Point-to-point directional adipose transplantation device

A fat transplantation, point-to-point technology, applied in fixed filter element filters, filtration separation, grain processing, etc., can solve problems such as low efficiency and cumbersome operation, and achieve the effect of easy cleaning and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

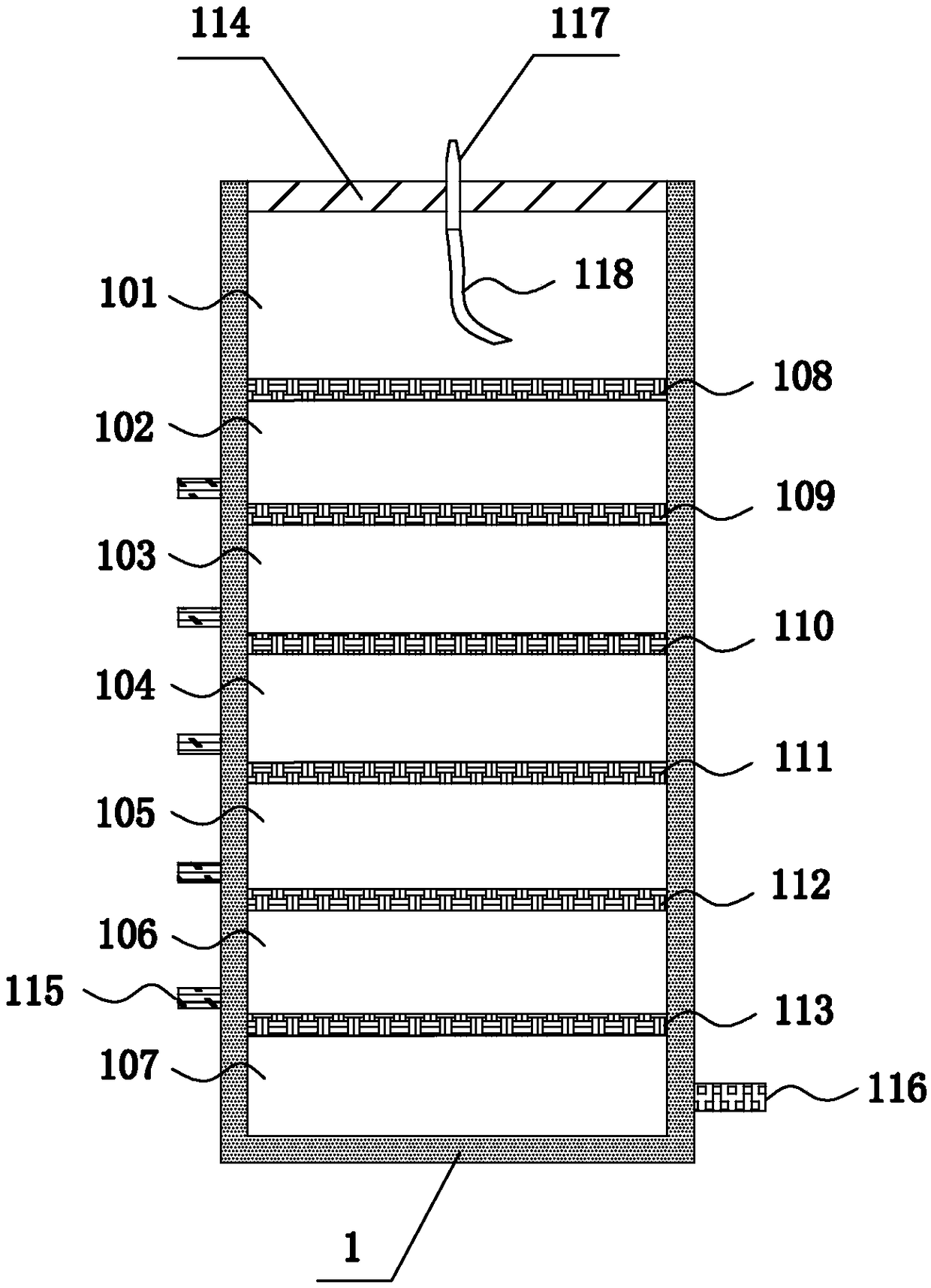

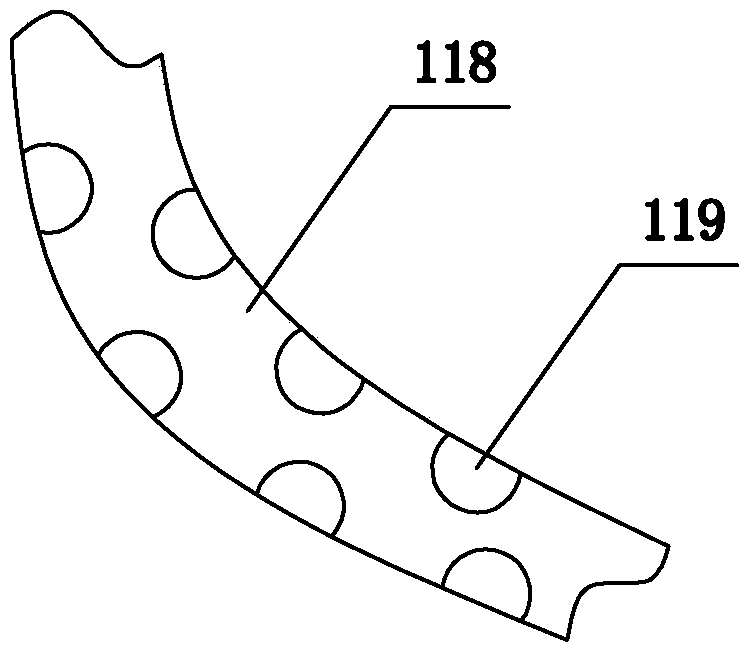

[0023] like Figure 1~2 As shown, Embodiment 1 of the present invention provides a device for point-to-point directional fat transplantation, including a cylinder 1, which includes a storage area 101, a first separation area 102, a second separation area 103, a third separation area 103, and a third separation area from top to bottom. The separation zone 104, the fourth separation zone 105, the fifth separation zone 106, and the suction filtration zone 107 are seven areas in total. Between the two adjacent areas from top to bottom, there are sequentially arranged holes that closely adhere to the inner wall of the cylinder 1 and have sequential apertures. The smaller first filter screen 108, the second filter screen 109, the third filter screen 110, the fourth filter screen 111, the fifth filter screen 112 and the sixth filter screen 113 are six filter screens altogether, and the first filter screen 108 is 20 mesh filter screens, the second filter screen 109 is a 30 mesh filter...

