Fully automatic high-precision chromaticity and Gamma monitoring and adjustment system and method

A technology for adjusting the system and adjustment method, which is applied in the field of optical systems, can solve problems such as complex operations, and achieve the effects of high automation, low cost, and improved functionality and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

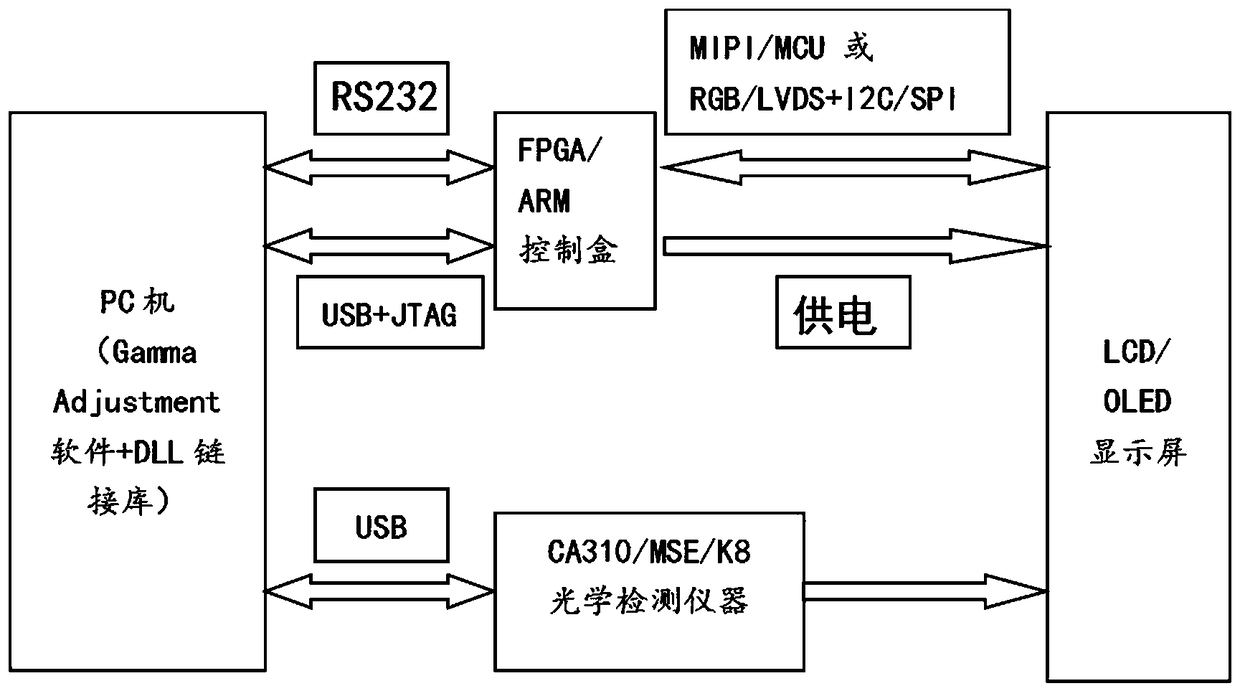

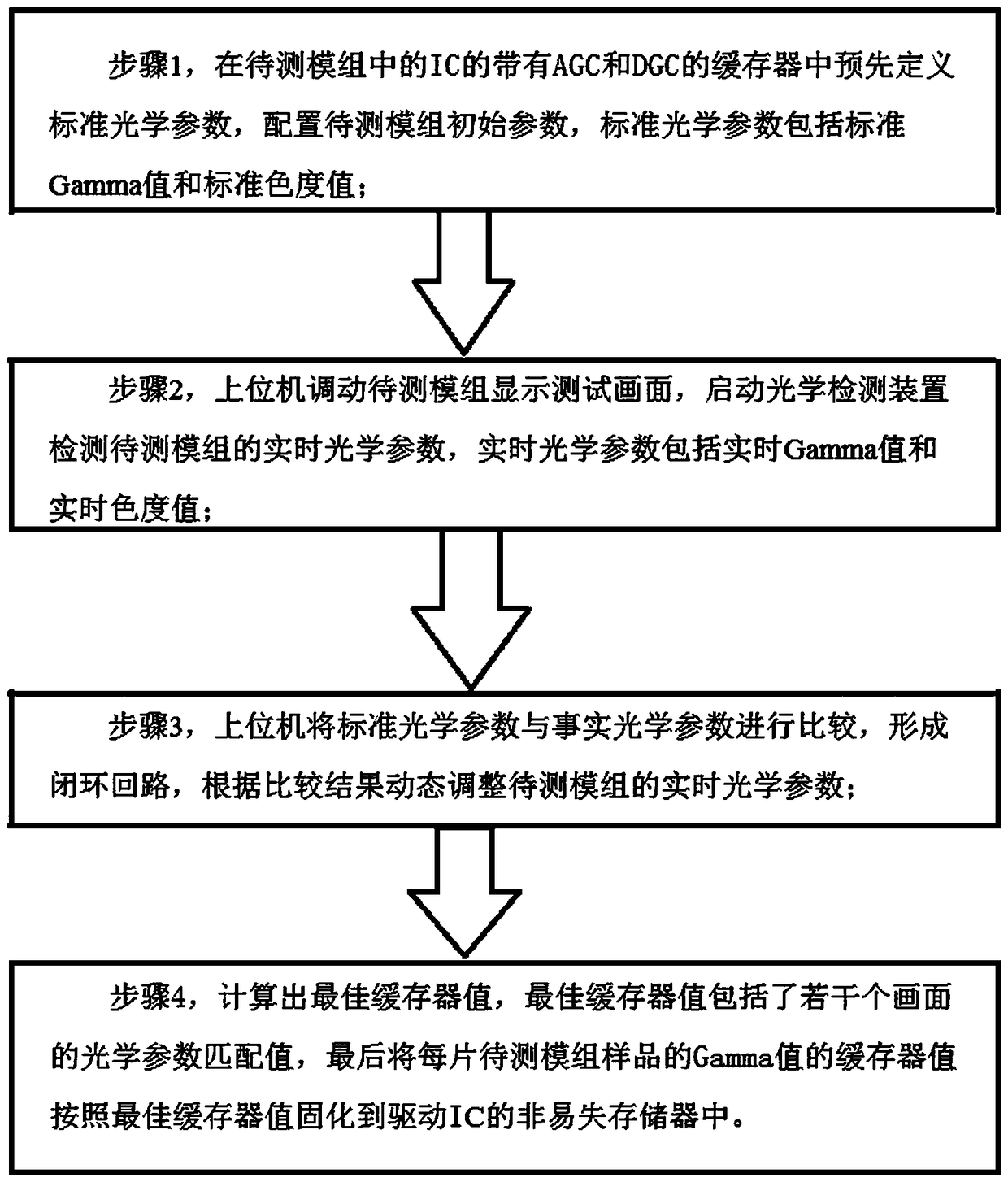

[0036] This embodiment provides a fully automatic high-precision chromaticity and Gamma monitoring and adjustment system, the monitoring and adjustment system includes a host computer loaded with a DLL, a lower computer and an optical detection device for data exchange links with the upper computer; the lower computer Connected to the module to be tested through a data line; the module to be tested is also connected to an optical detection device; the optical detection device is used to detect the optical parameters of the module to be tested in real time; the upper computer sends a picture request to the lower computer, and the lower computer The machine answers and controls the module to be tested to display the corresponding screen.

[0037] Specifically, the lower computer is a programmable module control box. The programmable module adopts FPGA module and ARM module. The host computer (PC) is connected to the lower computer through RS232 and USB+JTAG, and the lower compu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com