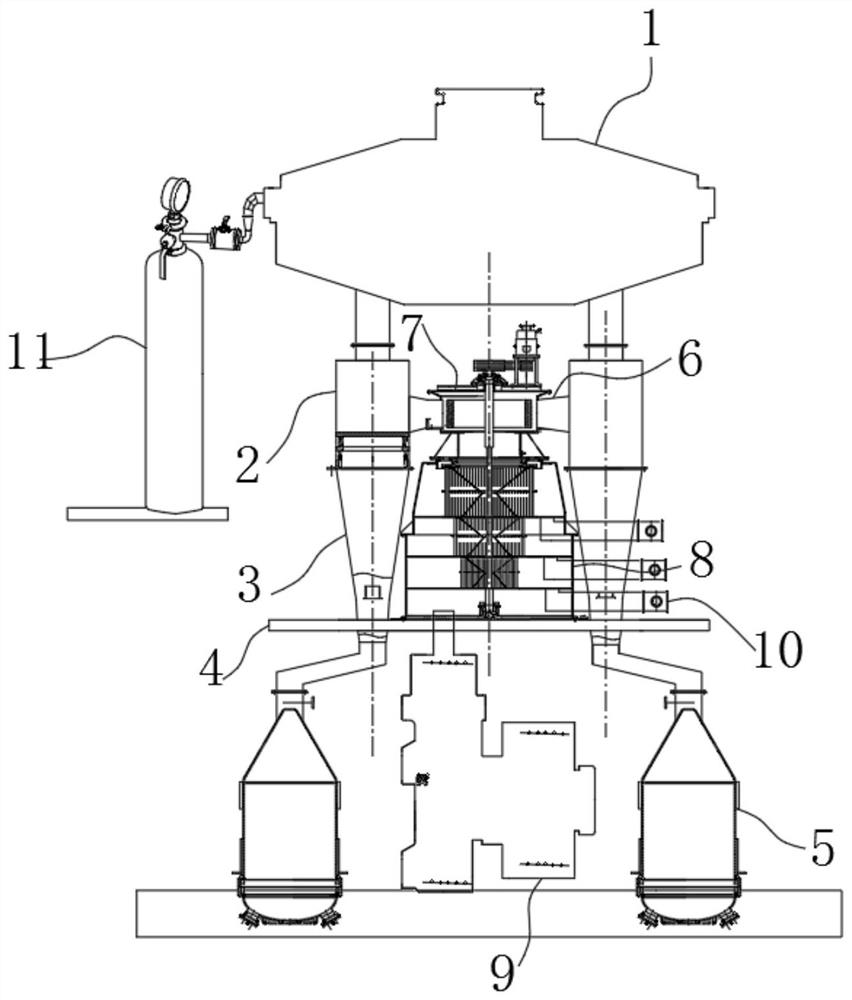

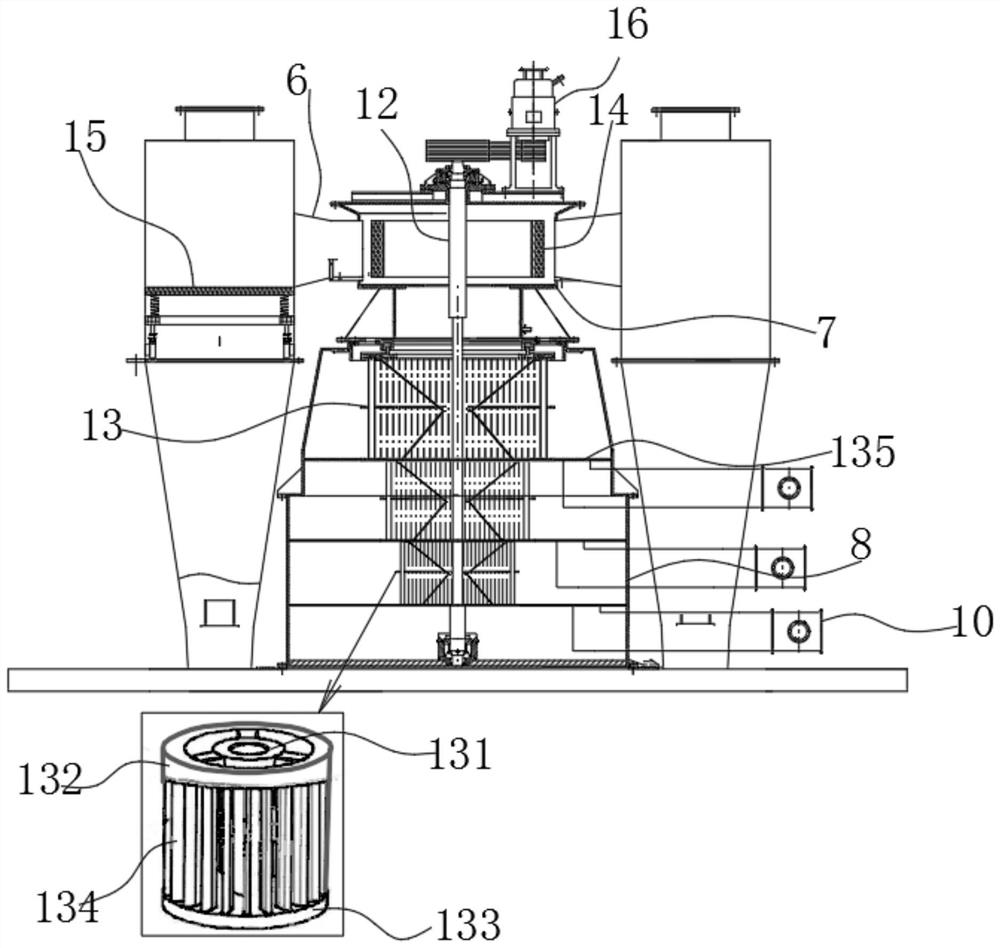

[0040] see Figure 1~4 , in an embodiment of the present invention, an aluminum-based metal powder classification processing equipment applied to powder metallurgy, characterized in that: comprising

[0041] Feeding bin 1;

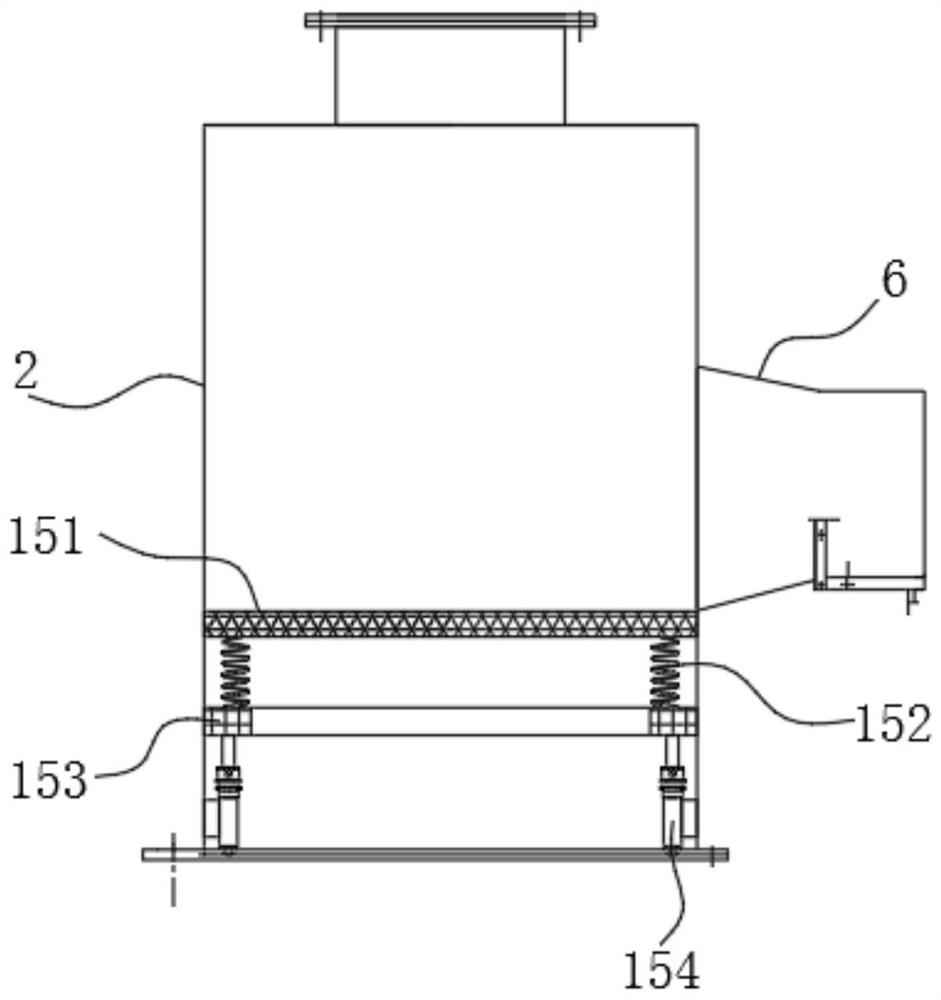

[0042] The screening bin 2 is a plurality of circumferentially distributed ones, and the screening bin 2 is connected to the lower part of the feeding bin 1 by a connecting pipe, and is used to screen the aluminum-based metal powder with a suitable particle size into the collecting hopper 3;

[0043] The crushing bin 7, which is connected to the screening bin 2 by using the guide arm pipe 6, is used to collect the aluminum-based metal powder in the screening bin 2 that has not entered the collecting bucket 3; and

[0044] A grading bin 8 is connected below the crushing bin 7, and continuously classifies the aluminum-based metal powder crushed by the crushing bin 7;

[0045] Moreover, the screening of the screening bin 2 and the grading of the grading bin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com