Embodiment 2

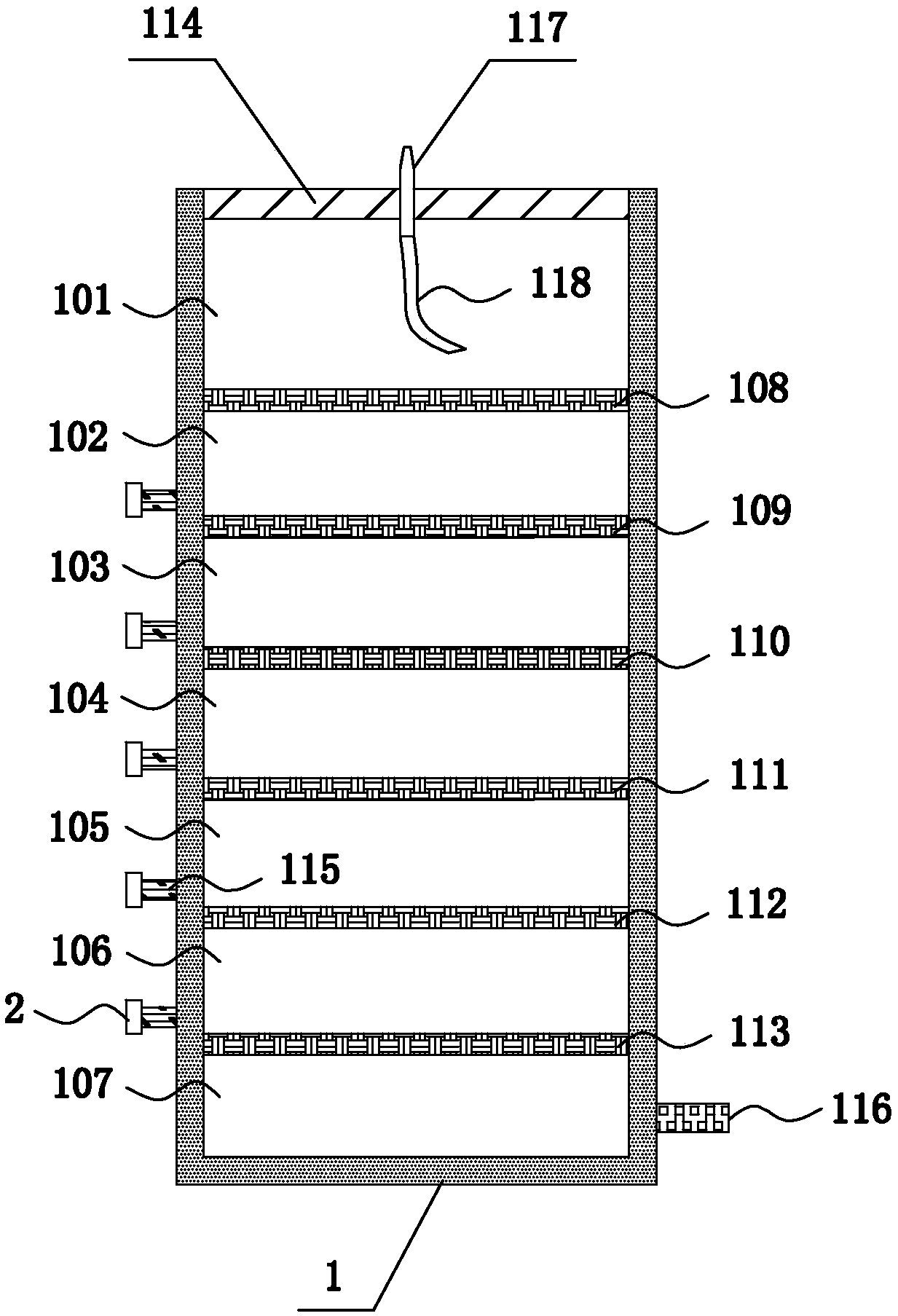

[0027] like Figure 3-4 As shown, this embodiment 2 provides a device for point-to-point directional fat grafting on the basis of embodiment 1, and this embodiment 2 further defines that each syringe connector 115 is provided with a cover 2 at the end. The cover 2 includes a housing 21 threadedly connected to the end of the syringe connector 115 , and a through hole 22 is opened on the housing 21 ; an elastic sealing plug 23 is provided in the housing 21 .

[0028] Insert the needle of the syringe into the elastic sealing plug 23 through the through hole 22 and extend into the corresponding area in the cylinder body 1 to absorb the corresponding fat cells; the elastic sealing plug 23 is made of elastic materials such as rubber, even if it is punctured When the pores appear, they can also deform themselves to close the pores, thereby preventing the outside air from carrying dust and bacteria into the shell and contaminating the fat cells. The housing 21 is threadedly connected...

Embodiment 3

[0031] like Figure 5-6 As shown, this embodiment 3 provides a device for point-to-point directional fat grafting on the basis of embodiment 1, and this embodiment 3 further defines that an elastic sealing ring 3 is provided between two adjacent areas on the cylinder body 1, The top and bottom of the elastic sealing ring 3 are symmetrically provided with a first engaging groove 31 and a second engaging groove 32 for engaging the side wall of the cylinder body 1; The third engaging groove 33 .

[0032] Through the elastic sealing ring 3, each part of the cylinder body 1 and the filter membrane can be disassembled, and the whole device can be disassembled into multiple separate parts that can be spliced and assembled by themselves, so as to facilitate cleaning, sterilization, maintenance and replacement of parts and so on.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com