Sealed well-type garbage landfill gas emission structure

A gas emission and garbage dump technology, which is applied in the fields of landfill technology, drainage structures, solid waste removal, etc. It can improve the groundwater and air quality around the landfill site, prevent the impact of the ecological environment, and easily manage and control the spillage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

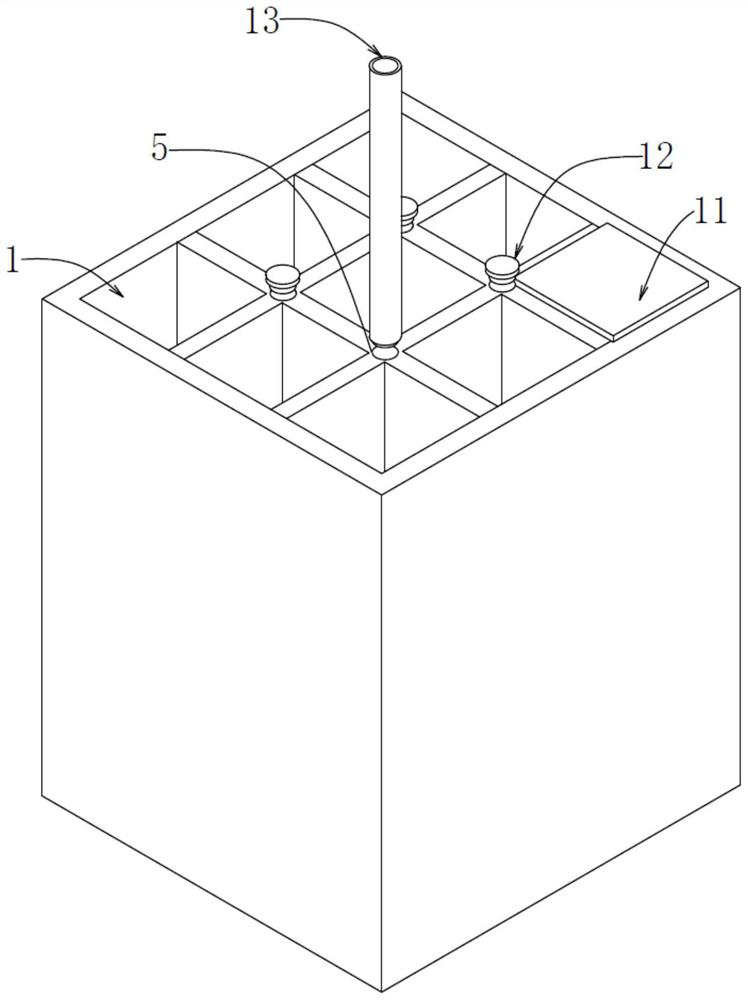

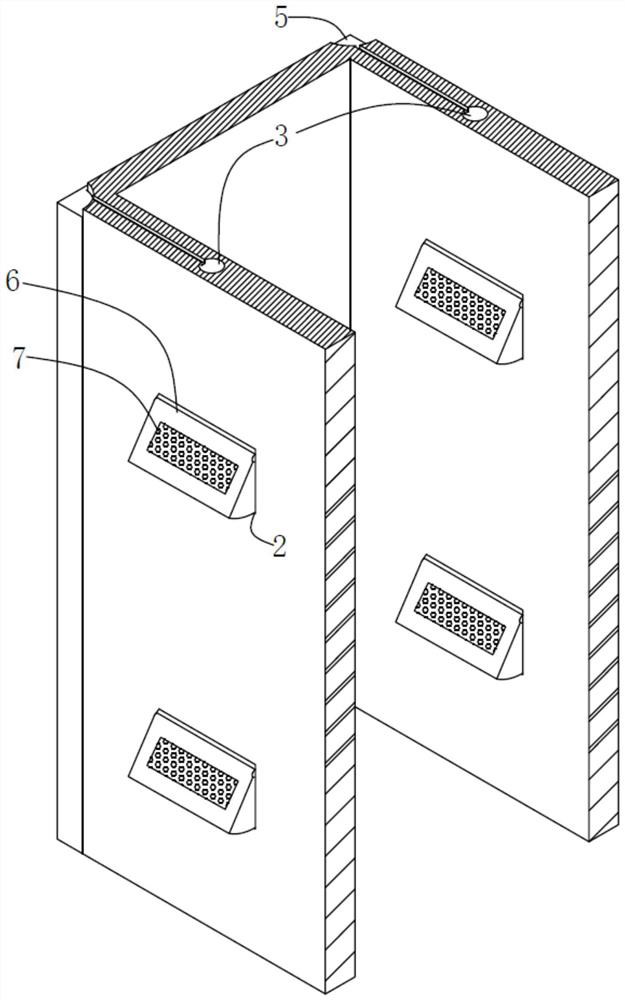

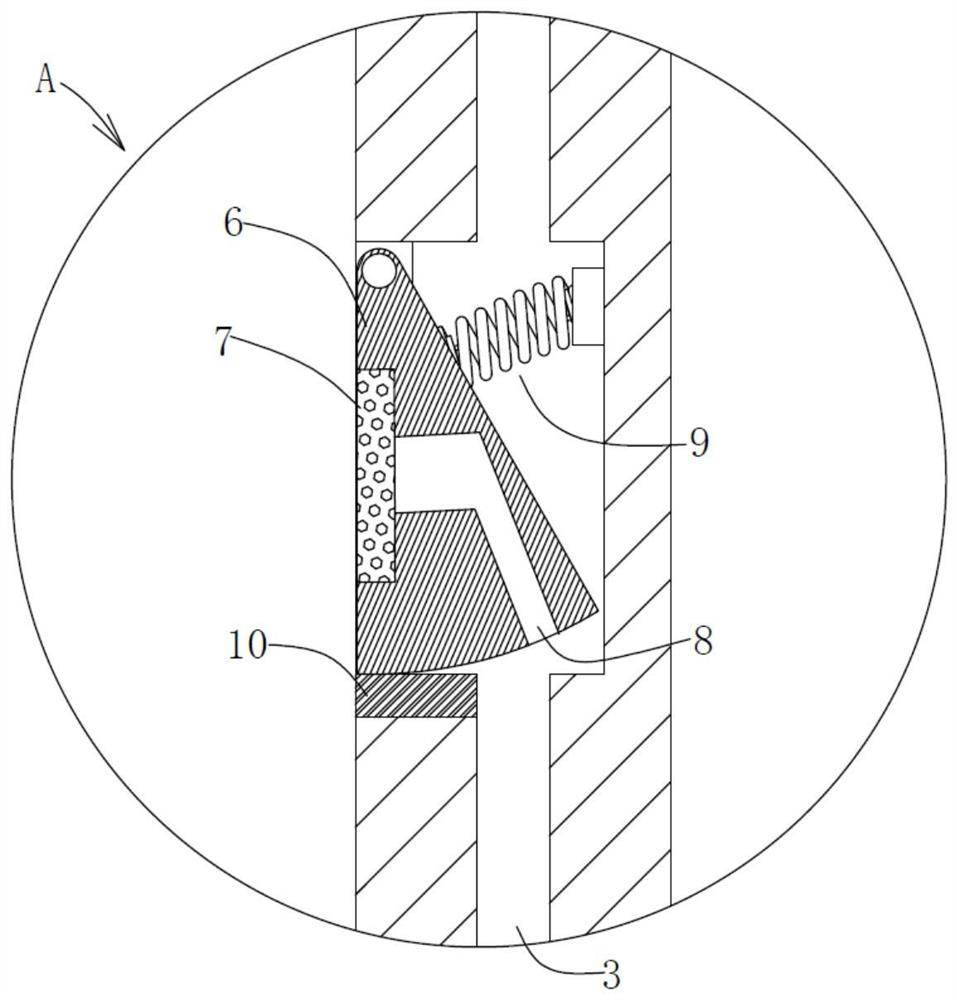

[0025] see Figure 1-5 , the present invention provides a technical solution:

[0026] A sealed well-type landfill gas discharge structure, including several well-type landfill piles 1, the cross-section of the well-type landfill piles 1 is rectangular, and several well-type landfill piles 1 are arranged in an array, and each well-type landfill pile 1 The inner wall of the buried pile 1 is evenly spaced with a number of gas-liquid outlets 2 from top to bottom. The gas-liquid outlets 2 are connected through the separation channel 3 vertically arranged inside the side wall of the well-type landfill 1. The bottom of the separation channel 3 is connected to the seepage The filtrate collection tank 4 is connected, and the upper end of the separation channel 3 is connected with some total gas collection pipes 5 through pipelines;

[0027] The inside of the well-type landfill pile 1 is used for vertically layered landfilling of garbage, and the garbage sent into the inside of the we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com