Method for preparing gutta-percha from eucommia bark

The technology of Eucommia ulmoides peel and eucommia gum is applied in the field of extraction of natural products, which can solve the problems of damage to rubber threads, long production cycle and large amount of sewage, and achieve the effects of reducing usage, improving utilization efficiency and reducing volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

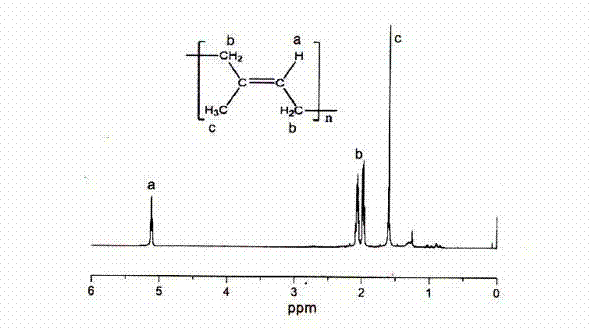

[0027] A method for preparing eucommia gum from eucommia bark, which is made from natural eucommia bark. The molecular weight of eucommia ulmoides gum is 40,000-300,000. The specific preparation steps are as follows:

[0028] Step 1, put the eucommia bark into clean water, wash it, and dry it to make the water content in the eucommia bark

[0029] Less than 5%, reserve;

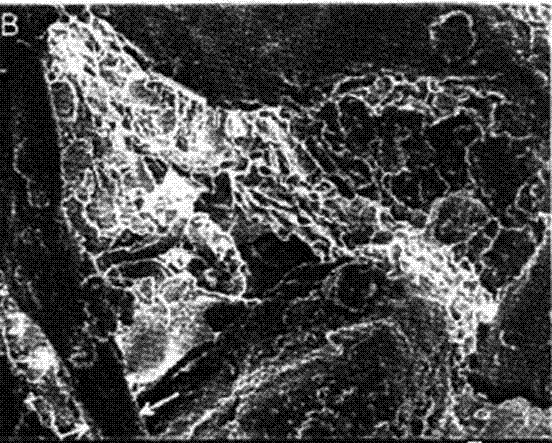

[0030] Step 2, sending the eucommia bark treated in step 1 into an ultrafine pulverizer for ultrafine pulverization, and the pulverized particles are flocs with a particle size of 10 μm;

[0031] Step 3. Send the eucommia bark granules crushed in step 2 into an ultrasonic extraction tank for ultrasonic vibration mixing treatment. The specific treatment requirements are:

[0032] A. Put the petroleum ether solution into the ultrasonic extraction tank first, and then add the pulverized Eucommia bark granules. The weight ratio of the Eucommia bark granules to the petroleum ether solution is 1:6;

[0033] B. Tu...

Embodiment 2

[0038] A method for preparing eucommia gum from eucommia bark, which is made from natural eucommia bark. The molecular weight of eucommia ulmoides gum is 40,000-300,000. The specific preparation steps are as follows:

[0039] Step 1, put the eucommia bark into clear water, wash it, and dry it to make the water content in the eucommia bark

[0040] Less than 5%, reserve;

[0041] Step 2, sending the eucommia bark treated in step 1 into an ultrafine pulverizer for ultrafine pulverization, and the pulverized particles are flocs with a particle size of 50 μm;

[0042] Step 3. Send the eucommia bark granules crushed in step 2 into an ultrasonic extraction tank for ultrasonic vibration mixing treatment. The specific treatment requirements are:

[0043] A. Put the petroleum ether solution into the ultrasonic extraction tank first, and then add the pulverized Eucommia bark granules. The weight ratio of the Eucommia bark granules to the petroleum ether solution is 1:10;

[0044] B. T...

Embodiment 3

[0049] A method for preparing eucommia gum from eucommia bark, which is made from natural eucommia bark. The molecular weight of eucommia ulmoides gum is 40,000-300,000. The specific preparation steps are as follows:

[0050] Step 1, put the eucommia bark into clear water, wash it, and dry it to make the water content in the eucommia bark

[0051] Less than 5%, reserve;

[0052]Step 2, sending the eucommia bark treated in step 1 into an ultrafine pulverizer for ultrafine pulverization, and the pulverized particles are flocs with a particle size of 100 μm;

[0053] Step 3. Send the eucommia bark granules crushed in step 2 into an ultrasonic extraction tank for ultrasonic vibration mixing treatment. The specific treatment requirements are:

[0054] A. Put the petroleum ether solution into the ultrasonic extraction tank first, and then add the pulverized eucommia bark granules. The weight ratio of the eucommia bark granules to the petroleum ether solution is: 1: 16;

[0055] B....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com